Chemical plugging remover suitable for ternary composite flooding injection well

A technology of ternary compounding and deblocking agent, applied in chemical instruments and methods, composition of drilling holes, etc., can solve problems such as poor effect of deblocking agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Weigh 10g of polymer degradation agent and 90g of water to prepare the precursor; weigh 7g of hydrochloric acid, 3g of glacial acetic acid, 3g of ammonium fluoride, 1.0g of triethanolamine, 0.5g of imidazoline quaternary ammonium corrosion inhibitor and 85.5g of water to prepare Main agent: weigh 1.0 g of hydroxyethylidene diphosphonic acid, 0.5 g of hexamethylenetetraammonium and 98.5 g of water to prepare the post agent.

Embodiment 2

[0014] Weigh 15g of polymer degradation agent and 85g of water to prepare the precursor; weigh 10g of hydrochloric acid, 5g of glacial acetic acid, 5g of ammonium fluoride, 2.0g of triethanolamine, 1.0g of imidazoline quaternary ammonium corrosion inhibitor and 77.0g of water to prepare Main agent: weigh 3.0 g of hydroxyethylidene diphosphonic acid, 1.0 g of hexamethylenetetraammonium and 96.0 g of water to prepare the latter agent.

Embodiment 3

[0016] Weigh 12g of polymer degradation agent and 88g of water to prepare the precursor; weigh 8g of hydrochloric acid, 4g of glacial acetic acid, 4g of ammonium fluoride, 1.5g of triethanolamine, 1.0g of imidazoline quaternary ammonium corrosion inhibitor and 81.5g of water to prepare Main agent: weigh 2.0g of hydroxyethylidene diphosphonic acid, 1.0g of hexamethylenetetraammonium and 97.0g of water to prepare the latter agent.

