Intelligent double-mould hydraulic tire curing press and mould adjusting method

A tire vulcanization and intelligent technology, applied in the field of intelligent dual-mode hydraulic tire vulcanizing machine and its mold adjustment, can solve the problems of poor centering repeatability, complex structure, huge equipment, etc., and achieve the effect of reducing the influence of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

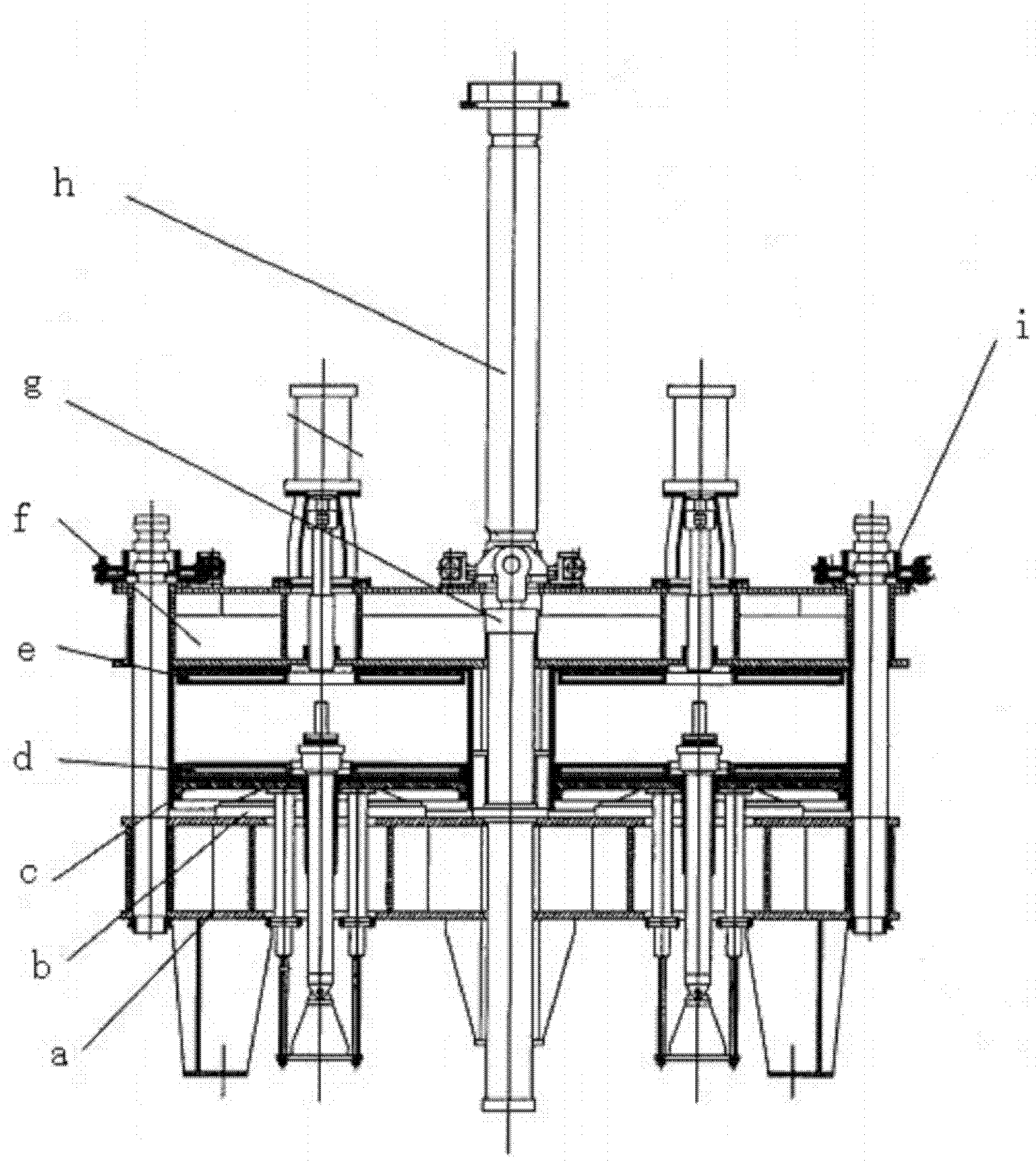

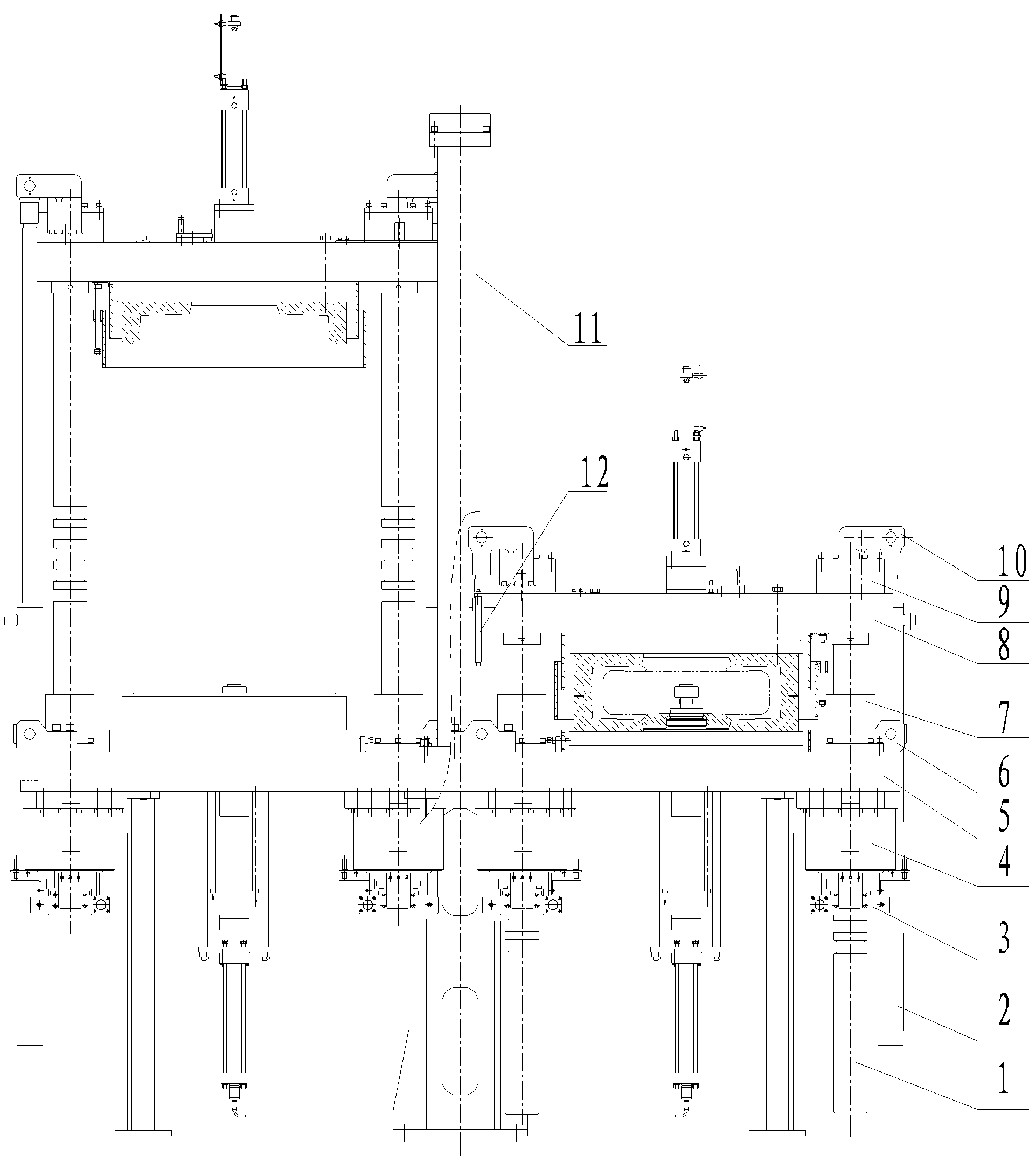

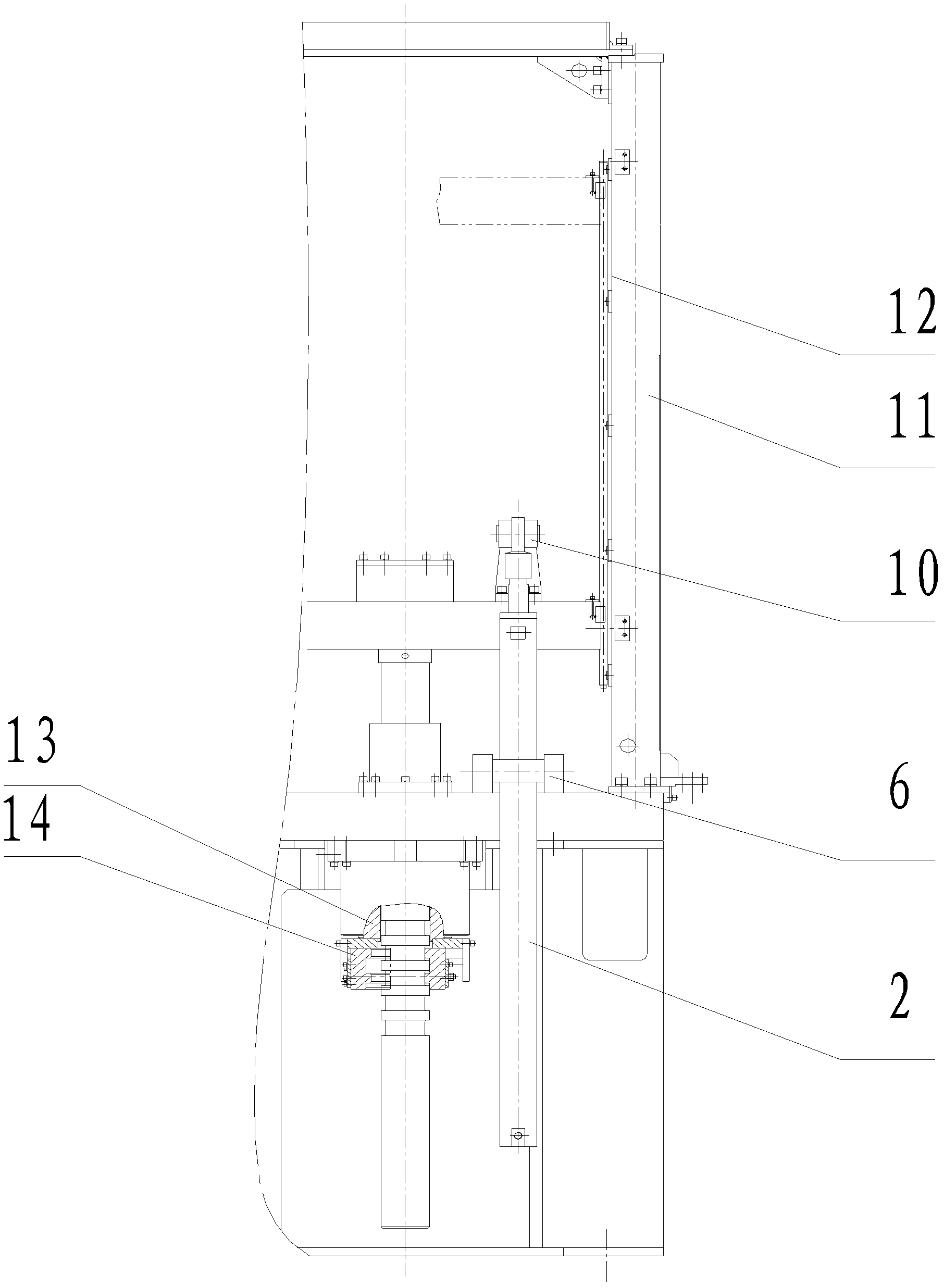

[0041] Such as Figure 2 to Figure 8 As shown, an intelligent dual-mode hydraulic tire curing machine includes a guide rod 1, a mold opening and closing cylinder 2, a mold locking mechanism 3, a pressurizing cylinder 4, a lower plate 5, a fixed lower bracket 6, an upper plate 8, and a fixed upper bracket 10 