Method for producing graphite material with Acheson graphitization furnace

A graphitization furnace and graphite material technology, applied in chemical instruments and methods, furnaces, furnace bottoms, etc., can solve the problems of low energy utilization rate, increased production cost, high product cost, etc., shorten heating time, reduce heat loss, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples are exemplary and intended to illustrate the technical solutions of the present invention more clearly, but should not be construed as limiting the present invention.

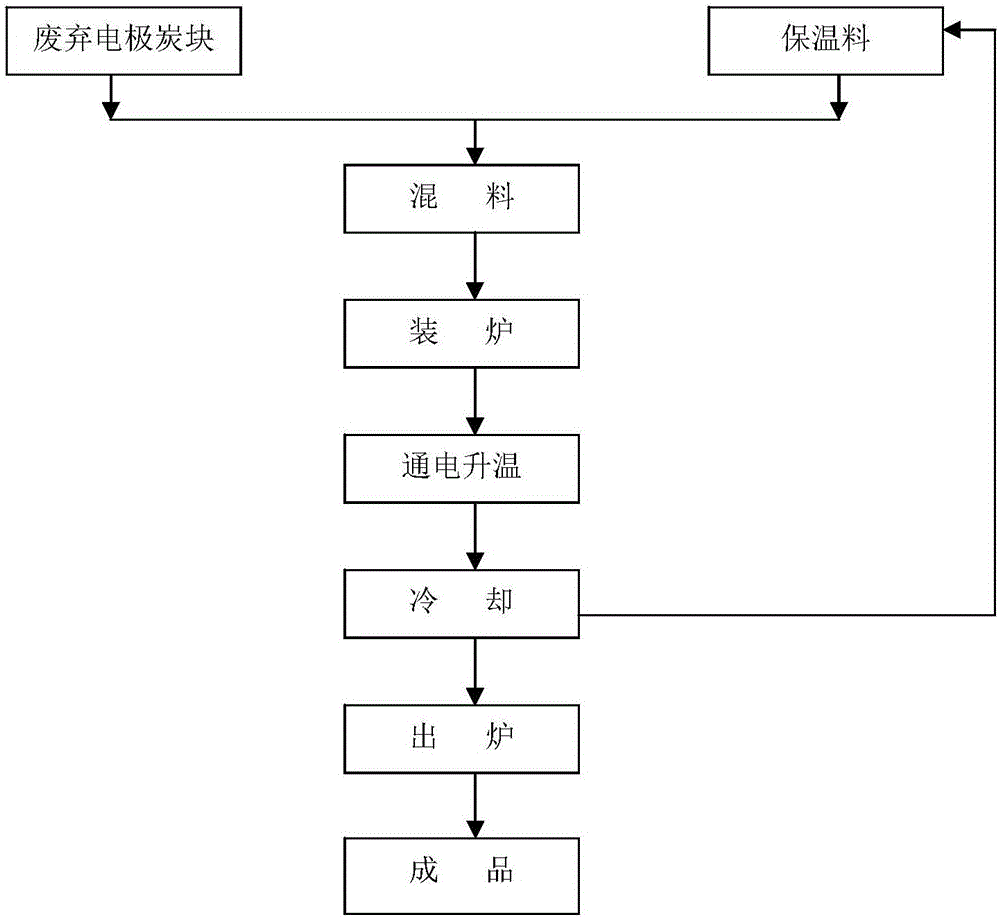

[0020] like figure 1 As shown, the process flow of the method for producing graphite material with the Acheson graphitization furnace provided in this embodiment is as follows:

[0021] First, a layer of insulation material is laid on the bottom of the Acheson graphitization furnace. It needs to be laid flat. The thickness of the formed insulation layer is about 60 cm. The insulation material is made of coke and quartz sand; then the insulation material is placed along the length of the furnace body. Place two baffles in the direction, the distance between the two baffles is about 1 meter, the two baffles are almost parallel, and the center line symmetric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com