GaN-based III-V compound semiconductor LED (light emitting diode) epitaxial wafer and production method thereof

A technology for LED epitaxial wafers and growth methods, which is applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as the decline of optoelectronic properties such as the antistatic ability of LED chips, the easy formation of defects in the epitaxial layer, and the impact on the yield of chip products. Improve the internal quantum efficiency, enhance the antistatic ability, and improve the effect of compound efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

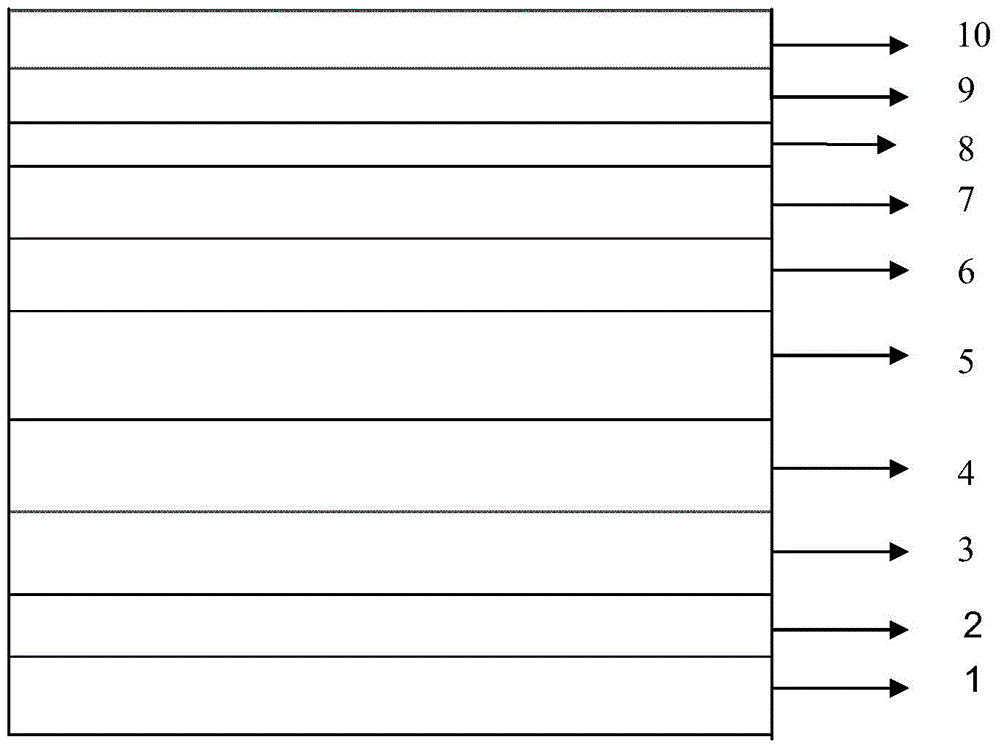

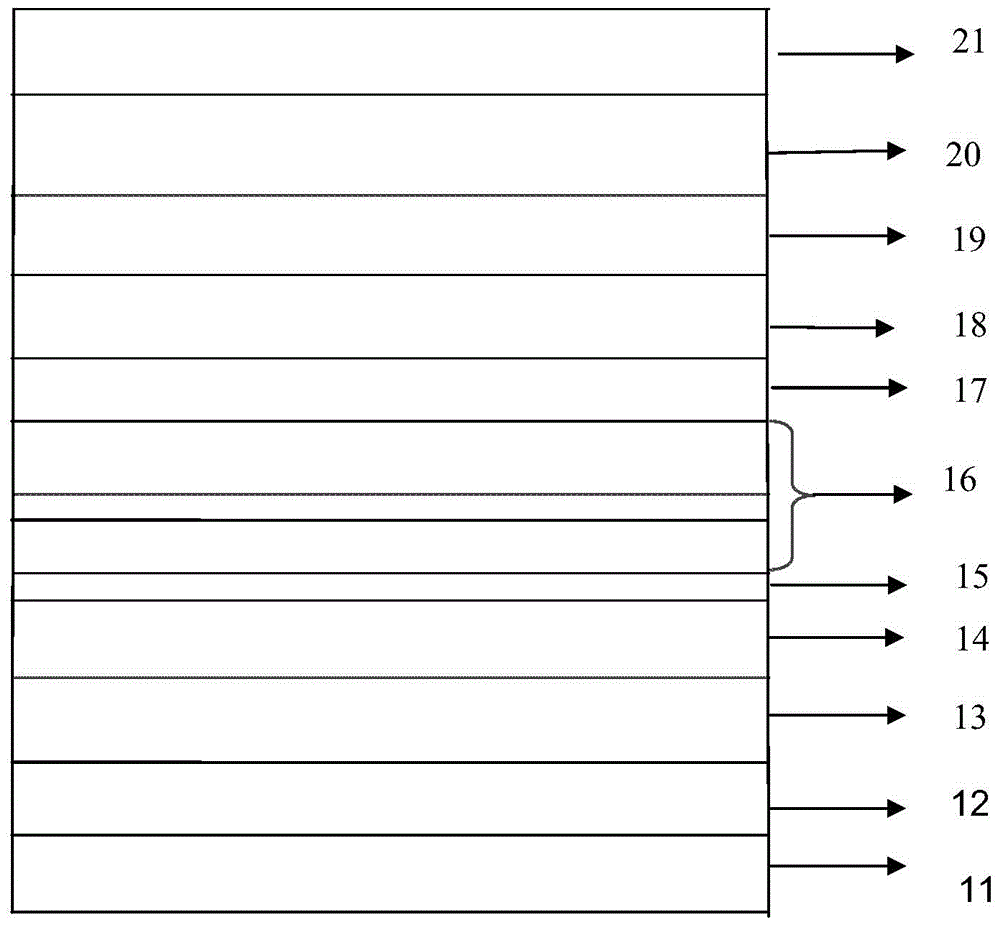

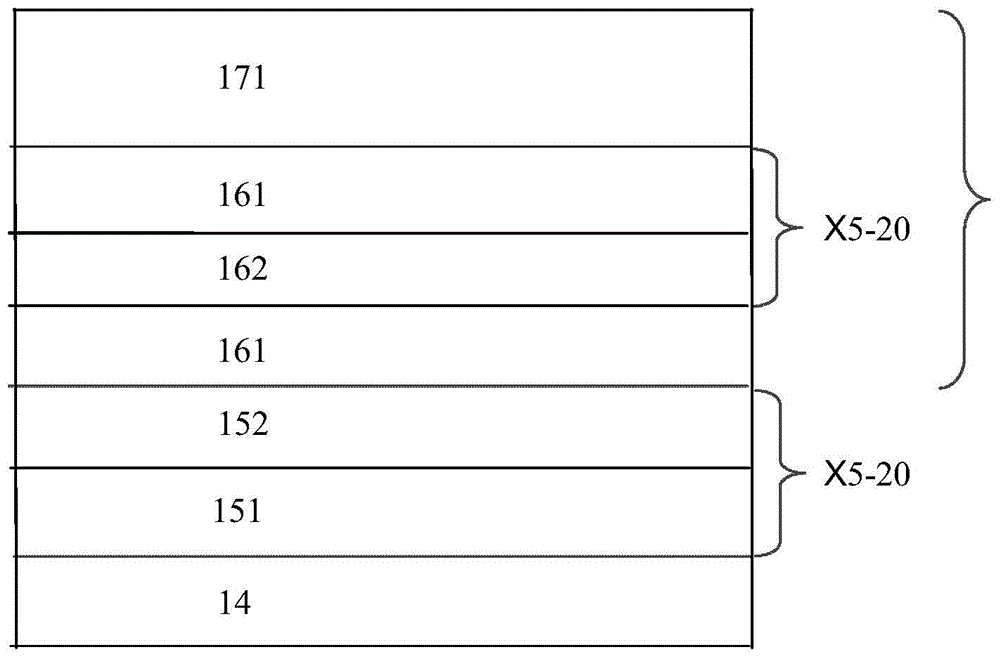

[0040] Please refer to figure 2 , the GaN-based Group III-V compound semiconductor LED epitaxial wafer of the present invention, its structure from bottom to top is: substrate 11, low-temperature GaN buffer layer 12, first high-temperature non-doped GaN layer 13, second high-temperature non-doped GaN layer GaN layer 14, on the second high-temperature non-doped GaN layer 14 is an AlGaN / GaN superlattice layer 15, on the AlGaN / GaN superlattice layer 15 is a high-temperature N-type GaN layer 16, on the On the high-temperature N-type GaN layer 16 is a stress release layer 17, on the stress release layer 17 is an MQW protection layer 18, on the MQW protection layer 18 is a P-type electron blocking layer 19, on the P-type electron blocking layer On the layer 19 is a high-temperature P-type GaN layer 20 , and on the high-temperature P-type GaN layer 20 is a contact layer 21 .

[0041] Preferably, a SiN mask / N-type GaN layer is periodically inserted into the high-temperature N-type G...

Embodiment 2

[0061] The growth method of the GaN-based III-V compound semiconductor LED epitaxial wafer in this embodiment is as follows:

