Array substrate and preparation method thereof

An array substrate and a substrate technology, which are applied in the field of array substrates and their preparation, can solve the problem that the brightness uniformity of the screen cannot be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

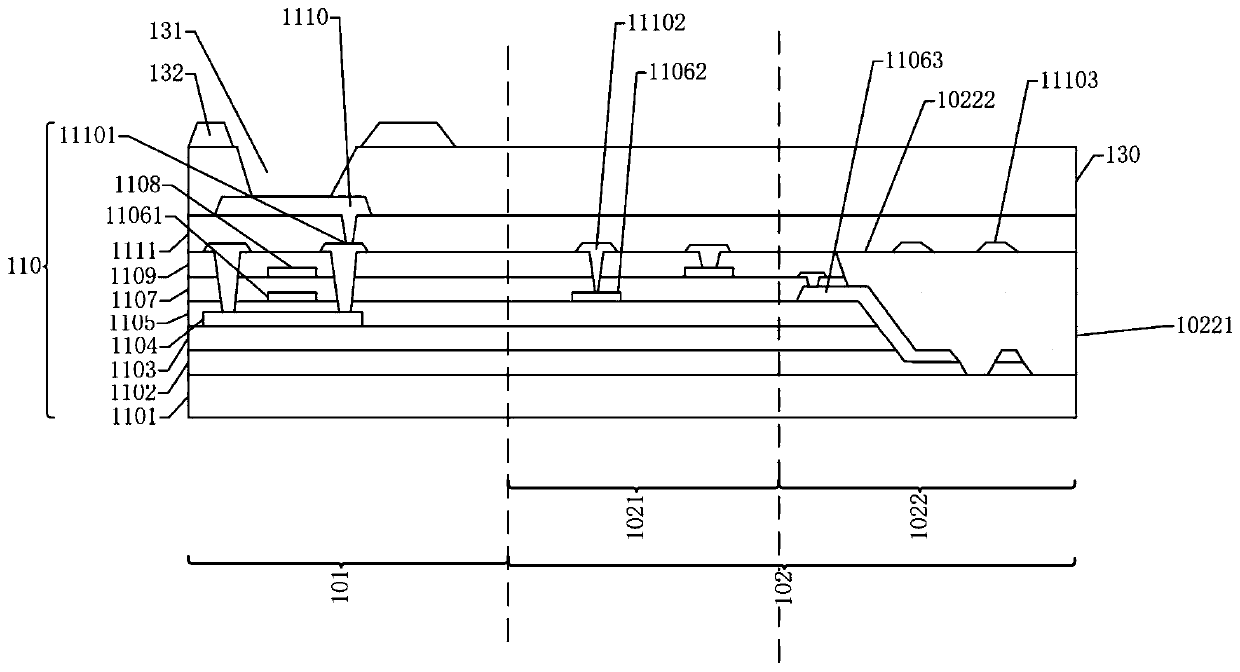

[0095] In this embodiment, the array substrate of the present invention includes a thin film transistor layer 110 , an anode layer 120 and a pixel definition layer 130 .

[0096] Such as figure 1 As shown, wherein, the thin film transistor layer 110 includes a substrate 1101, a barrier layer 1102, a buffer layer 1103, an active layer 1104, a first insulating layer 1105, a first gate layer 1106, a second insulating layer 1107, a second gate An electrode layer 1108 , a third insulating layer 1109 , a source-drain electrode layer 1110 and a planar layer 1111 .

[0097] The barrier layer 1102 is provided on the substrate 1101, and the material used for the barrier layer 1102 includes one or more of silicon oxide, silicon nitride, silicon oxynitride and amorphous silicon, and is mainly used to block water and oxygen. , preventing water and oxygen from corroding the array substrate.

[0098] The buffer layer 1103 is disposed on the barrier layer 1102, and the buffer layer 1103 is ...

