Weak consolidation large pore channel treatment system as well as preparation method and application thereof

A technology with large pores and solidity, which is used in solid waste management, chemical instruments and methods, and production of fluids. , the effect of high blocking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

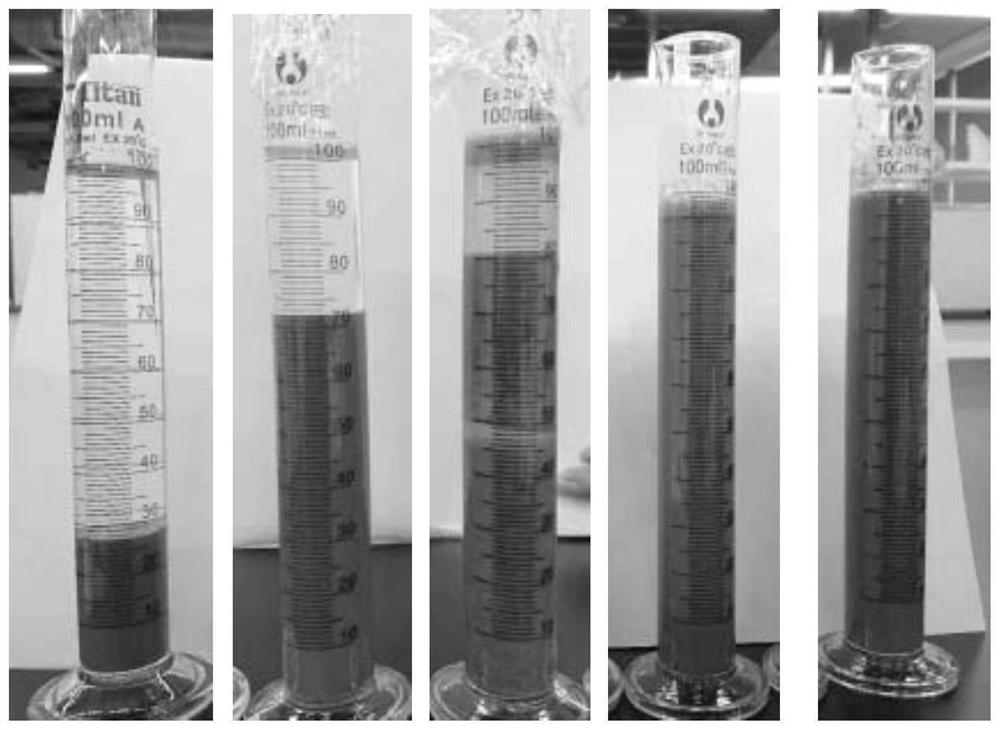

[0071] Example 1. Stability experiment of weakly consolidated large pore channel governance system

[0072] Prepare several groups of systems to observe the stability, and use the sedimentation rate index to measure, the sedimentation rate = the sedimentation volume of the lower layer system / the volume of the upper layer water phase × 100%, the greater the sedimentation rate, the better the stability.

[0073] Sample 1: Add 10% curing agent to the mineralized water of the simulated oilfield formation, evenly disperse it, stir for 10 minutes, and pour it into a 100mL graduated cylinder;

[0074] Sample 2: Add 10% curing agent to the mineralized water of the simulated oilfield formation uniformly, stir for 10 minutes, and then add 0.15% tackifier and 0.8% support strengthening agent in sequence, add while stirring and continue stirring for 60 minutes. Pour into a 100mL graduated cylinder;

[0075] Sample 3#: Add 2% proppant to the mineralized water of the simulated oilfield f...

Embodiment 2

[0081] Embodiment 2, the preparation method of weakly consolidated large pore channel governance system

[0082] Sample 6#: Add 2% proppant to the mineralized water of the simulated oilfield formation uniformly, stir for 10 minutes, and then add 0.25% tackifier, 0.8% propping enhancer, and 6% curing agent in sequence, and add and mix while stirring. After stirring continuously for 60 minutes, pour into a 100mL graduated cylinder;

[0083] Sample 7#: Add 2% proppant to the mineralized water of the simulated oilfield formation uniformly, stir for 10 minutes, and then add 6% curing agent, 0.25% tackifier and 0.8% proppant enhancer in a uniform dispersion, add and stir while stirring. After stirring continuously for 60 minutes, pour into a 100 mL graduated cylinder.

[0084] The sedimentation data of the above samples are shown in Table 2 below.

[0085] Table 2 Settlement data table of different preparation sequence systems

[0086]

Embodiment 3

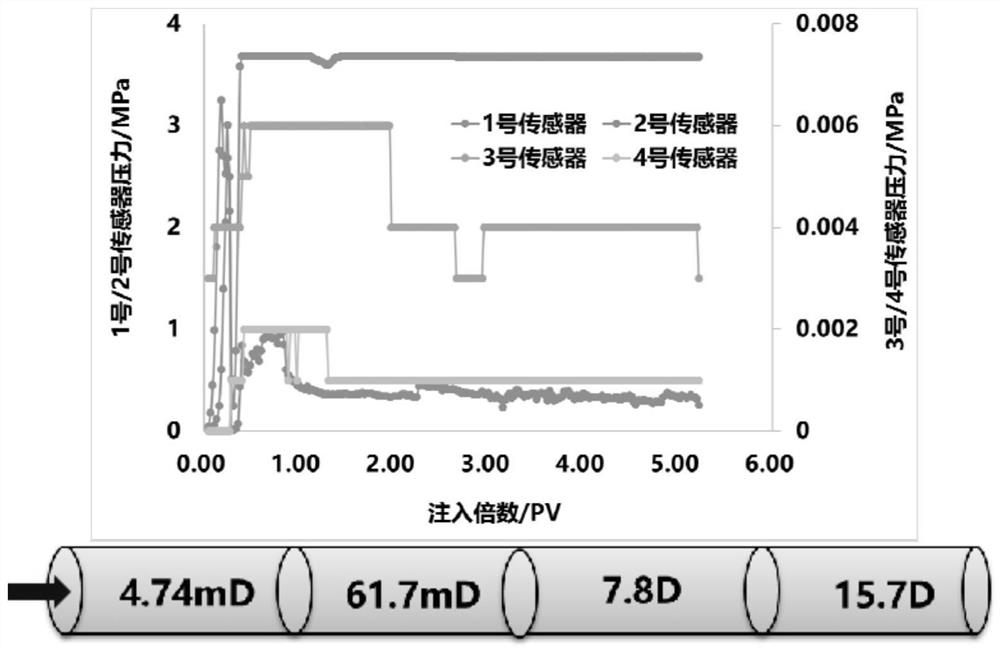

[0087] Example 3. The shape of the weakly consolidated large pore channel governance system

[0088] (1) Add 3% proppant to the mineralized water of the simulated oilfield formation by uniform dispersion, stir for 10 minutes, and then uniformly disperse and add 0.25% tackifier, 0.8% propping enhancer, and 10% curing agent successively, and continue to stir for 60 minutes;

[0089] (2) Take the prepared system in the above (1), put it in a beaker and let it stand for 72 hours, then take it out. See figure 2 ;

[0090] (3) Take the system configured in the above (1), inject it into the sand filling pipe (permeability 168 Darcy, diameter 2.5cm, length 100cm, 4 pressure measuring points), inject 1.8PV followed by water flooding, the production curve and See the schematic diagram of the permeability after plugging image 3 ;

[0091] (4) Take out the sand after the sand filling pipe is left standing for 72 hours, see Figure 4 ;

[0092] (5) After placing the sand taken out i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com