High-performance expanded hybrid fiber concrete material for wet joints, and preparation method thereof

A hybrid fiber and concrete technology, which is applied in the field of high-performance expanded hybrid fiber reinforced concrete materials and its preparation, can solve the problems of increased strain, fatigue failure, and reduced beam stiffness of beam concrete, ordinary steel bars and prestressed steel bars, etc. Add simple and convenient, improve fatigue resistance, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

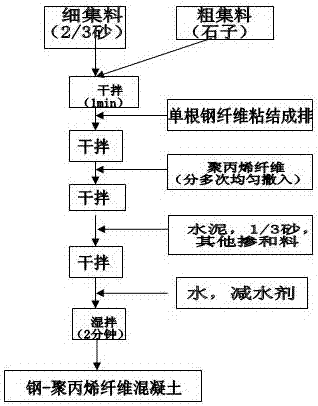

Method used

Image

Examples

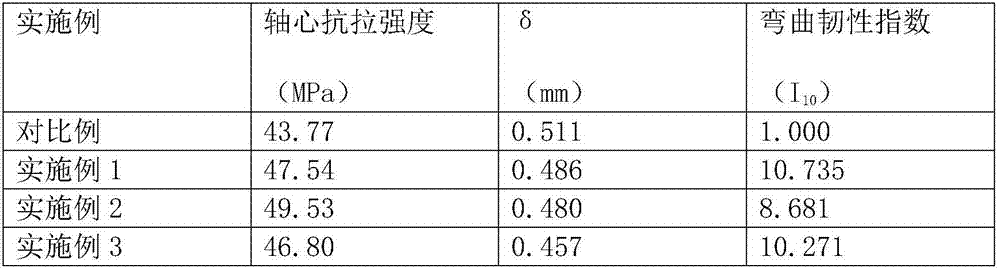

Embodiment 1

[0036] A new type of high-strength hybrid fiber concrete wet joint material for simply supported and then continuous girder bridges, which is made by mixing the following raw materials in parts by weight: 11.25 kg of cement, 1.125 kg of fly ash, 0.625 kg of silica fume, 26.625 kg of stone, Sand 16.5 kg, water 4.375 kg, water reducer (Kao) 0.09 kg, steel fiber 1.26 kg, polypropylene fiber 0.025 kg. The cement is Huangshihua brand 52.5 Portland cement; the fly ash is Class I fly ash with a specific surface area of 4800cm 2 / g; the silica fume is silica fume; the stone is crushed stone, small stone 5mm-10mm, large stone 10mm-20mm, the ratio of large stone to small stone is 55%, 45%; the sand is machine-made sand, The fineness modulus is 2.7, the mud content is ≤1.4%, the stone powder content is 8.3%, and the gradation is continuous and good; the water mentioned is clean tap water; the water reducer is JM-Ⅱ coagulation high-efficiency water reducer, The water reducing rate is 2...

Embodiment 2

[0043] A new type of high-strength hybrid fiber concrete wet joint material for simply supported and then continuous girder bridges, which is made by mixing the following raw materials in parts by weight: 11.25 kg of cement, 1.125 kg of fly ash, 0.625 kg of silica fume, 26.625 kg of stone, 16.5 kg of sand, 4.375 kg of water, 0.09 kg of water reducing agent (Kao), 1.15 kg of steel fiber, and 0.030 kg of polypropylene fiber. The cement is Huangshihua brand 52.5 Portland cement; the fly ash is Class I fly ash with a specific surface area of 4800cm 2 / g; the silica fume is silica fume; the stone is crushed stone, small stone 5mm-10mm, large stone 10mm-20mm, the ratio of large stone to small stone is 55%, 45%; the sand is machine-made sand, The fineness modulus is 2.7, the mud content is ≤1.4%, the stone powder content is 8.3%, and the gradation is continuous and good; the water mentioned is clean tap water; the water reducer is JM-Ⅱ coagulation high-efficiency water reducer, Th...

Embodiment 3

[0050] A new type of high-strength hybrid fiber concrete wet joint material for simply supported and then continuous girder bridges, which is made by mixing the following raw materials in parts by weight: 11.25 kg of cement, 1.125 kg of fly ash, 0.625 kg of silica fume, 26.625 kg of stone, 16.5 kg of sand, 4.375 kg of water, 0.09 kg of water reducing agent (Kao), 1.10 kg of steel fiber, and 0.040 kg of polypropylene fiber. The cement is Huangshihua brand 52.5 Portland cement; the fly ash is Class I fly ash with a specific surface area of 4800cm 2 / g; the silica fume is silica fume; the stone is crushed stone, small stone 5mm-10mm, large stone 10mm-20mm, the ratio of large stone to small stone is 55%, 45%; the sand is machine-made sand, The fineness modulus is 2.7, the mud content is ≤1.4%, the stone powder content is 8.3%, and the gradation is continuous and good; the water mentioned is clean tap water; the water reducer is JM-Ⅱ coagulation high-efficiency water reducer, Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com