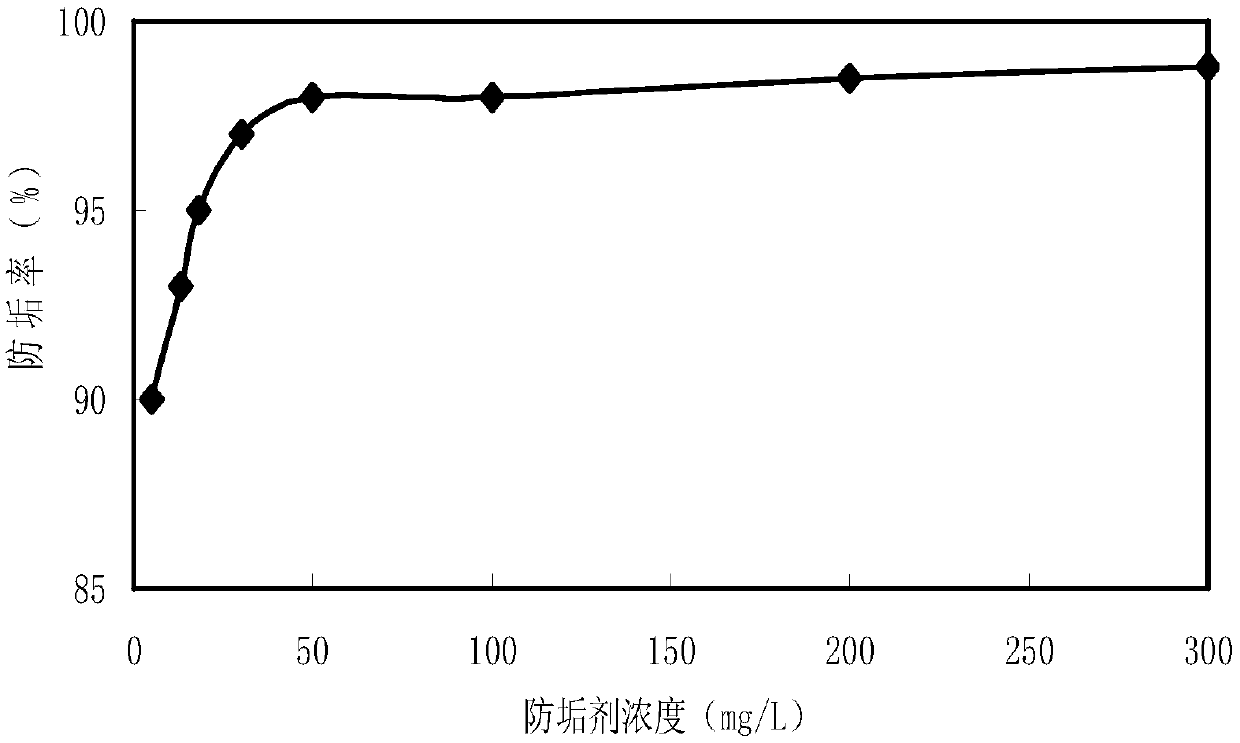

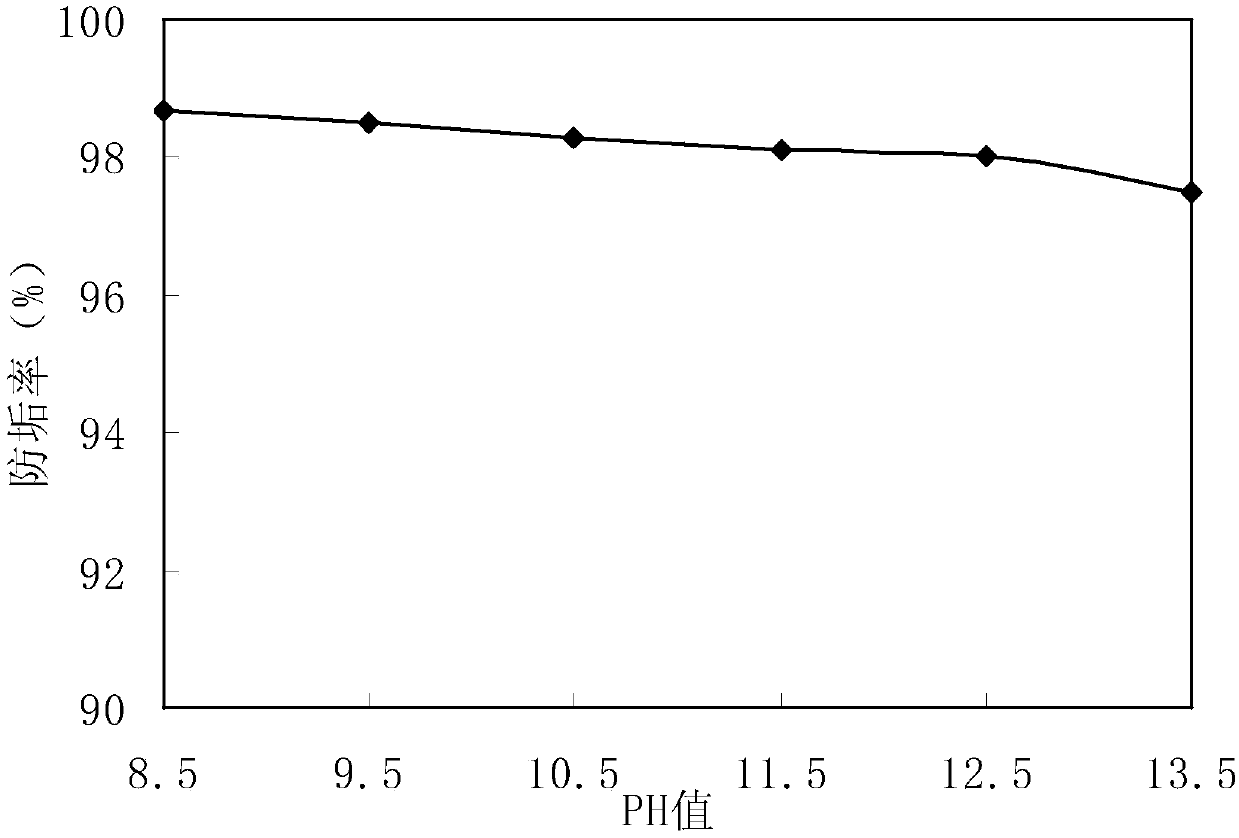

[0017] This is suitable for performance evaluation of chemical plugging agent for ASP flooding injection wells:

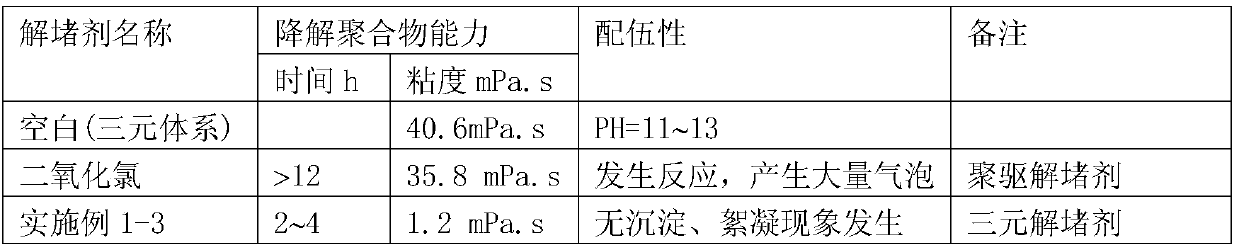

[0018] 1. Polymer degradation performance

[0019] The working system of the chlorine dioxide chemical plugging agent used in polymer flooding is acidic, has poor compatibility with the ternary system, and has weak degradation ability to polymers in the ternary system; Good viscosity-reducing effect, good compatibility with the ternary system, fast degradation speed, the viscosity of the ternary system can be reduced to the viscosity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com