Acrylamide polymer-oil base compounded system and application thereof as cement paste supporting liquid

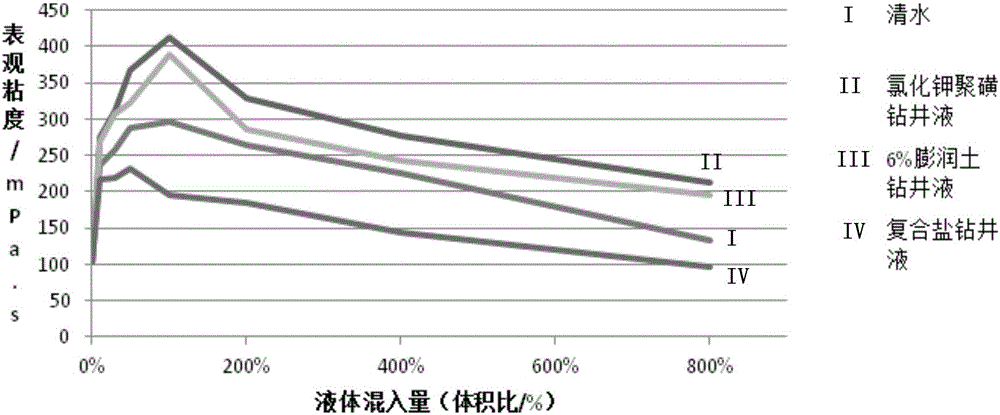

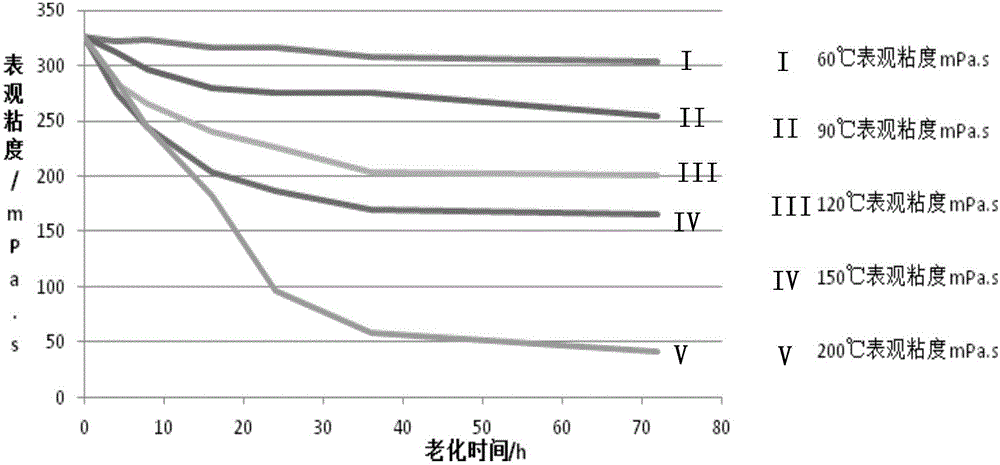

A technology of acrylamide and polymer, which is applied in the field of cement slurry bearing liquid, acrylamide polymer and oil-based compound system, which can solve the problems of cement slurry that cannot reach the support plugging, leakage of large cracks, and plugging failure And other problems, to meet the site construction requirements, strong anti-dilution, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

