Protection drilling fluid for low-pressure reservoir

A technology for reservoir protection and oil layer protection, which is applied in the field of drilling fluid, can solve the problems of ineffective prevention of formation hydration expansion, poor plugging effect, and ineffective control of drilling hydraulic pressure loss, so as to protect wellbore conditions and prevent Effect of migration and prevention of hydration expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

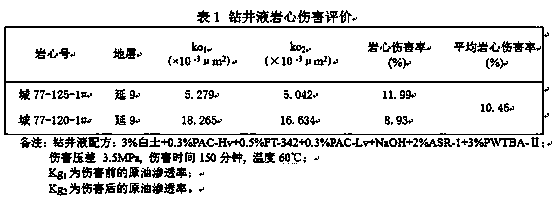

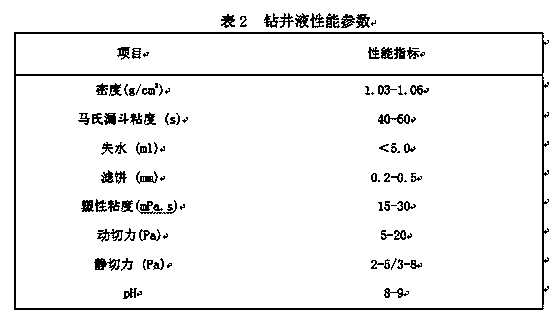

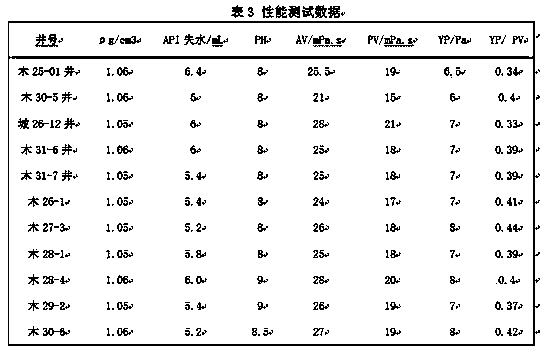

[0021] The following components are used to prepare the drilling fluid for protecting reservoirs in low-pressure reservoirs above Chang 8 in Longdong Oilfield. According to the weight percentage, the weight ratio of clean water is 90.7%, the weight ratio of polyanionic cellulose (high viscosity) is 0.3%, and the weight ratio of sulfonated asphalt is 0.5%, add polyanionic cellulose (low viscosity) by weight 0.3%, add caustic soda by weight 0.2%, add hydroxypropyl starch by weight 2%, oil layer protective agent by weight 3%, white clay by weight 3%. Formation protection reservoir drilling fluid.

[0022] Polyanionic Cellulose (PAC)

[0023] PAC, divided into high viscosity (HV) and low viscosity (LV), can be used as thickener, rheology control agent, adhesive, stabilizer, protective colloid, suspending agent and water retaining agent; in the oil exploration industry Among them, PAC is a better drilling mud treatment agent and material for preparing completion fluid, with high m...

Embodiment 2

[0048] The following components are used to prepare the drilling fluid for protection of low-pressure oil reservoirs. According to the weight percentage, the weight ratio of clean water is 91.5%, the weight ratio of polyanionic cellulose (high viscosity) is 0.1%, the weight ratio of sulfonated bitumen is 0.5%, and the weight ratio of polyanionic fiber is added. The weight ratio of plain (low viscosity) is 0.2%, the weight ratio of caustic soda is 0.2%, the weight ratio of hydroxypropyl starch is 2.0%, the weight ratio of refueling layer protection agent is 2.5%, and the weight ratio of clay is 3%. drilling fluid.

Embodiment 3

[0050] The following components are used to prepare the drilling fluid for protection of low-pressure oil reservoirs. According to the weight percentage, the weight ratio of clean water is 91.2%, the weight ratio of polyanionic cellulose (high viscosity) is 0.3%, the weight ratio of sulfonated bitumen is 0.5%, and the weight ratio of polyanionic fiber is added. The weight ratio of plain (low viscosity) is 0.3%, the weight ratio of caustic soda is 0.2%, the weight ratio of hydroxypropyl starch is 1.5%, the weight ratio of refueling layer protection agent is 3.0%, and the weight ratio of white clay is 3%. drilling fluid.

[0051] In the application of Examples 2 and 3, the system also shows the effect of reducing water loss, good plugging effect and lubrication and drag reduction effect, the wellbore is stable during the drilling process, and the casing is smoothly run into the bottom of the well during the completion process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com