Electric furnace applicable to thermal state experiment of blast-furnace cooling staves with different sizes

A technology of cooling staves and thermal state experiments, applied in the furnace, furnace lining, furnace bottom and other directions, can solve the problems of difficult to control the temperature in the furnace, the overall height of the furnace is high, and the flue gas pollutes the environment, etc. The effect of land area and test operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in conjunction with the accompanying drawings and specific implementation methods, without limiting its protection scope.

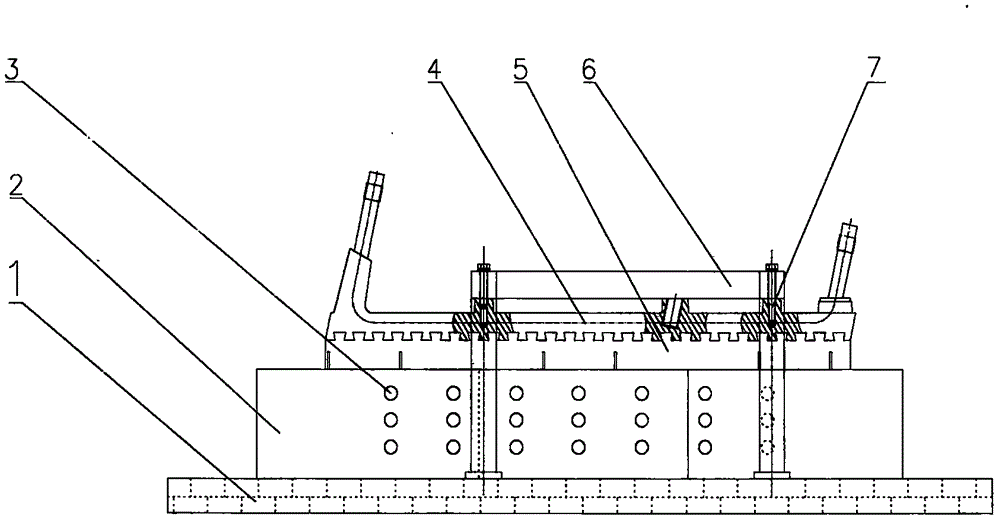

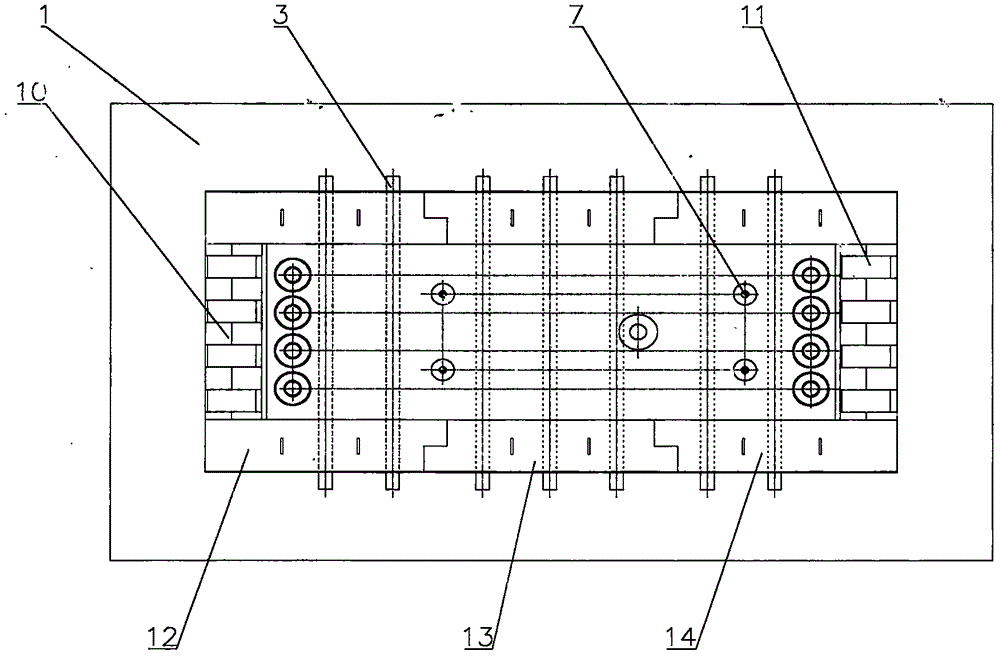

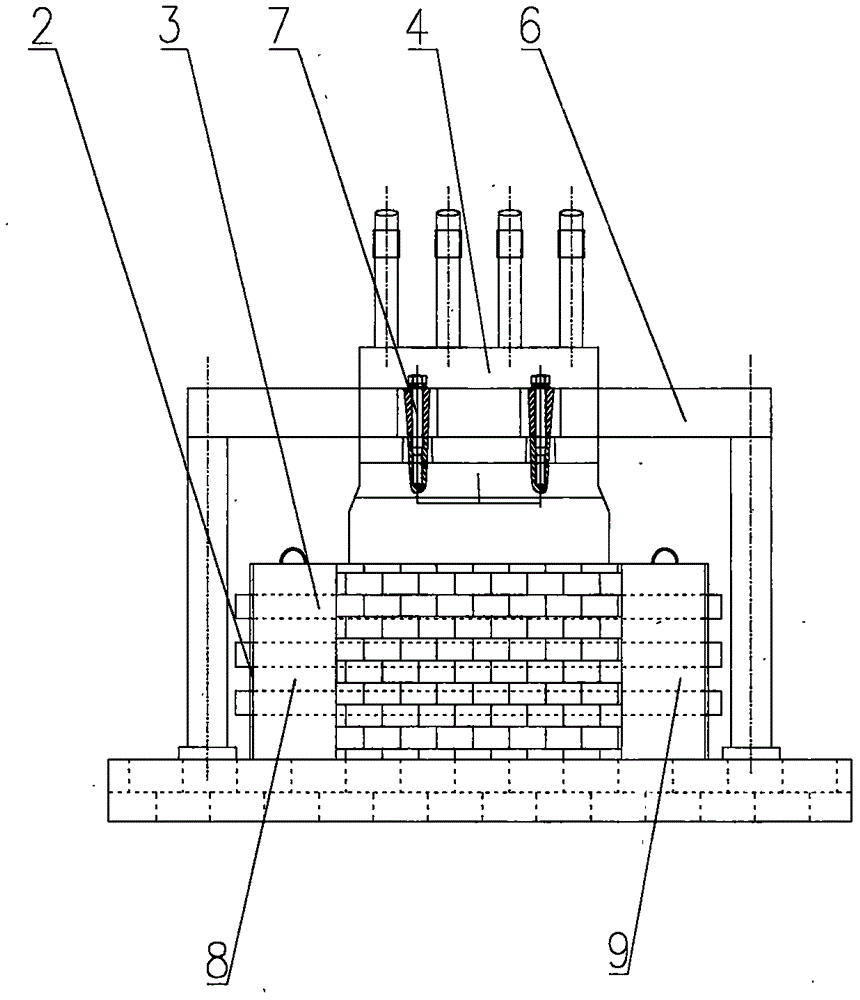

[0016] A blast furnace cooling stave hot-state experimental furnace, which consists of furnace bottom (1), furnace wall (2), heating tube group (3), cooling stave (4), inlaid bricks (5), and supporting frame (6). The bottom (1) is made of refractory bricks laid flat on the ground, and the furnace wall (2) is composed of the front furnace wall (8), the rear furnace wall (9), the left furnace wall (10), and the right furnace wall (11). The combined furnace wall, the front furnace wall (8) and the rear furnace wall (9) are fixed on the furnace bottom (1), and are respectively composed of three pieces of left plate (12), middle plate (13) and right plate (14) It consists of prefabricated panels, wherein the middle panel (13) is a convex-shaped panel and has multiple spare panels of different lengths, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com