Preparation method for flame-retardant heatproof corrosion-resistant adhesive

An adhesive and flame-retardant technology, which is applied in the field of preparation of flame-retardant heat-resistant and corrosion-resistant adhesives, can solve problems such as the complex operating environment of chimneys and threats to the personal safety of engineering and construction personnel, so as to improve the competitiveness of enterprises and cured products. Good adhesion and high and low temperature alternating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

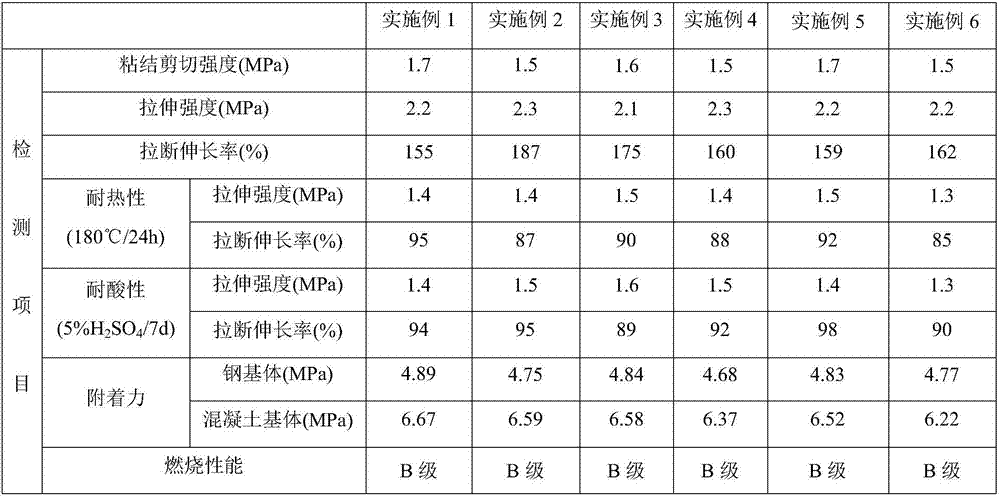

Examples

Embodiment 1

[0024] The preparation process of the flame-retardant temperature-resistant and corrosion-resistant adhesive in this embodiment is as follows:

[0025] 1) Preparation of component A: 100 parts by mass of 107 glue, 3 parts by mass of dimethyl silicone oil and 10 parts by mass of flame-retardant polyether polyol, 3 parts by mass of KH-550 and 15 parts by mass of solvent ( A mixture of toluene and acetone with a volume ratio of 5:1) was added to the reactor, the temperature was raised to 90°C under agitation, and stirring was continued for 10 minutes, and then 50 parts by mass of calcium sulfate whiskers and the coupled gas-phase white carbon black were added The mixture (the mass ratio is 4:1), stir evenly, add 5 parts by mass of TCPP, continue to stir at constant temperature for 60 minutes, cool and filter to obtain the A component of the adhesive.

[0026] 2) Preparation of component B: mix ethylene glycol monoethyl ether semi-closed diphenylmethane diisocyanate, dibutyltin dilaura...

Embodiment 2

[0031] 1) Preparation of component A: 100 parts by mass of 107 glue, 3.5 parts by mass of dimethyl silicone oil, 12 parts by mass of flame-retardant polyether polyol, 2.5 parts by mass of KH-550 and 15 parts by mass of solvent ( A mixture of toluene and acetone with a volume ratio of 5:1) was added to the reactor, the temperature was raised to 80°C under stirring, and the stirring was continued for 10 minutes, and then 50 parts by mass of calcium sulfate whiskers and the coupled gas-phase white carbon black were added The mixture (the mass ratio is 4:1), stir evenly, add 4 parts by mass of TCEP, continue to stir at constant temperature for 60 minutes, cool and filter to obtain the A component of the adhesive.

[0032] 2) Preparation of component B: mix ethylene glycol monoethyl ether semi-closed diphenylmethane diisocyanate, dibutyltin dilaurate and solvent at a mass ratio of 1.5:0.5:10, mix and stir evenly at room temperature to obtain the adhesive The B component.

[0033] Where...

Embodiment 3

[0037] 1) Preparation of component A: 100 parts by mass of 107 glue, 4 parts by mass of dimethyl silicone oil, 14 parts by mass of flame-retardant polyether polyol, 3 parts by mass of KH-550 and 20 parts by mass of solvent ( A mixture of toluene and acetone with a volume ratio of 5:1) was added to the reactor, the temperature was raised to 85°C under stirring, and stirring was continued for 10 minutes, and then 40 parts by mass of calcium sulfate whiskers and coupled-treated gas phase silica were added. The mixture (the mass ratio is 4:1), stir evenly, add 5 parts by mass of TDCP, continue to stir at constant temperature for 60 minutes, cool and filter to obtain the A component of the adhesive.

[0038] 2) Preparation of component B: mix ethylene glycol monoethyl ether semi-closed diphenylmethane diisocyanate, dibutyltin diacetate and solvent at a mass ratio of 2.0:0.5:10, mix and stir evenly at room temperature to obtain the adhesive B component.

[0039] Wherein, the solvent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com