Trunk line

A trunking and winding technology, applied in the field of loudspeakers, can solve the problems of limited tensile strength of trunks, softening and disconnection of trunks, insufficient stress of trunks, etc., to prolong the life, reduce the risk of disconnection, and increase the effect of tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

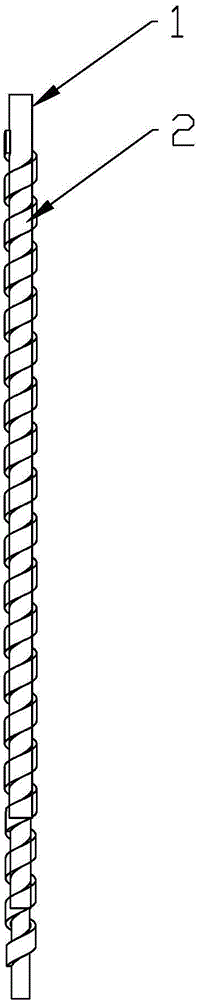

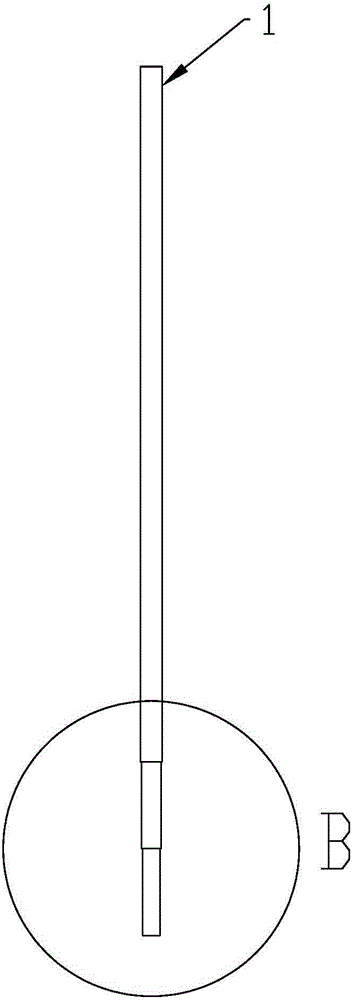

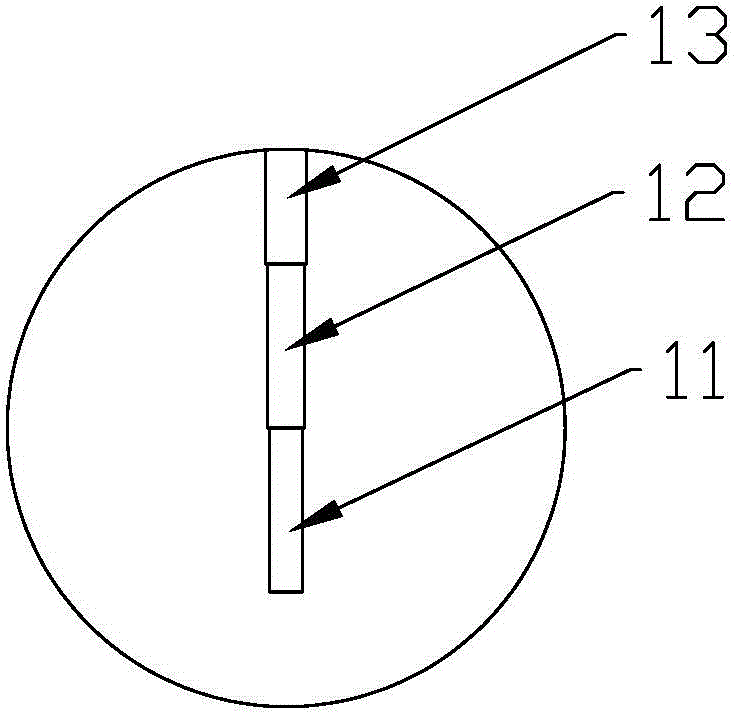

[0021] Figure 1 to Figure 3 A trunk line in the present invention is shown, the trunk line has a simple structure, uses less materials, and has few specifications and good versatility. And compared with general chemical fiber lines, the trunk line contains non-water-absorbing and high-temperature-resistant resin, which makes the trunk line have better performance and longer service life. In addition, the trunk line has a simple structure and better consistency. Moreover, the resistance matching difference of the trunk line is less, so that it is not easy to generate high temperature at the welding point, thereby avoiding the situation of disconnection due to excessive temperature, and further improving the service lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com