Embodiment 2

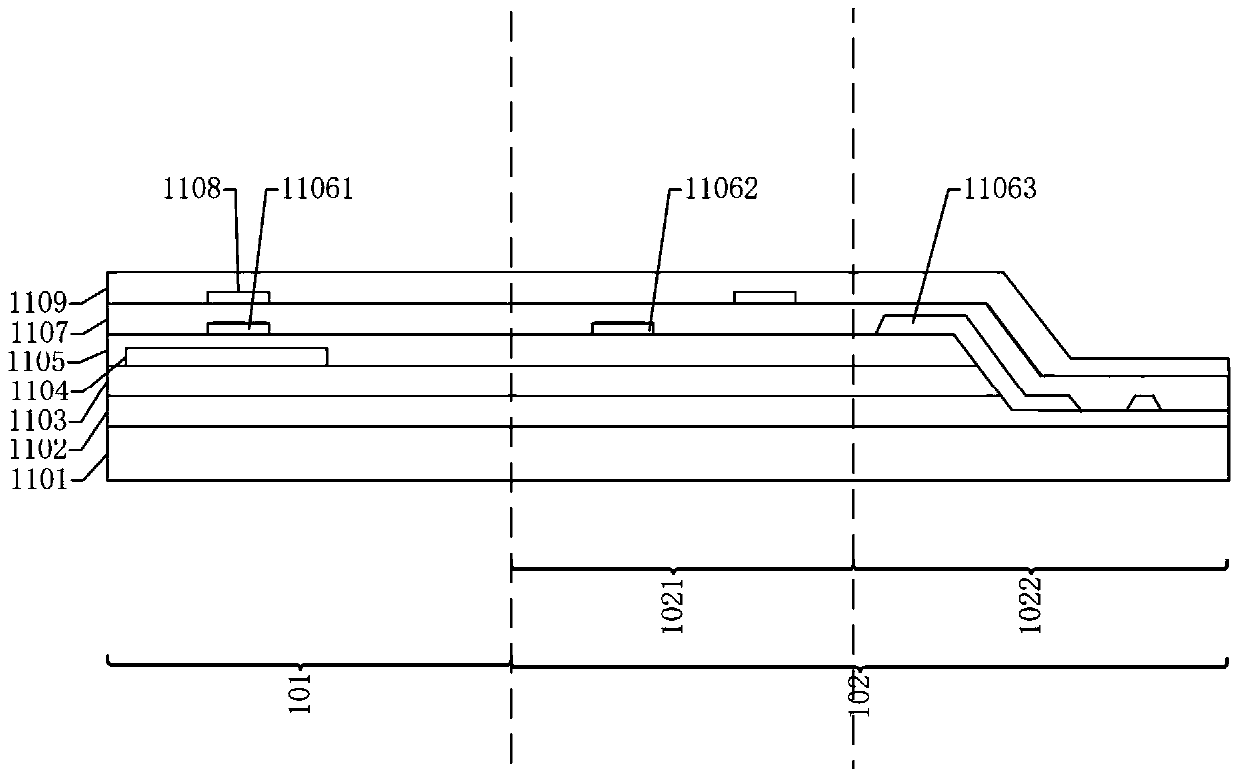

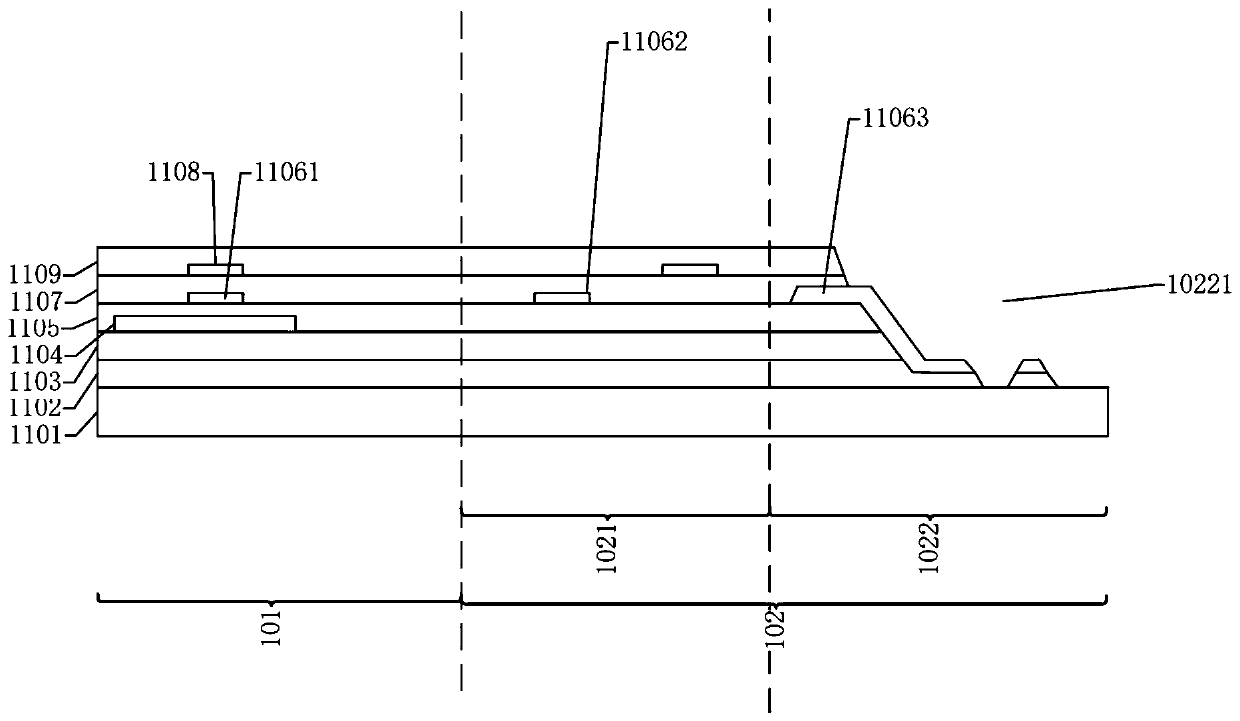

[0139] Such as Figure 5 As shown, in this embodiment, the structure of the array substrate of the present invention is generally similar to that of the array substrate in Embodiment 1, the difference is that the second gate layer 1108 in the array substrate in this embodiment includes The fourth metal segment 11081 , the fifth metal segment 11082 and the sixth metal segment 11083 .

[0140] The fourth metal segment 11081 is disposed on the second insulating layer 1107 in the display area 101 and corresponds to the active layer 1104 . The fifth metal segment 11082 is disposed in the fan-out region 1021, the sixth metal segment 11083 is disposed in the bonding region 1022, wherein the first gate layer 1106 is disposed in the first on the insulating layer 1105 and corresponding to the second gate layer 1108 .

[0141] An opening 10221 is provided in the bonding region 1022, and the opening 10221 penetrates through the third insulating layer 1109, the second insulating layer 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com