and support 11; the lower plate 5 is connected to the fixed lower support 6, the upper plate is connected to the fixed upper support 10 and also includes a displacement detection device 12, an electrical system and a PLC, the pressurized oil cylinder 4 and the clamping mechanism 3 At the same time, it is located on the guide rod 1. The end of the piston rod 13 of the pressurized cylinder 4 is tightly connected with the clamping mechanism 3. The cylinder bottom of the pressurized cylinder 4 is installed on the lower side of the lower plate 5 or the upper side of the upper plate 8. The rod 1 is provided with a plurality of annular grooves, any two of which are matched with th...

Embodiment 2

[0055] Another specific structure of the present invention, this intelligent dual-mode hydraulic tire vulcanizing machine is the same as Embodiment 1 except for the following features: the displacement detection device 12 is a displacement sensor, and the displacement sensor includes an external magnetostrictive displacement sensor, a position magnet 1. Install the clip and the connecting plate, the external magnetostrictive displacement sensor is installed on the support 11 by installing the clip, the position magnet is constrained on the external magnetostrictive displacement sensor, and is connected with the connecting plate installed on the upper plate 8 simultaneously. The position magnet is constrained on the external magnetostrictive displacement sensor and can slide freely in a straight line. It is connected with the displacement sensor connection plate installed on the upper plate 8. The connecting rod can rotate at any angle with a cone angle less than 20 degrees. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com