A high water-reducing and high-early-strength polycarboxylate water-reducing agent and its non-pyrogenic preparation method

A polycarboxylate-based, high-early-strength technology, applied in the field of concrete admixtures, can solve the problems of unstable quality, complex production process of water reducing agent, high energy consumption in production, etc., to improve the quality of construction projects and solve the problem of setting time Long-term, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

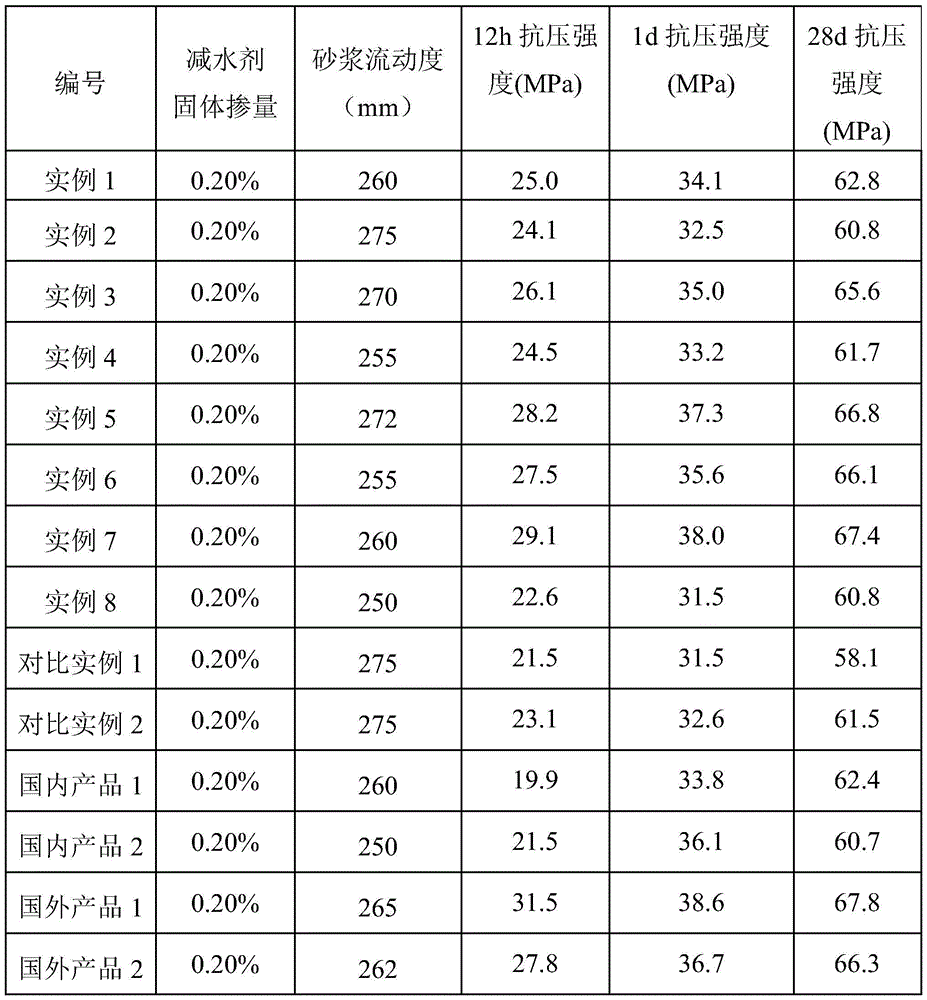

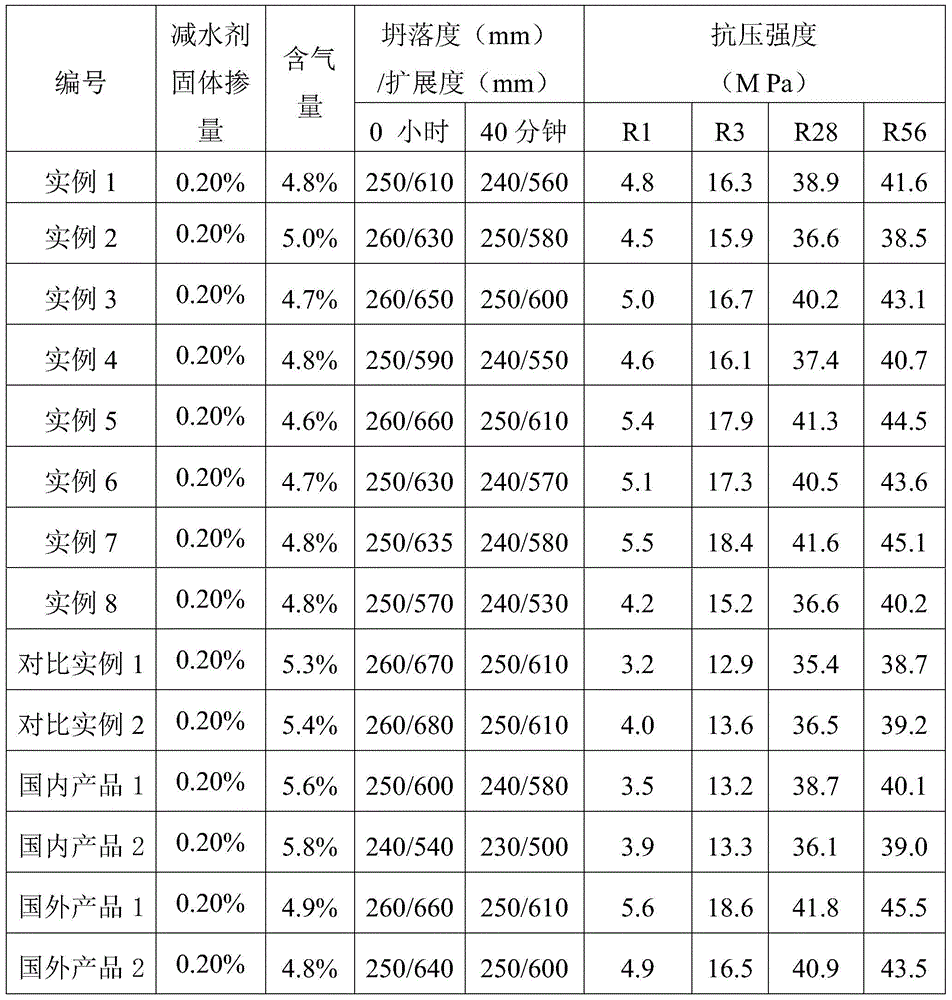

Examples

Embodiment 1

[0047] Prepare high water-reducing and high-slump retention type polycarboxylate high-performance water-reducing agent according to the following raw material quantity and process, specifically:

[0048] (1) Preparation of early-strength polycarboxylate superplasticizer mother liquor T-1

[0049] ①Material preparation: Add 0.20g of L-ascorbic acid into 13g of deionized water, mix evenly, and use tank A for spare, which is material A; 12.0g of acrylic acid, 5.0g of acrylamide, 2.16g of sodium methacrylate, add into 40g of deionized water , mixed evenly, and the B tank is reserved, which is the b material;

[0050] ②Polymerization: Add 289.5g of deionized water and 210g of unsaturated polyoxyethylene ether (MW=4000) into a glass reactor equipped with a thermometer and an electric stirrer, stir and dissolve fully, then add H 2 o 2 1.45g, stir evenly, keep the temperature at 15°C, add material a and material b dropwise at the same time, control the polymerization temperature at ...

Embodiment 2

[0054] Prepare high water-reducing and high-slump retention type polycarboxylate high-performance water-reducing agent according to the following raw material quantity and process, specifically:

