Continuous casting manufacturing process of ultra-thick slabs for hydropower station pressure vessel steel

A technology of extra-thick slabs and pressure vessels, which is applied in the field of continuous casting production technology of extra-thick slabs for pressure vessels of hydropower stations, can solve problems such as surface transverse cracks, center segregation, and surface depressions, and achieve smooth production process easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

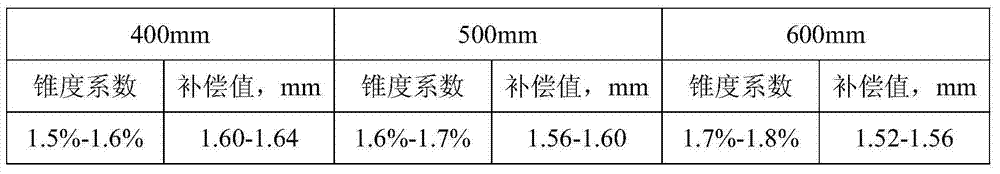

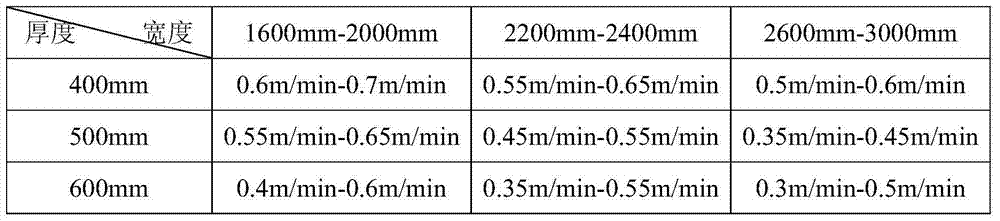

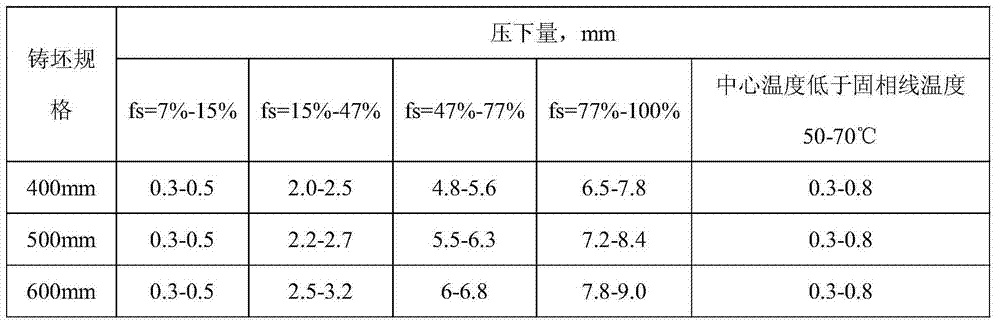

[0028] When a steel plant casts 400mm×2000mm hydropower station pressure steel pipe continuous casting slabs on a continuous casting machine, the mold slag composition is full carbon-9.45%, CaO-40.12%, SiO 2 -29.87%, Fe 2 o 3 -0.65%, MgO-1.55%, Al 2 o 3 -3.17%, K 2 O-0.22%, Na 2 O-4.47%, MnO 2 -0.25%, F-6.27%, volatile matter -3.98%, melting point 1220°C, viscosity 0.188PaS, density 0.82g / mL; casting speed 0.65m / min; taper coefficient set to 1.55%, compensation value to 1.62mm; The specific water volume of the secondary cooling is 0.24L / kg, the 3D nozzles at the side of the secondary cooling zone 8-9 have no water cooling, and the water volume of the central nozzle is 9L / min; the water volume of the central nozzle of the secondary cooling zone 10 is 5L / min, and the 3D nozzles at the side are without water Cooling; when fs=7% for light reduction scheme, the reduction is 0.3mm; when fs=45%, the reduction is 2.2mm; when fs=75%, the reduction is 5.6mm, fs=100% , the reducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com