[0062] Place the sapphire substrate in the MOCVD reaction chamber, and use H 2 , NH 3 Wait for the gas to treat the sapphire substrate at high temperature for 4 to 10 minutes.

[0063] After the high-temperature treatment is completed, the temperature of the reaction chamber is lowered to 500-650°C, and TMGa and NH 3 , the pressure is controlled at 300mbar-900mbar, and a low-temperature GaN buffer layer with a thickness of 20-50nm is grown on the sapphire substrate.

[0064] After the low-temperature GaN buffer layer is grown, the temperature is raised to 950-1100° C., and the high-temperature annealing is performed for 60-300 s to form a GaN crystal nucleus on the substrate.

[0065] After the high-temperature annealing is completed, the temperature is adjusted to 950-1050°C, and TMGa and NH 3 , the pressure is controlled at 300mbar-900mbar, and a...

Embodiment 3

[0077] The growth method of the GaN-based III-V compound semiconductor LED epitaxial wafer in this embodiment is as follows:

[0078] Place the sapphire substrate in the MOCVD reaction chamber, and use H 2 , NH 3 Wait for the gas to treat the sapphire substrate at high temperature for 4 to 10 minutes.

[0079] After the high-temperature treatment is completed, the temperature of the reaction chamber is lowered to 500-650°C, and TMGa and NH 3 , the pressure is controlled at 300mbar-900mbar, and a low-temperature GaN buffer layer with a thickness of 20-50nm is grown on the sapphire substrate.

[0080] After the low-temperature GaN buffer layer is grown, the temperature is raised to 950-1100° C., and the high-temperature annealing is performed for 60-300 s to form a GaN crystal nucleus on the substrate.

[0081] After the high-temperature annealing is completed, the temperature is adjusted to 950-1050°C, and TMGa and NH 3 , the pressure is controlled at 300mbar-900mbar, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com