Furnace tube device

A furnace tube and ventilation tube technology, applied in the field of semiconductor manufacturing equipment, can solve the problems of long distribution span of wafers and differences in wafer processing effects, etc., and achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

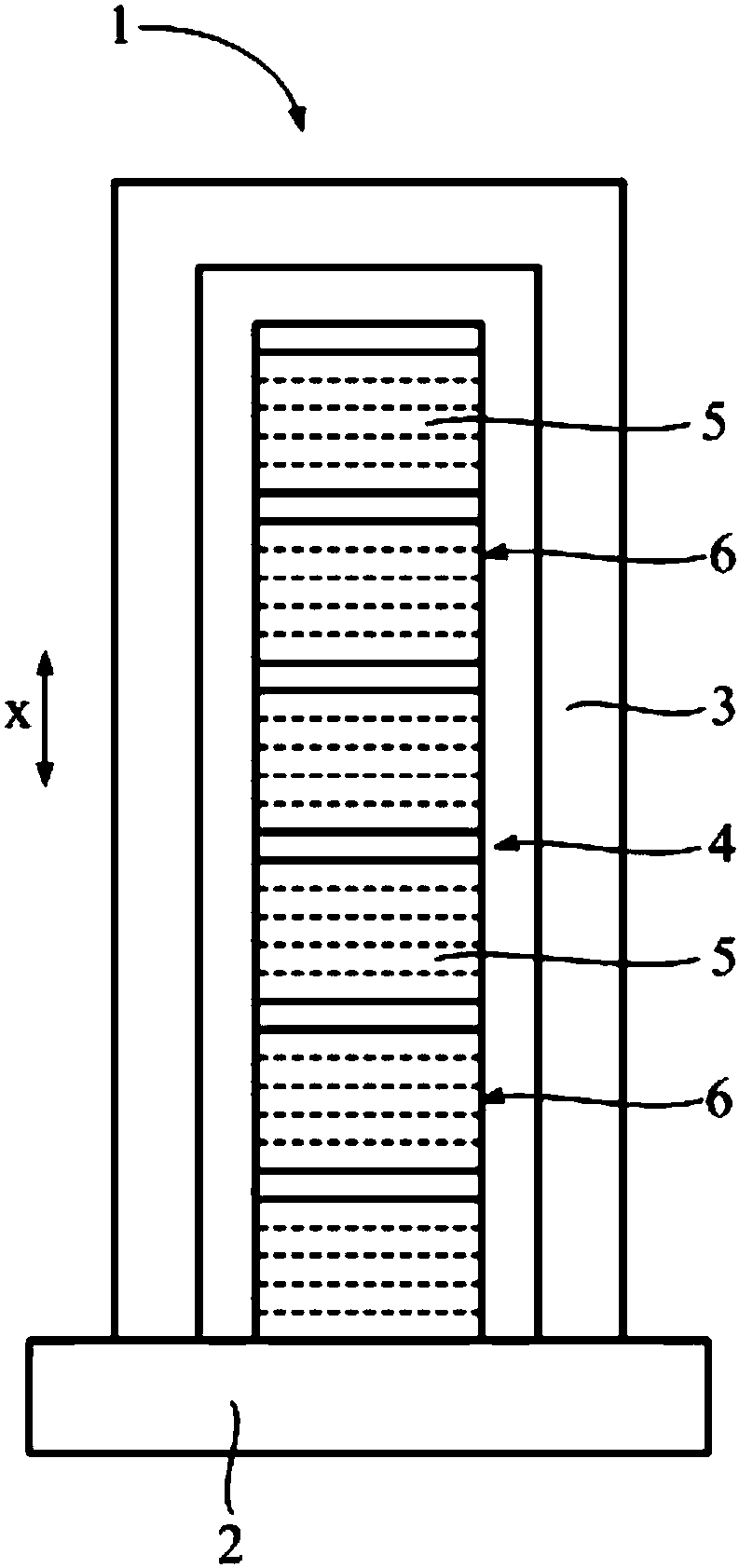

[0023] refer to figure 1 , the furnace tube device 1 in the prior art has a larger height, so that the furnace tube cavity 4 has a longer distance along the height direction x, so that more wafers 5 can be stacked in the height direction, so as to simultaneously Multiple wafers 5 are oxidized, doped or heat-treated.

[0024] In the process of using the furnace tube device 1 to process the wafer 5, for example, when a silicon nitride (SiN) film needs to be deposited on the surface of the wafer 5, dichlorosilane (DCS) and ammonia (NH 3 ) and other process gases are passed into the furnace cavity 4; at the same time, the furnace cavity 4 needs to be heated to heat the wafer 5, and dichlorosilane and ammonia react on the surface of the wafer 5 to form a silicon nitride film.

[0025] However, since the furnace tube cavity 4 has a long distance along the height direction x, the distribution of dichlorosilane and ammonia in the furnace tube cavity 4 will be uneven, and dichlorosila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com