[0055] (1) Preparation of early-strength polycarboxylate superplasticizer mother liquor T-2

[0056] ①Material preparation: Add 0.35g of L-ascorbic acid into 13g of deionized water, mix evenly, reserve tank A as material A; add 16.0g of acrylic acid, 6.0g of acrylamide, and 0.45g of 3-mercaptopropionic acid into 40g of deionized water, Mix evenly, and reserve the B tank, which is the b material;

[0057] ②Polymerization: Add 187.3g of deionized water and 140g of unsaturated polyoxyethylene ether (MW=4000) into a glass reactor equipped with a thermometer and an electric stirrer, stir and dissolve fully, then add H 2 o 2 0.57g, stir evenly, keep the temperature at 18°C, add material a and material b dropwise at the same time, control the polymerization temperature at 15-40°C, add mat...

Embodiment 3

[0061] Prepare high water-reducing and high-slump retention type polycarboxylate high-performance water-reducing agent according to the following raw material quantity and process, specifically:

[0062] (1) Preparation of early-strength polycarboxylate superplasticizer mother liquor T-3

[0063] ①Material preparation: Add 0.21g of L-ascorbic acid into 13g of deionized water, mix evenly, reserve tank A as material A; add 12.0g of acrylic acid, 5.0g of acrylamide, 2.28g of sodium methacrylate into 40g of deionized water, Mix evenly, and reserve the B tank, which is the b material;

[0064] ②Polymerization: Add 228.7g of deionized water and 170g of unsaturated polyoxyethylene ether (MW=3800) into a glass reactor equipped with a thermometer and an electric stirrer, stir and dissolve fully, then add H 2 o 2 0.57g, stir evenly, keep the temperature at 27°C, add material a and material b dropwise at the same time, control the polymerization temperature at 15-40°C, add material a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com