Rapid drill stem hoisting adapter

A drill pipe, fast technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of not meeting the requirements of on-site construction, high labor intensity of workers, and low work efficiency, and meet the requirements of on-site construction and labor intensity of workers. The effect of low and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The embodiments of the present invention will be described below in conjunction with the drawings.

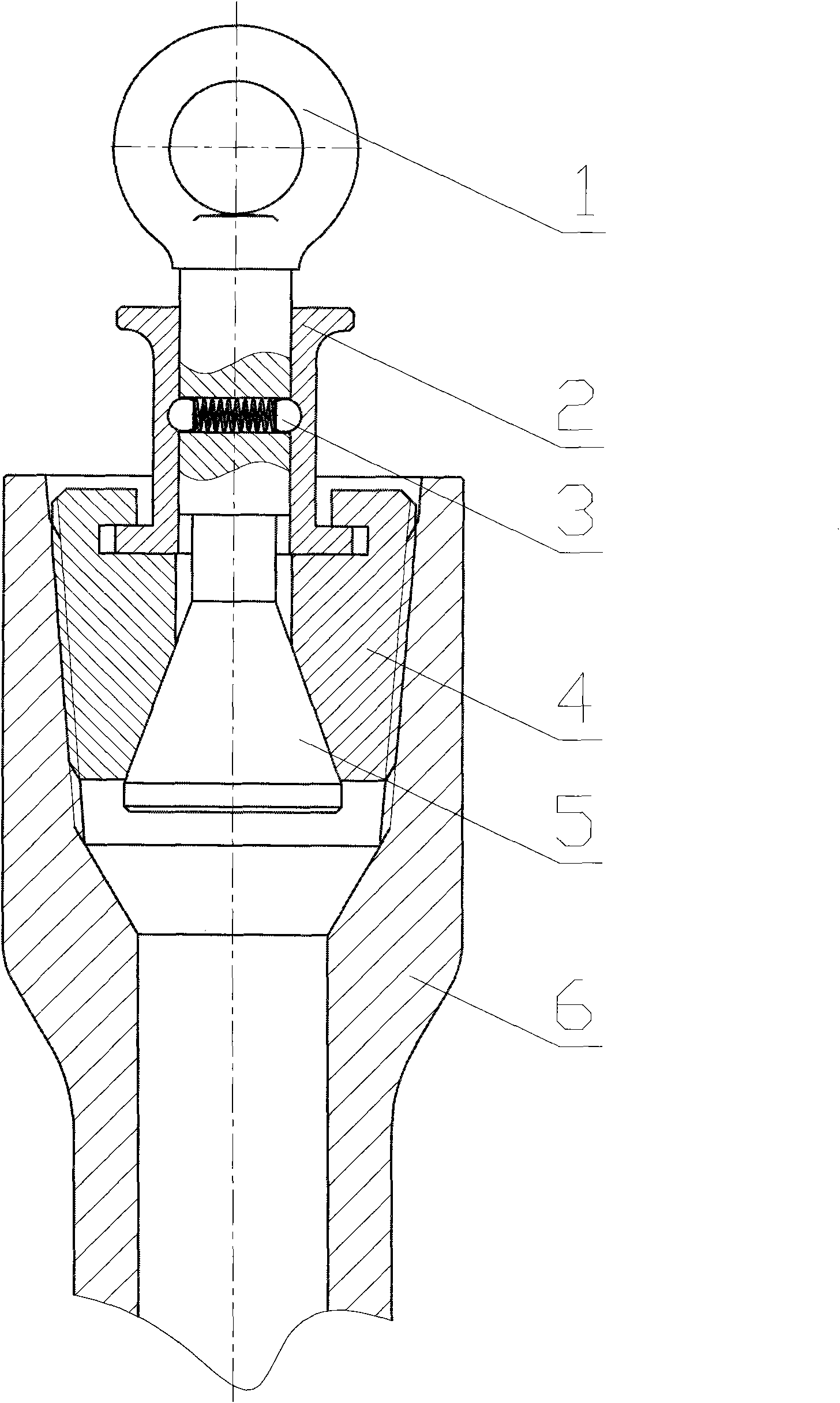

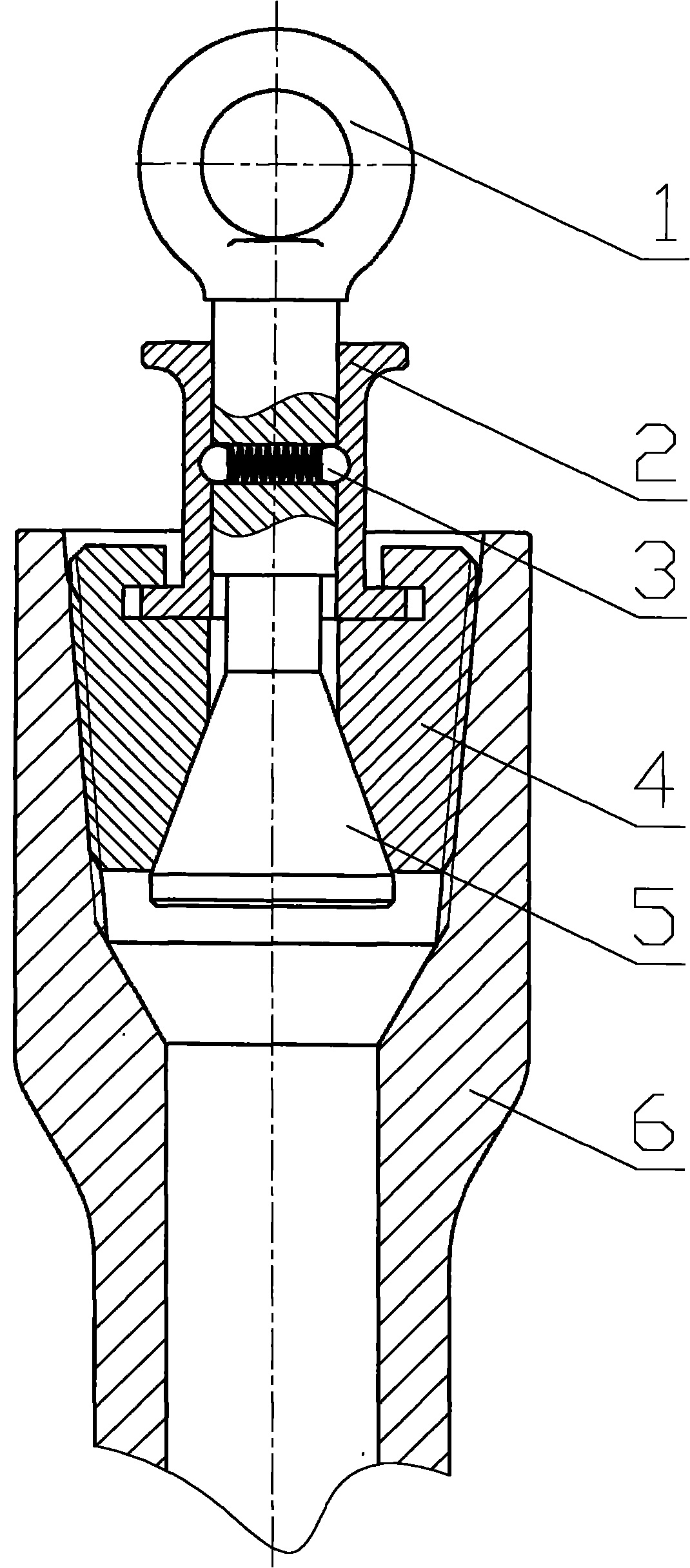

[0009] The embodiment of the present invention includes a lifting ring 1, a linkage sliding sleeve 2, a clamping block 4, a cone 5, and a drill rod 6. The outer wall of the clamping block 4 is an arcuate shape, and the outer wall of the clamping block 4 has a drill pipe thread, and the clamping block 4 The inner wall is conical with a large diameter at the lower end. Several blocks 4 form a cone suspended on the linkage sliding sleeve 2. The ring 1 passes through the linkage sliding sleeve 2. The lower part of the ring 1 is connected to the cone 5, and the upper end of the cone 5 has a small diameter at the lower end. The large diameter is matched with the inner wall of the clamping block 4, and the clamping block 4 is threadedly connected with the drill rod 6. A damping lock 3 is installed between the lifting ring 1 and the linkage sliding sleeve 2, so that the lifting rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com