Special plastic stabilizer for machine-made sand plastering mortar

A technology for plastering mortar and machine-made sand, applied in the field of building materials, can solve problems such as poor control of the gradation of machine-made sand, poor water retention of the mortar, and influence on the use of the mortar, so as to improve workability and construction, improve water retention, The effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

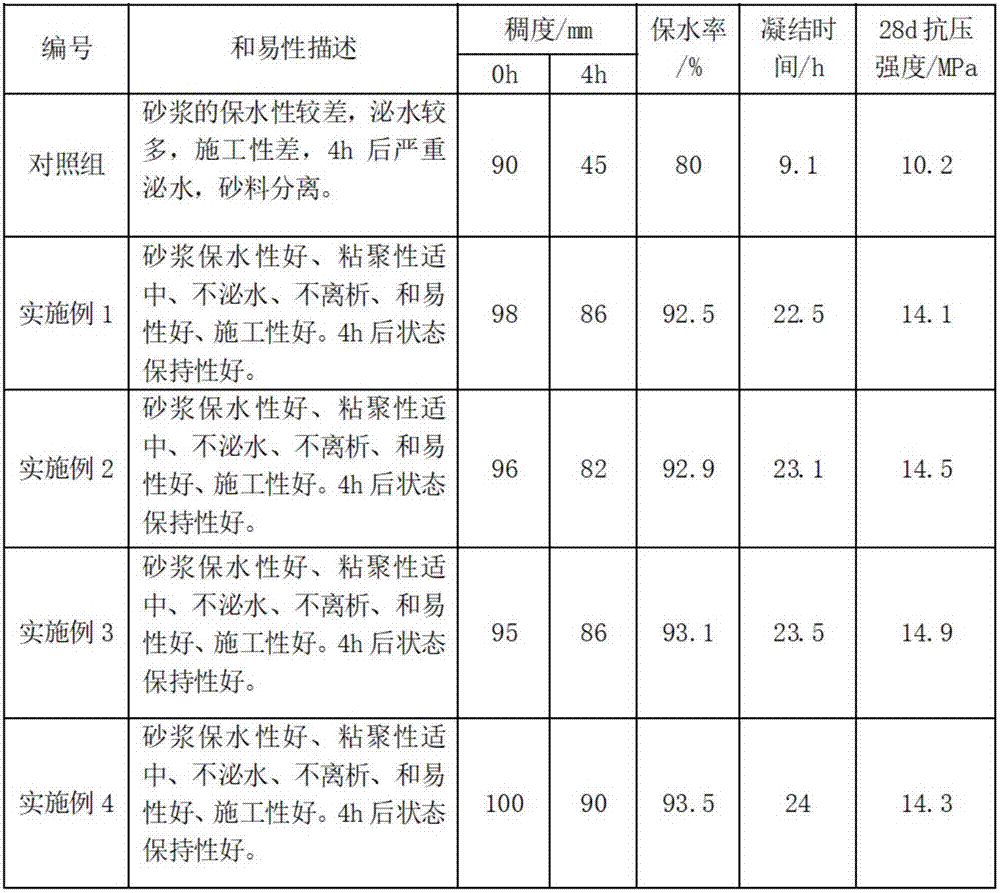

Examples

Embodiment 1

[0032] A special plastic stabilizer for machine-made sand plastering mortar, the ratio of its components is shown in Table 1:

[0033] components

[0034] Preparation method: Weigh each component according to the mass ratio in Table 1, add it into a gravity-free mixer, and mix well to obtain a special plastic stabilizer for machine-made sand plastering mortar.

Embodiment 2

[0036] A special plastic stabilizer for machine-made sand plastering mortar, the proportioning ratio of its components is shown in Table 2:

[0037] components

[0038] Preparation method: Weigh each component according to the mass ratio in Table 2, add it into a gravity-free mixer, and mix well to obtain a special plastic stabilizer for machine-made sand plastering mortar.

Embodiment 3

[0040] A special plastic stabilizer for machine-made sand plastering mortar, the ratio of its components is shown in Table 3:

[0041] components

[0042] Preparation method: Weigh each component according to the mass ratio in Table 3, add it into a gravity-free mixer, and mix well to obtain a special plastic stabilizer for machine-made sand plastering mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com