Manufacturing method for large-strain-resistant corrosion-resistant seamless line pipe for marine environment R-Lay laying

A technology of seamless line pipe and large strain resistance, which is applied in the field of marine resource exploitation and oil and gas transportation, can solve the problems of unmentioned corrosion resistance and other problems, and achieve good resistance to HIC and SSC performance, good use effect, and good welding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

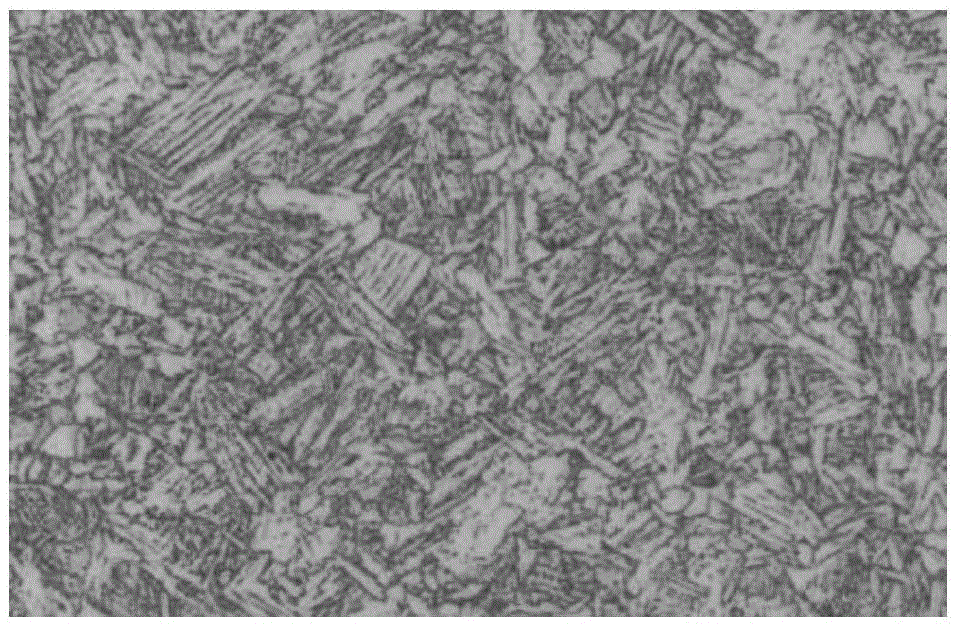

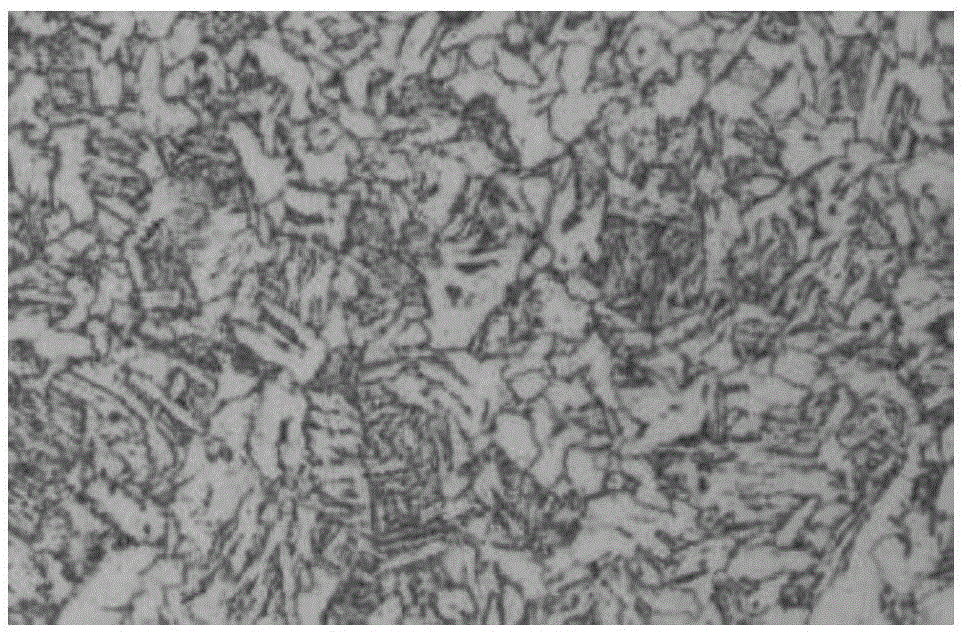

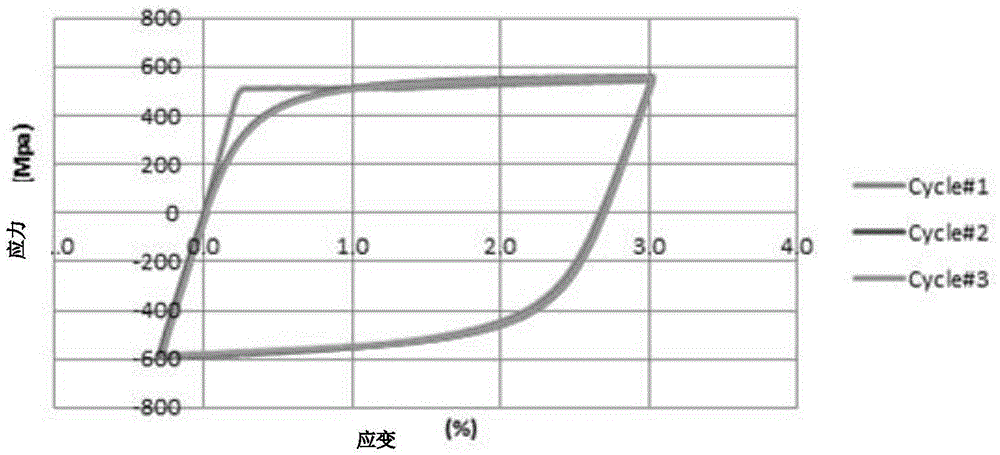

[0018] The manufacturing method of the large-strain and anti-corrosion seamless line pipe for marine environment R-Lay laying of the present invention is described in conjunction with the accompanying drawings.

[0019] The present invention relates to a method for manufacturing large-strain, corrosion-resistant, high-strength seamless line pipes for R-Lay laying in marine environments. A line pipe satisfying corrosion-resistant high-strength ≥ 415MPa for acidic environments, the method includes the following steps:

[0020] a. Ingredients The composition weight % of large strain and corrosion resistant seamless line pipe for marine environment R-Lay laying is: C0.05~0.13%, Si0.20~0.40%, Mn1.0~1.40%, P≤ 0.010%, S≤0.002%, Ni0.05~0.30%, Cr0.05~0.30%, Mo0.05~0.15%, Als0.010~0.050%, N≤0.010%, Nb0.010~0.050%, V0. 03~0.08%, Cu0.05~0.25%, Ti0.008~0.030%, Ca0.0005~0.0040%, Pb≤0.020%, Sn≤0.020%, As≤0.030%, Sb≤0.015%, Bi≤0.015% , B≤0.0005%, the balance is Fe and impurities; carbon equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com