Method for preparing corrosion-resistant super hydrophobic membrane layer on surface of aluminum alloy

An aluminum alloy surface, super-hydrophobic technology, applied in the preparation of corrosion-resistant super-hydrophobic film, in the field of preparation of corrosion-resistant super-hydrophobic film on the surface of aluminum alloy, can solve the problems of long duration, poor scalability, complex preparation process, etc. , to achieve the effects of high stability and durability, easy processing and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

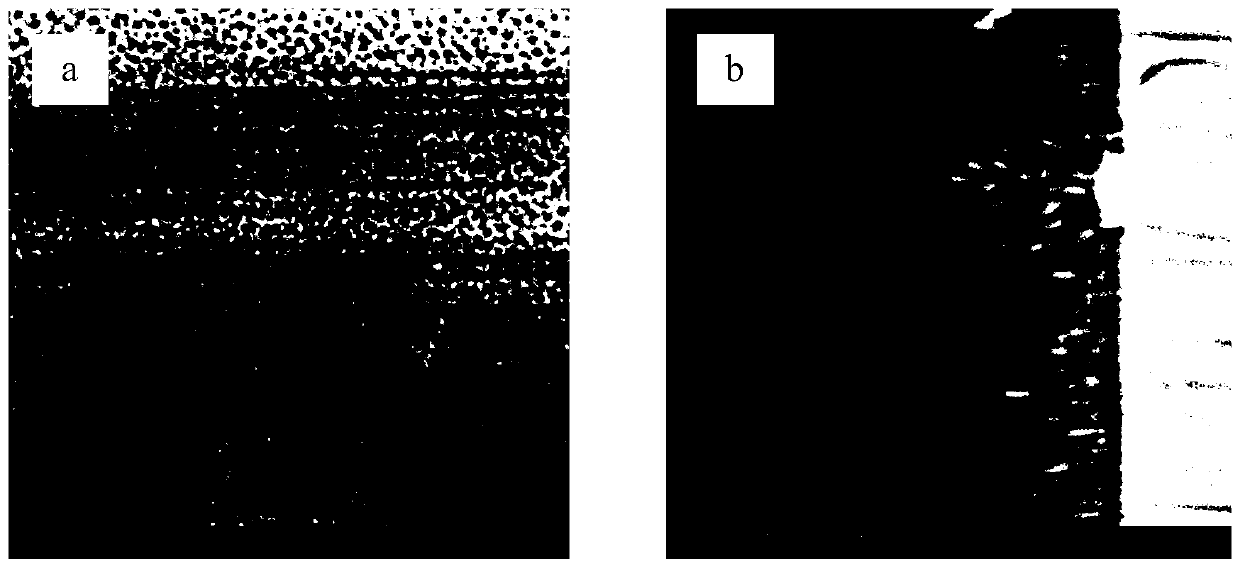

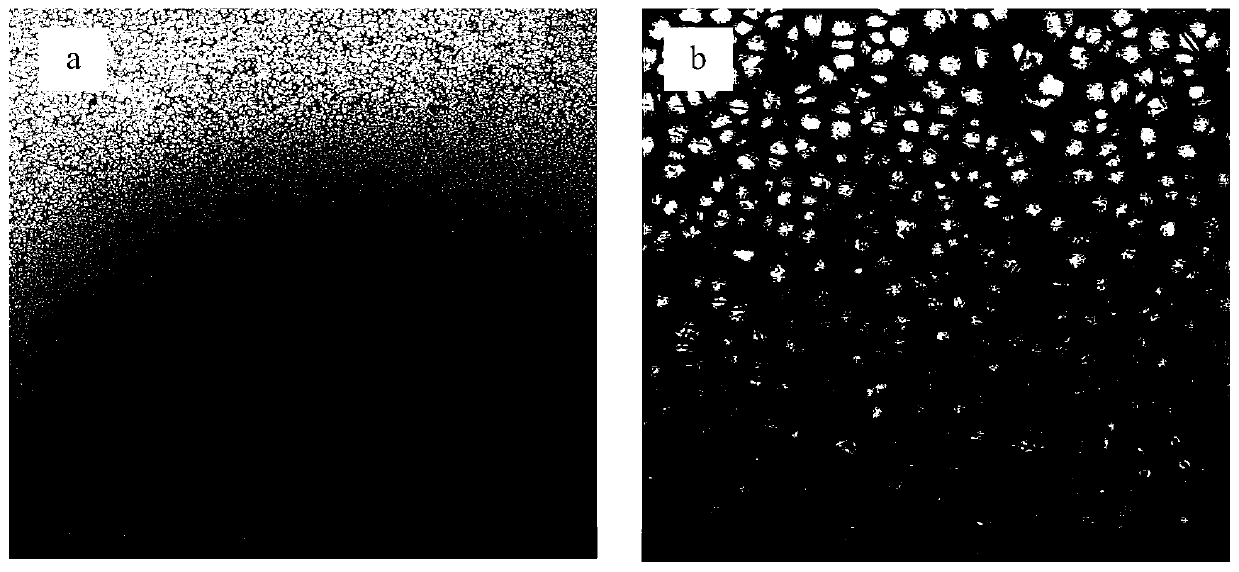

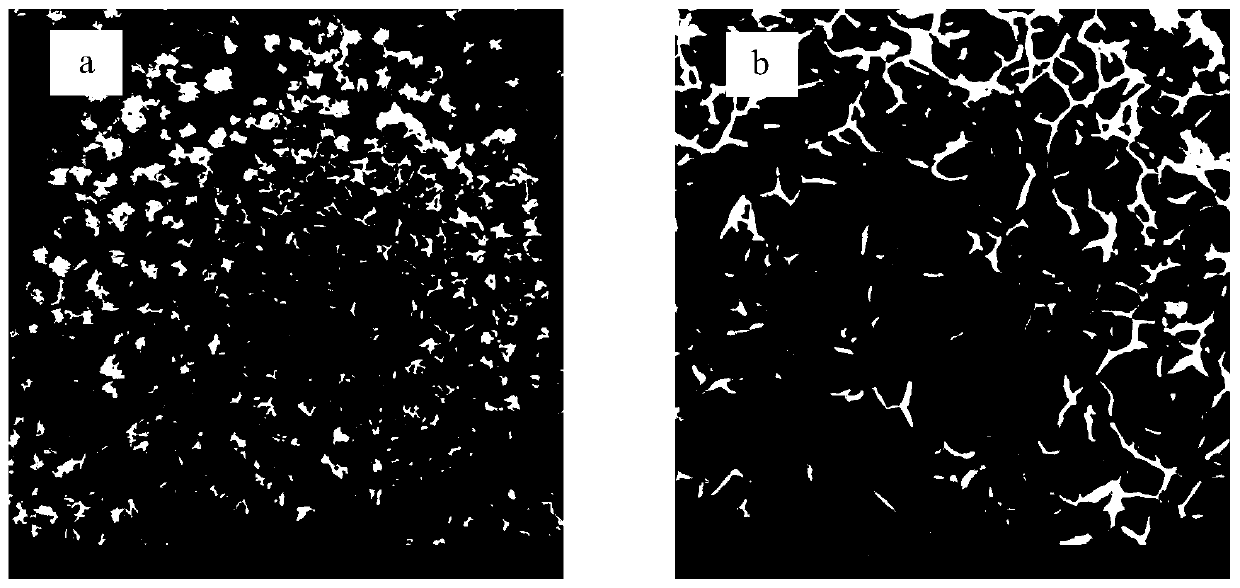

Image

Examples

Embodiment

[0033] The invention provides a method for preparing a corrosion-resistant super-hydrophobic film on the surface of an aluminum alloy, the method comprising the following steps:

[0034] 1) Pretreatment of the aluminum alloy (6061) sample: smooth the surface of the sample with 400-2000# silicon carbide sandpaper, and remove the surface scale. Then place them in deionized water and ethanol for 15 min each ultrasonically to remove surface oil, and dry at room temperature.

[0035] 2) Electrolytic polishing treatment, anodic oxidation treatment and hole expansion treatment are sequentially performed on the aluminum alloy substrate;

[0036] Among them: electrolytic polishing treatment: the pre-grinded aluminum alloy substrate is subjected to electrolytic polishing treatment, the aluminum alloy sample is connected to the anode of a constant current power supply, and the cathode is made of stainless steel as an inert electrode. The polishing liquid proportion is composed of 40% ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com