Viscoelastic surfactant weighted fracture fluid, and preparation method thereof

A surfactant and viscoelastic technology, applied in the field of viscoelastic surfactant aggravating fracturing fluid and its configuration, can solve problems such as easily broken gelled water, and achieve the effect of strong temperature resistance, shear resistance and density increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Viscoelastic Surfactants in Isopropanol

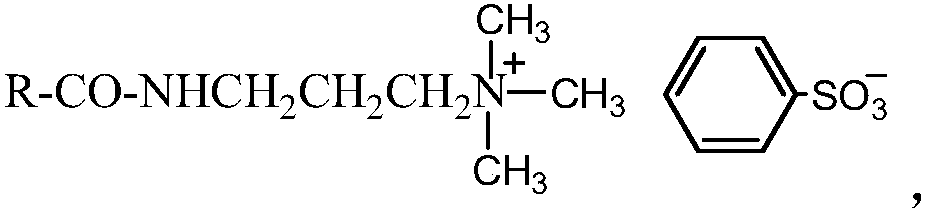

[0026] Add 211g (0.5mol) of erucamidopropyldimethyl tertiary amine and 148g of isopropanol into a 500ml reactor with a stirring and cooling device, heat to 60°C, and slowly add 86g (0.5mol) of methyl benzenesulfonate dropwise. ), ensure that the reaction temperature is no more than 70 DEG C, and continue to react for 2 hours after dropping, to obtain the isopropanol solution of the erucamide propyltrimethylbenzenesulfonic acid quaternary ammonium salt of the viscoelastic surfactant.

Embodiment 2

[0028] Preparation of Viscoelastic Surfactants in Isopropanol

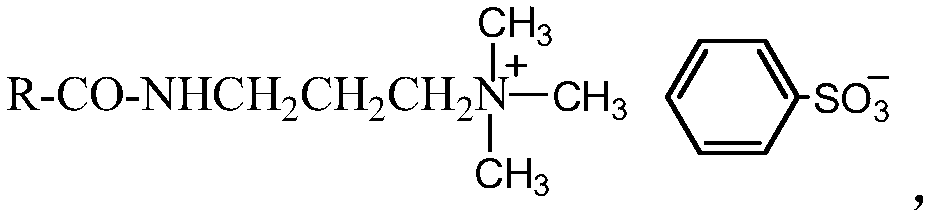

[0029] Add 366g (1mol) of oleic acid amidopropyl dimethyl tertiary amine and 269g of isopropanol into a 1L reaction kettle with a stirring and cooling device, heat to 60°C, slowly add 172g (1mol) of methyl benzenesulfonate dropwise, Ensure that the reaction temperature does not exceed 70° C., and continue to react for 2 hours after the drop is completed to obtain an isopropanol solution of oleic acid amidopropyltrimethylbenzenesulfonic acid quaternary ammonium salt of viscoelastic surfactant.

Embodiment 3

[0031] Weighted fracturing fluid configuration

[0032] A component: the isopropanol solution 1g, 20gCaCl 2 , 0.2g industrial hydrochloric acid, and 76.8g water were mixed evenly, and the initial viscosity was 32mPa·s.

[0033] Component B: 2 g of isopropanol solution of oleic amidopropyltrimethylbenzenesulfonic acid quaternary ammonium salt obtained in Example 2.

[0034] A component is mixed with B component to obtain a weighted fracturing fluid with an initial viscosity of 370mPa·s and a density of 1.157g / cm 3 . At 110°C, shear rate 170s -1 Keep it for 2 hours, and the minimum viscosity is 63mPa·s, meeting the requirement of not less than 50mPa·s for fracturing construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com