Flexible display panel and preparation method thereof and flexible display device

A flexible display and panel technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of increasing the risk of broken wires, large tensile stress of leads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

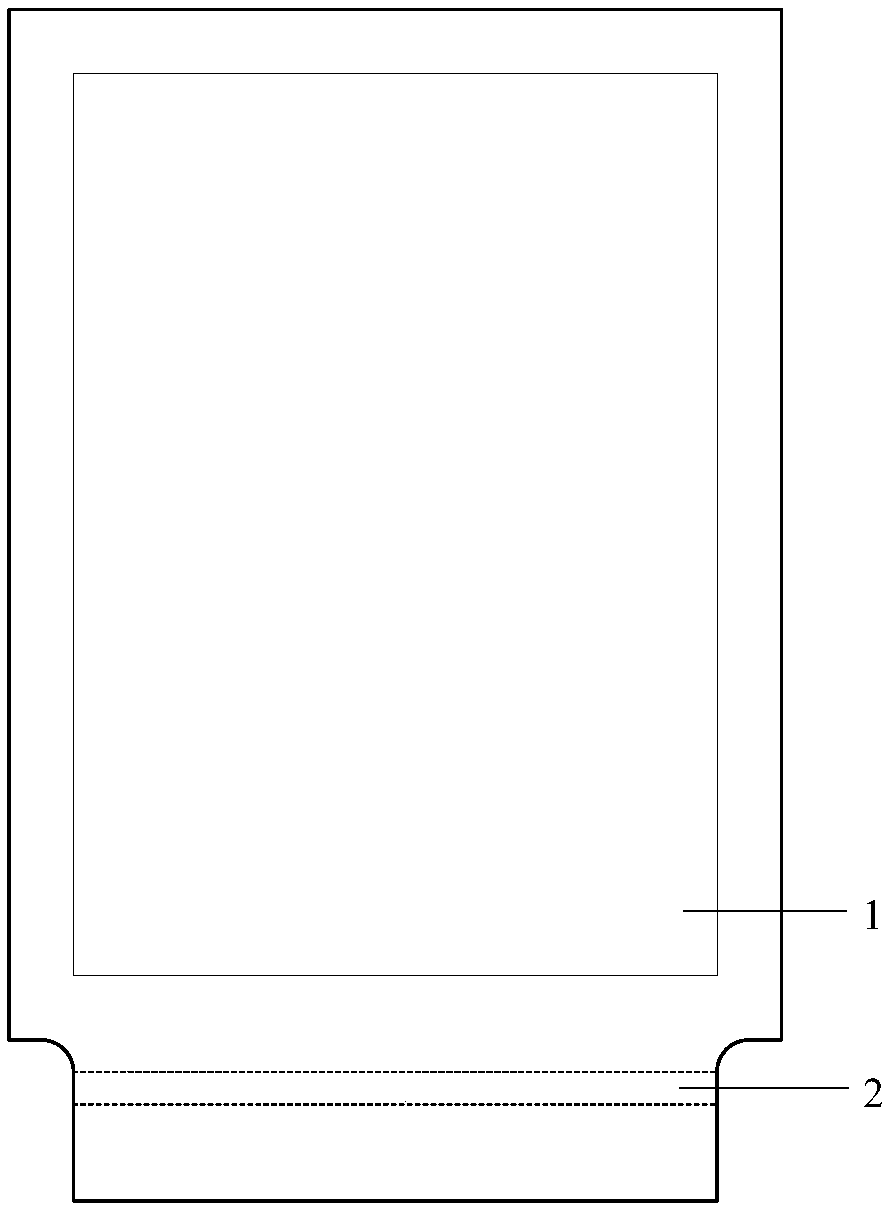

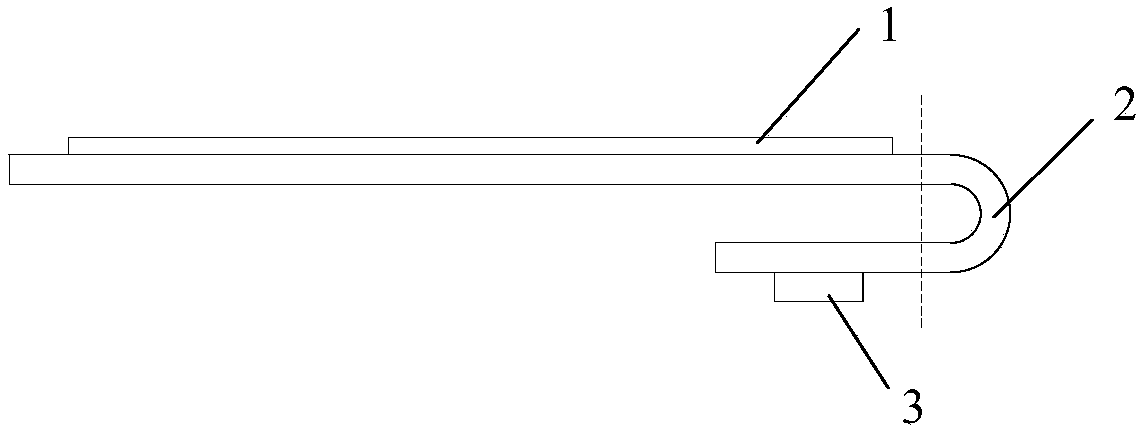

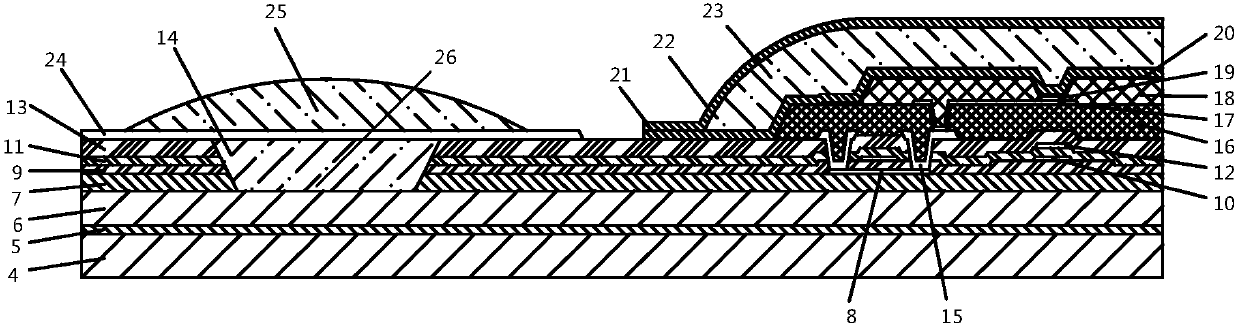

[0059] see image 3 , is a schematic structural diagram of the flexible display panel of Embodiment 1. The flexible substrate can be a three-layer structure in which an inorganic layer 5 is sandwiched between the organic layers 4 and 6 . Each thin film transistor in the sub-pixel array on the flexible substrate may include an isolation buffer layer 7, an active layer 8, a first gate insulating layer 9, a first gate layer 10, and a second gate insulating layer stacked in sequence. 11. The second gate layer 12, the dielectric layer 13, the source-drain metal layer 15 and the planar layer 16. This structure is a double-gate structure; when it is a double-gate structure, the isolation insulating layer includes The dielectric layer, the second gate insulating layer, the first gate insulating layer and the isolation buffer layer. However, in other exemplary embodiments of the present invention, each thin film transistor in the sub-pixel array may also include an isolation buffer l...

Embodiment 2

[0069] see Figure 4 , is a schematic structural diagram of the flexible display panel of the second embodiment. The grooves in this embodiment can be made by stepwise etching. In the bending area, the dielectric layer, the second gate insulating layer, the first gate insulating layer, the isolation layer, and the buffer layer extending to the non-display area can be etched in two steps. In the first step, the dielectric layer, the second gate insulating The insulating layer and the first gate insulating layer are etched to form a wider area, and the second step is to etch the isolation layer and buffer layer to form a relatively narrower area than the upper layer, forming a gentle step with a slope angle of less than 90 degrees, and the etching width It can be 1 mm to 5 mm. The etching process may be dry etching, and the dry etching gas may be CF4 / SF6 / NF3 / CH2F2 / CHF3 or the like.

[0070] The first buffer layer 14 is filled in the groove, and the thickness of the first buff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com