Method for plaiting a fibre web control device and textile machine combination

A control device, fiber strip technology, applied in fiber processing, fiber feeding, textile and papermaking, etc., can solve the problem of unreliable prevention of knot structure, etc., to prevent the formation of knot structure and defective drafting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

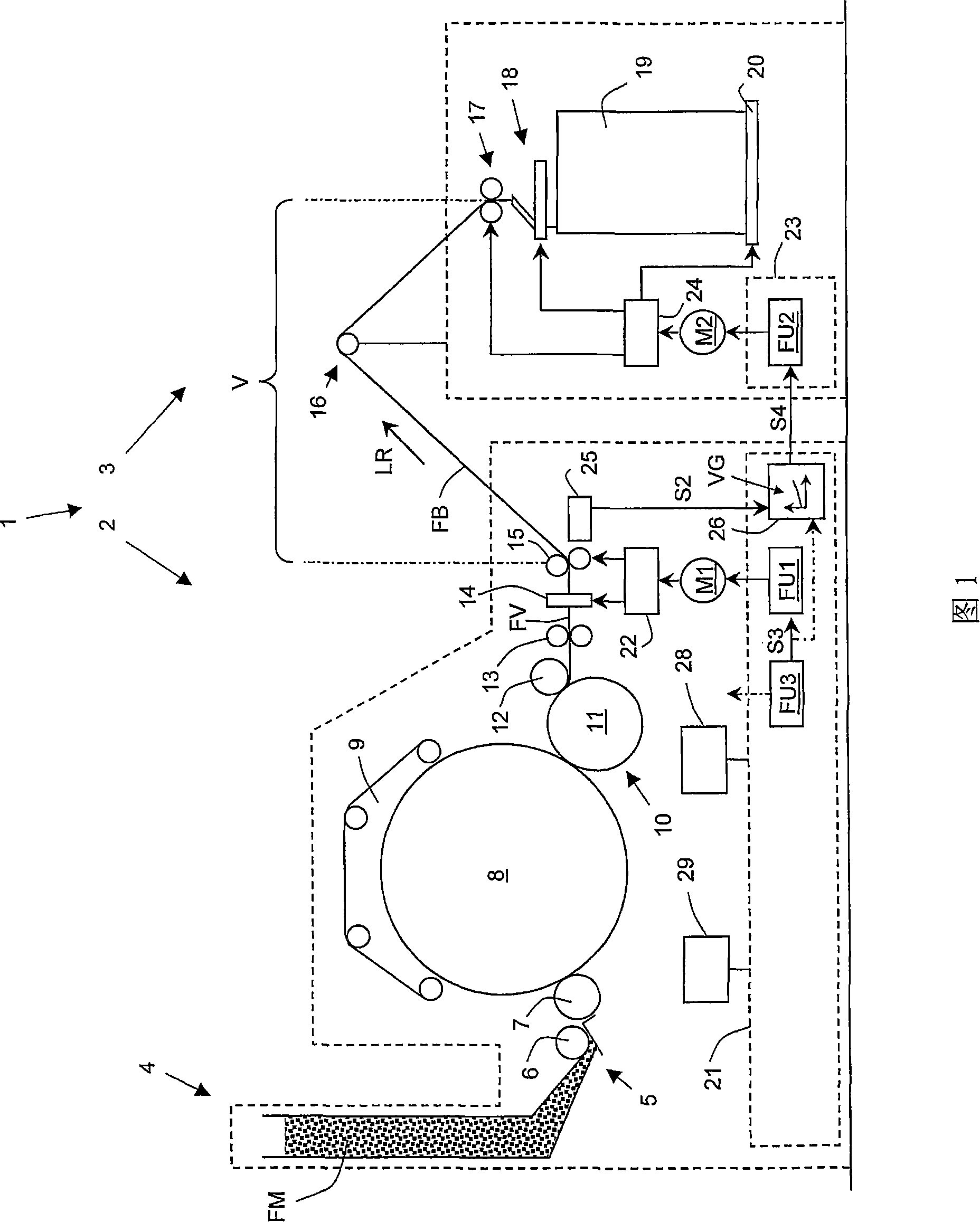

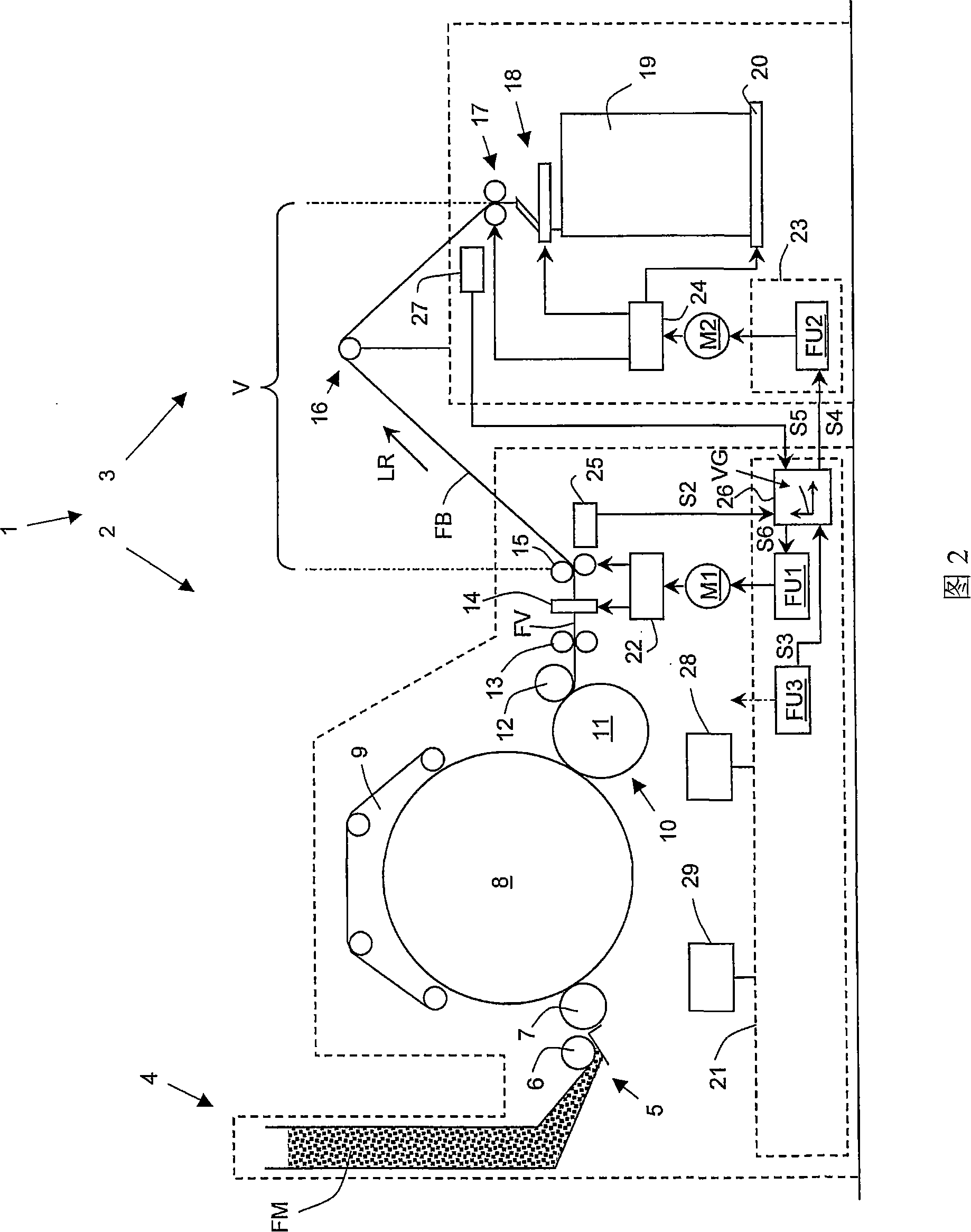

[0044] FIG. 1 shows a spinning machine 1 comprising a spinning preparation machine 2 delivering a fiber sliver and a fiber sliver depositing device 3 . A card (Karde) 2 is shown here as an example of a spinning preparation machine 2 that delivers the fiber sliver. However, the present invention can also be applied to any spinning machine 1 that contains another spinning preparation machine 2 that outputs the fiber sliver, which can be, for example, a carding machine (Krempel), a spinning preparation machine 2 Drawing frame or combing frame.

[0045] The carding machine 2 is provided for carding synthetic or natural fibers, in particular staple fibers, and fiber mixtures formed therefrom. The card 2 comprises a feed trough 4 which is only schematically shown here. This feed trough 4 comprises in its upper part a feeding chute and in its lower part a storage trough in a known manner, with an opener device interposed therebetween, said opener device comprising, for example, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com