A high-performance structural reinforcement mortar composition and its preparation process

A high-performance, composite technology, applied in the field of building materials, can solve problems such as improper use and maintenance, safety hazards, etc., and achieve the effects of convenient transportation and use, stable performance, and excellent sulfate corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

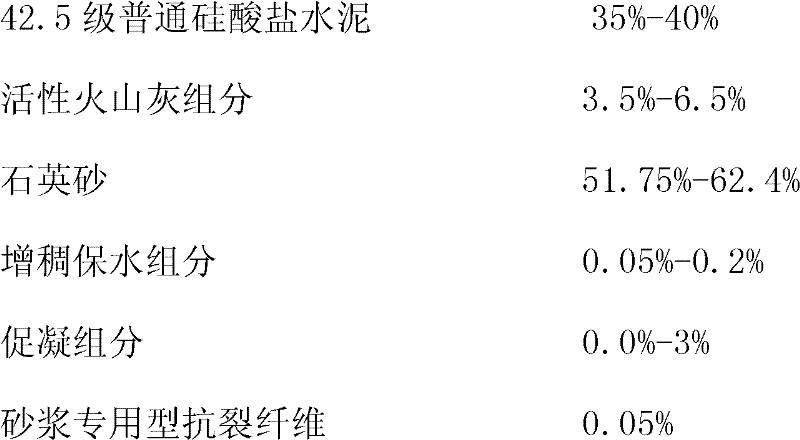

[0025] The distribution ratio of each component of high-performance structural reinforcement mortar is as follows (winter construction):

[0026]

[0027] Performance indicators of polymer mortar for concrete structure reinforcement:

[0028]

[0029]

[0030] The preparation process of the high-performance structural reinforcement mortar composition of the above ratio, its specific steps are as follows:

[0031] (1) First, the active pozzolan component and each mortar-specific admixture are pre-mixed in proportion;

[0032] (2) Then, the uniformly stirred mixture, 42.5-grade ordinary Portland cement and quartz sand are weighed in proportion, mixed, stirred evenly, and packaged to obtain the high-performance structural reinforcement mortar composition referred to in the present invention.

Embodiment 2

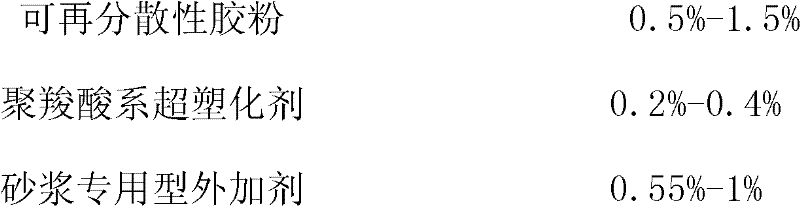

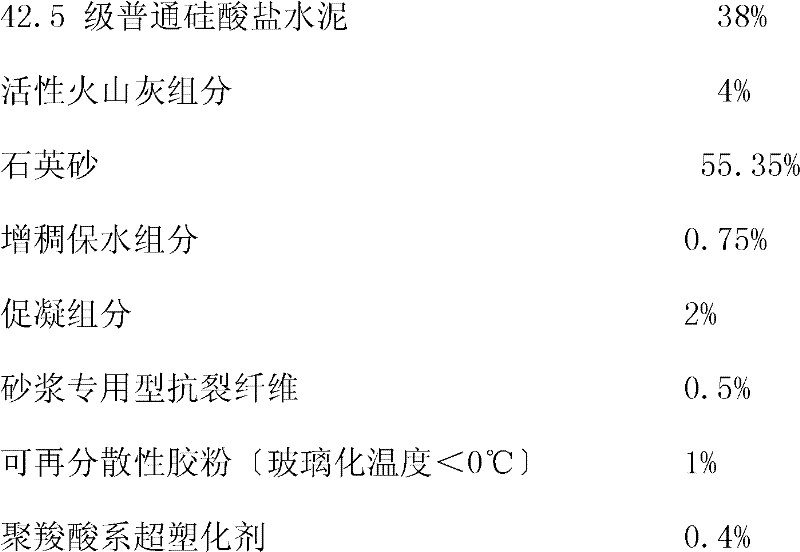

[0034] The proportion of each component of polymer mortar for concrete structure reinforcement is as follows (summer construction):

[0035]

[0036] Performance indicators of polymer mortar for concrete structure reinforcement:

[0037]

[0038] The preparation process of the high-performance structure-reinforced mortar composition with the above proportions includes the following steps: directly weighing, mixing, uniformly stirring and packaging each component in proportion to obtain the high-performance structure-reinforced mortar composition referred to in the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com