Fireproof ceramic bottom

A technology of refractory ceramics and bases, applied in the field of refractory ceramics bases, can solve the problems of complex and expensive refractory linings, achieve the effects of simple laying, increased service time, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

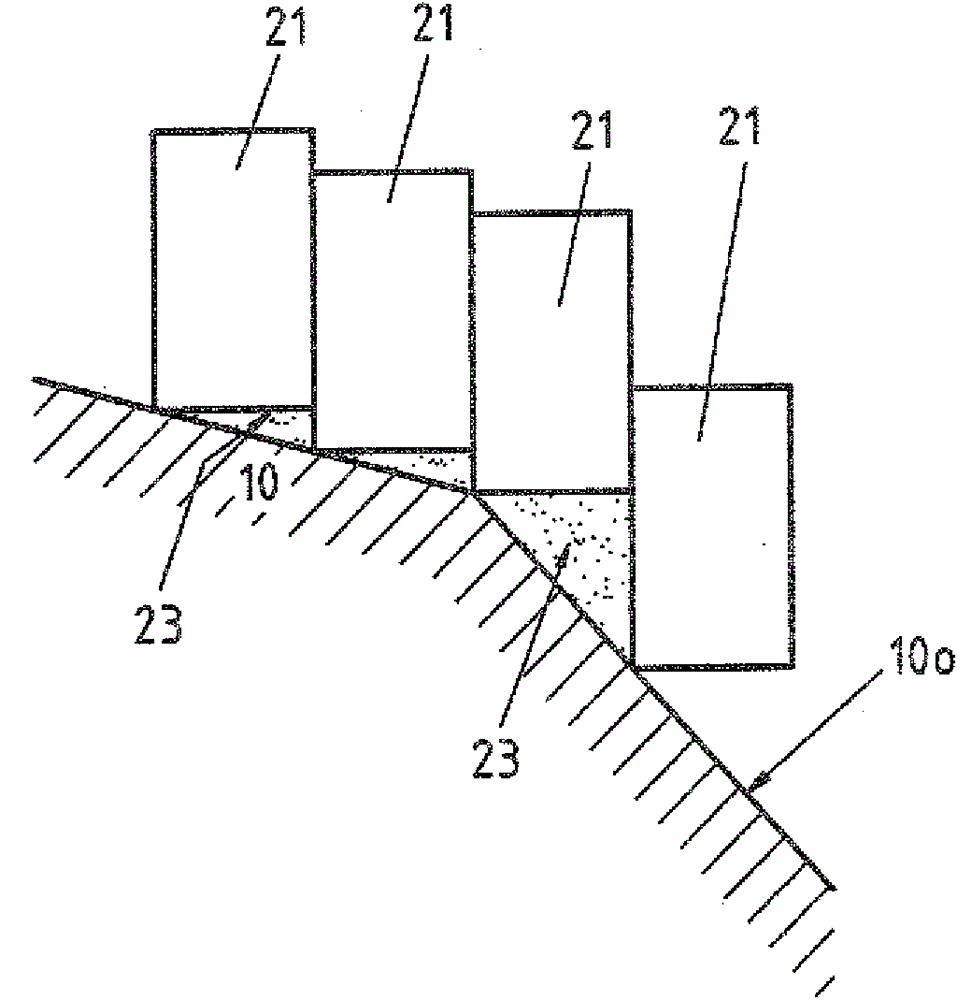

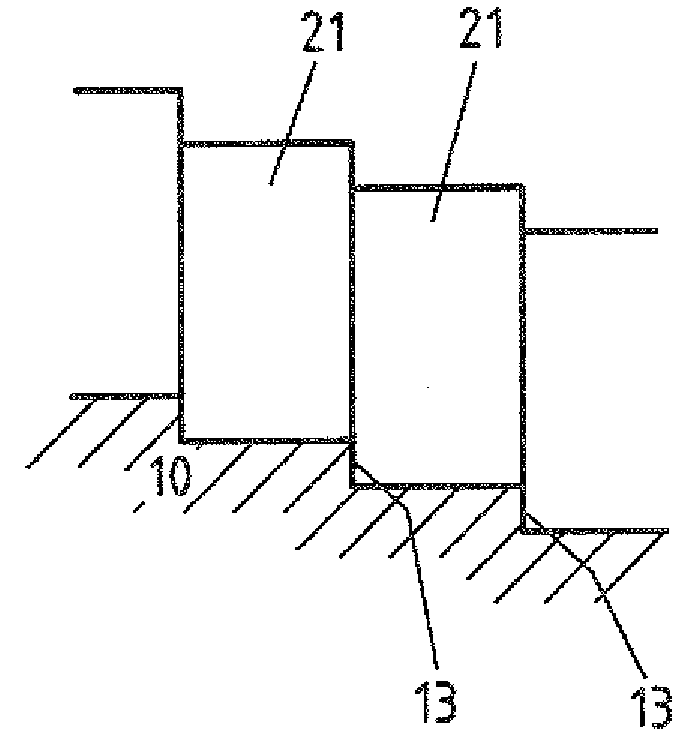

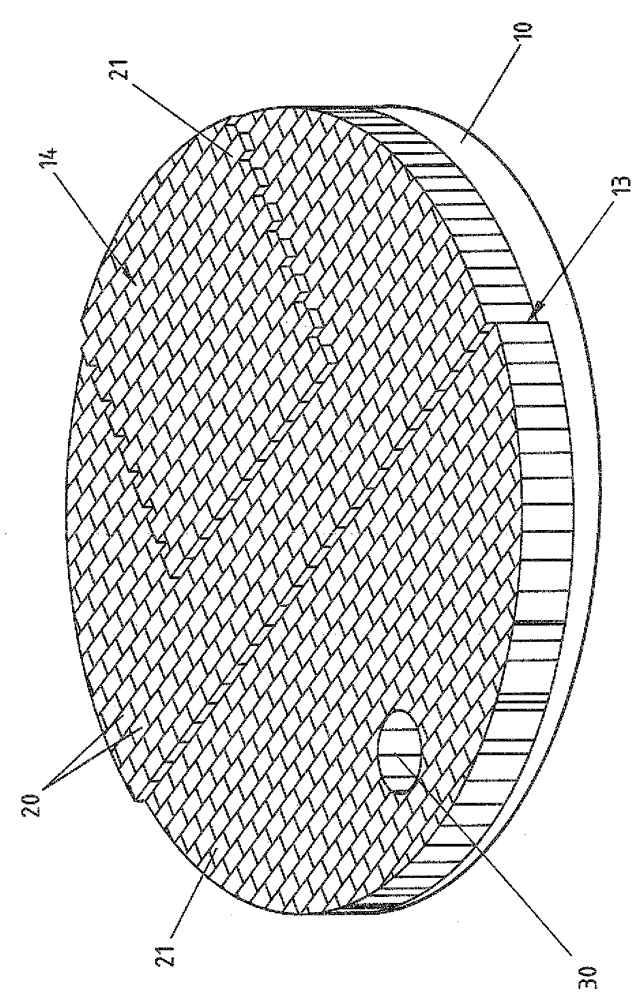

[0078] Figure 1 shows a base with two layers, namely a lower layer 10 and an upper layer 20 arranged on top. Both of them are approximately circular in top view (plan view).

[0079] The lower layer 10 is designed as a permanent lining and is made of a refractory ceramic mass based on alumina. The permanent lining 10 is entirely designed as a prefabricated element and features a horizontal lower surface 10u and a three-dimensionally designed upper surface 10o. Surface 10o is characterized by the following regions:

[0080] - about the first rung 13 in the center;

[0081] - raised impact pad 14 in the upper left third;

[0082] All areas of the surface 10 o are inclined at approximately 3° relative to the horizontal, with a slope in the direction towards the discharge area 30 .

[0083] The upper layer 20 , so the wear layer, consists mainly of (>80M.-%) cubic refractory bricks 21 of the same size and uniform layout (except in the area of the discharge opening 30 ).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com