Method for preventing steel band from sliding in reversible cold rolling process of 400-series steel plate

A technology for steel strips and steel plates, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as slip marks on the surface of steel coils, automatic speed reduction of production equipment, and impact on production efficiency, so as to improve operating efficiency , Improve productivity and output, increase cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, a method for preventing steel strip from slipping during reversible cold rolling of 430 steel plate, comprising: selecting rolls with a diameter of 85 mm for rolling, and the surface roughness of the rolls in the first three rolling passes is Ra0.4-0.6 , during rolling, the tension at the front of the steel strip is controlled to 50 tons, except for the first pass, the tension at the rear of the steel strip is 47 tons, the discharge speed of the steel strip is controlled at 550 mpm, and the reduction rate of each pass is ≤ 28%; when the system When the first roll slip coefficient Sa≥3.0% is measured, or the other roll slip coefficient Sb≥1.2%, the rolling system is controlled to reduce the discharge speed of the steel strip until the measured slip coefficient reaches the set range.

Embodiment 2

[0013] Embodiment 2, a method for preventing steel strip from slipping during reversible cold rolling of 439 steel plate, comprising: selecting rolls with a diameter of 80 mm for rolling, and the surface roughness of the rolls in the first three rolling passes is Ra0.4-0.6 , during rolling, the tension at the front of the steel strip is controlled to 55 tons, except for the first pass, the tension at the rear of the steel strip is 53 tons, the discharge speed of the steel strip is controlled at 520 mpm, and the reduction rate of each pass is ≤ 28%; when the system When the first roll slip coefficient Sa≥3.0% is measured, or the other roll slip coefficient Sb≥1.2%, the rolling system is controlled to reduce the discharge speed of the steel strip until the measured slip coefficient reaches the set range.

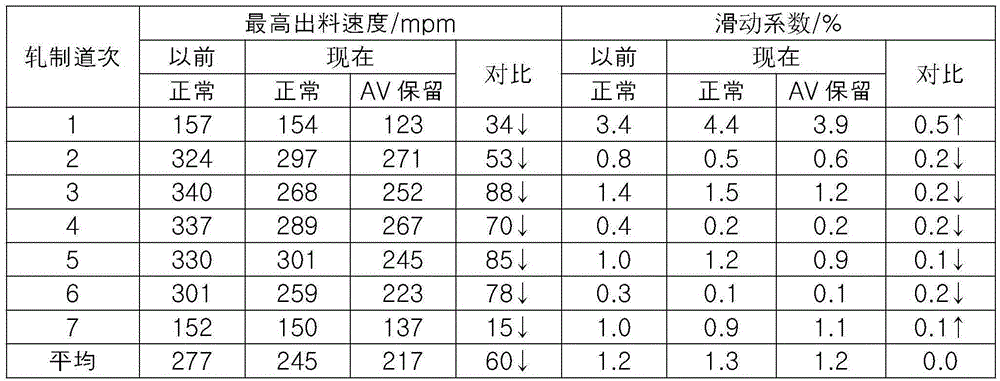

[0014] The following table lists the comparison of the average value of relevant data rolled by this method and the traditional method for 400 series (taking AV-short linear fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com