Tire mold side panels and tire molds

A tire mold and side plate technology, applied in the field of tire mold side plates and tire molds, can solve problems such as easily damaged movable type blocks or side plates, and reduced mold accuracy, and achieve the effects of ensuring appearance, avoiding safety accidents, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

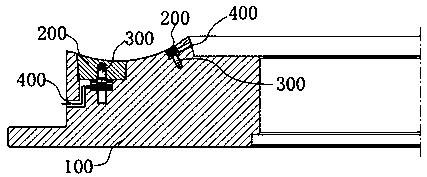

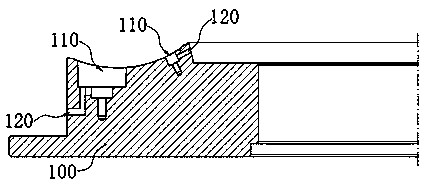

[0048] This embodiment provides a tire mold side plate, combined with figure 1 and figure 2 , the tire mold side plate includes a base 100, a movable type block 200, a connector 300 and a driving member; Between the movable type blocks 200 , the driving member is in transmission connection with the connecting member 300 and can drive the connecting member 300 to rotate, so that the movable type block 200 moves relative to the groove 110 to fit into the groove 110 or extend out of the groove 110 .

[0049]In the side plate of the tire mold provided in this embodiment, a connecting piece 300 is connected between the groove 110 and the movable type block 200, wherein the connecting piece 300 is in transmission connection with the driving piece, and the driving piece can drive the connecting piece 300 to rotate. During the rotation of 300, the movable type block 200 can move relative to the groove 110 to fit into the groove 110 or protrude from the groove 110; as can be seen fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com