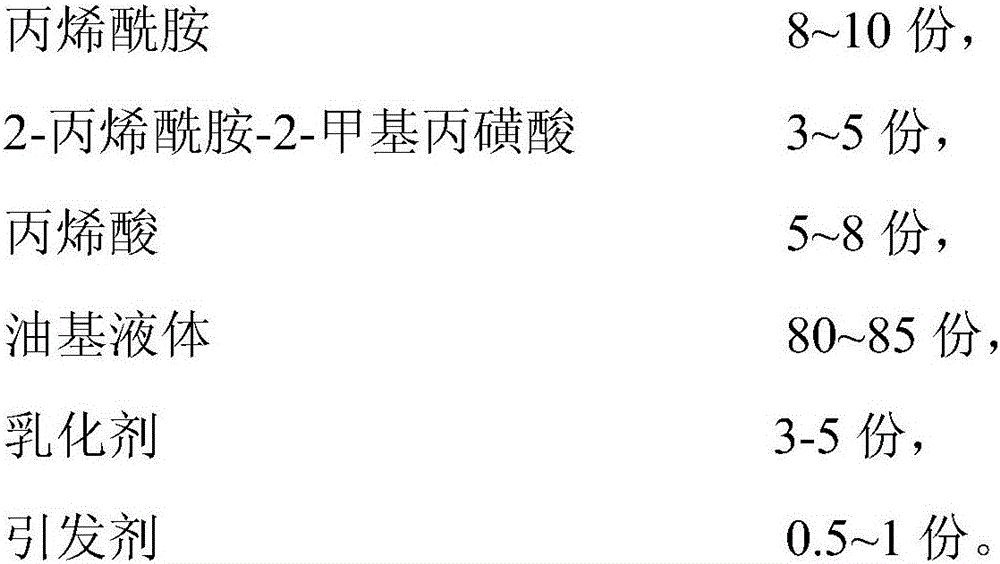

[0027] Dissolve 8g of acrylamide, 3g of 2-acrylamide-2-methylpropanesulfonic acid and 5g of acrylic acid in 50mL of water, add dropwise 1wt% sodium hydroxide solution to adjust the pH of the solution to 9, to obtain aqueous solution I; Dissolve in 20ml of water to form aqueous solution II; add 100mL of white oil to the four-necked flask, and add solution I to the four-necked flask, add 3g of SP-80 under stirring conditions and fill with nitrogen to exhaust oxygen; heat the mixed solution in a water bath to After 80°C, slowly drop solution II into the four-necked flask, continue to blow nitrogen and stir for 4 hours, then stop the reaction, cool the solution to room temperature, and the obtained white viscous liquid is the compound system of acrylamide polymer and oil base .

[0028] The apparent viscosity of the compound system of acrylamide polymer and oil base is 112mPa.s, which meets the pumping requirements of on-site construction and has good rheological properties.

Embodiment 2

[0030] 10g of acrylamide, 5g of 2-acrylamide-2-methylpropanesulfonic acid and 8g of acrylic acid were dissolved in 80mL of water, and 1.5wt% sodium hydroxide solution was added dropwise to adjust the pH of the solution to 9 to obtain aqueous solution I; Dissolve potassium sulfate in 20g water to form aqueous solution II; add 110mL white oil to the four-necked flask, and add solution I to the four-necked flask, add 3g SP-80 under stirring conditions and fill with nitrogen to exhaust oxygen; heat the mixed solution in a water bath After reaching 90°C, slowly drop solution II into the four-neck flask, continue to blow nitrogen and stir for 4 hours, then stop the reaction, cool the solution to room temperature, and the obtained white viscous liquid is a compound of acrylamide polymer and oil base system.

[0031] The apparent viscosity of the compound system of acrylamide polymer and oil base is 105mPa.s, which meets the pumping requirements of on-site construction and has good rh...

Embodiment 3

[0033] 9g of acrylamide, 4g of 2-acrylamide-2-methylpropanesulfonic acid and 6g of acrylic acid were dissolved in 80mL of water, and 1wt% sodium hydroxide solution was added dropwise to adjust the pH of the solution to 8 to obtain aqueous solution I; 0.5g of persulfuric acid Potassium was dissolved in 20g of water to form aqueous solution II; 100mL of white oil was added to the four-necked flask, and solution I was added to the four-necked flask, and 3g of SP-80 was added under agitation and nitrogen exhausted; the mixed solution was heated in a water bath to After 90°C, slowly drop solution II into the four-necked flask, continue to blow nitrogen and stir for 3.5 hours, then stop the reaction, cool the solution to room temperature, and the obtained white viscous liquid is a compound of acrylamide polymer and oil base system.

[0034] The apparent viscosity of the compound system of acrylamide polymer and oil base is 110mPa.s, which meets the pumping requirements of on-site co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com