Compacting process of flexible pipe on transformer

A technology of transformers and hoses, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. It can solve the problems of deformation of the pressure plate, reduction of transformer anti-short circuit capacity, and uneven force on windings, etc., to achieve improved short circuit resistance. Low cost and uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

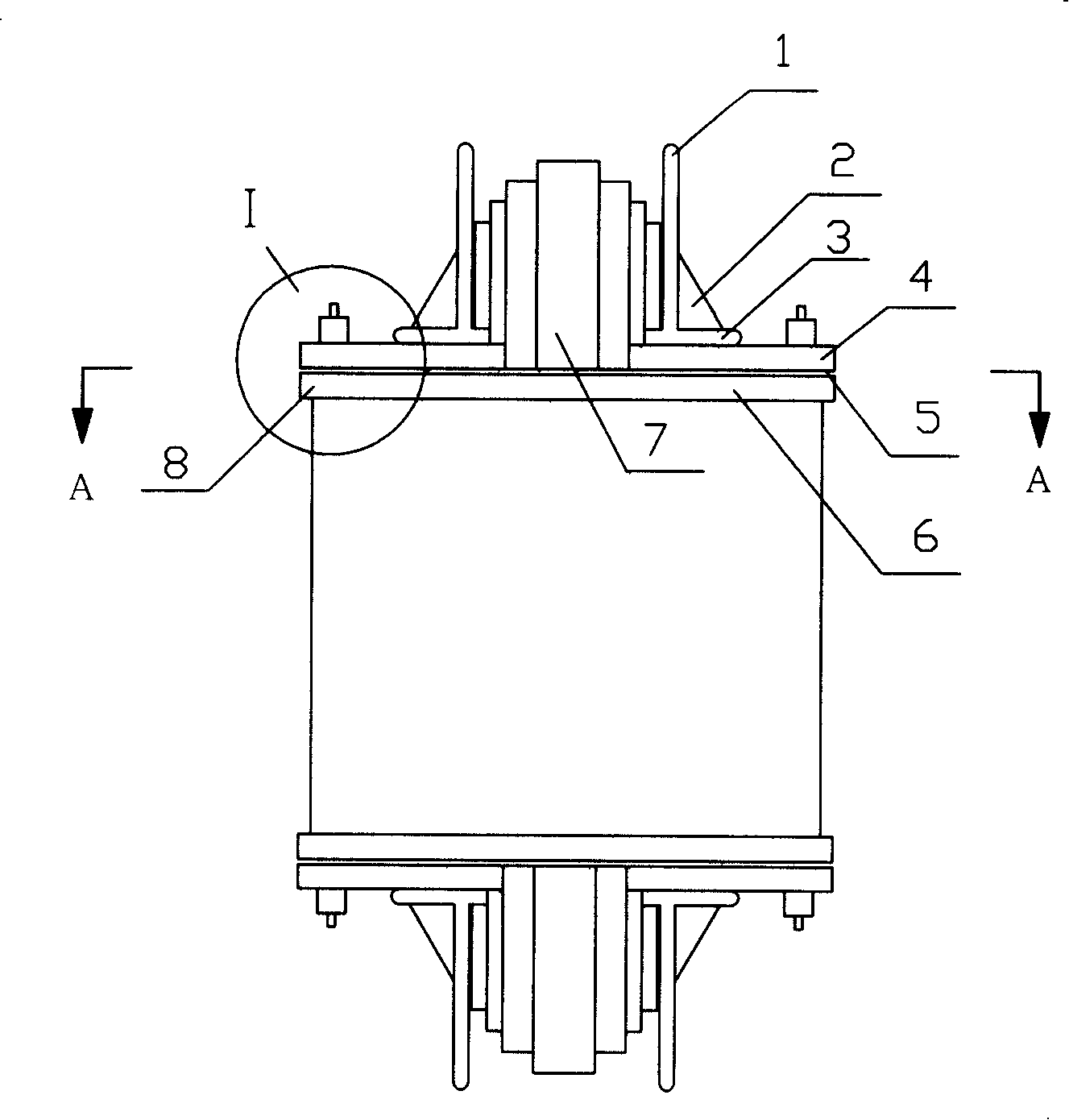

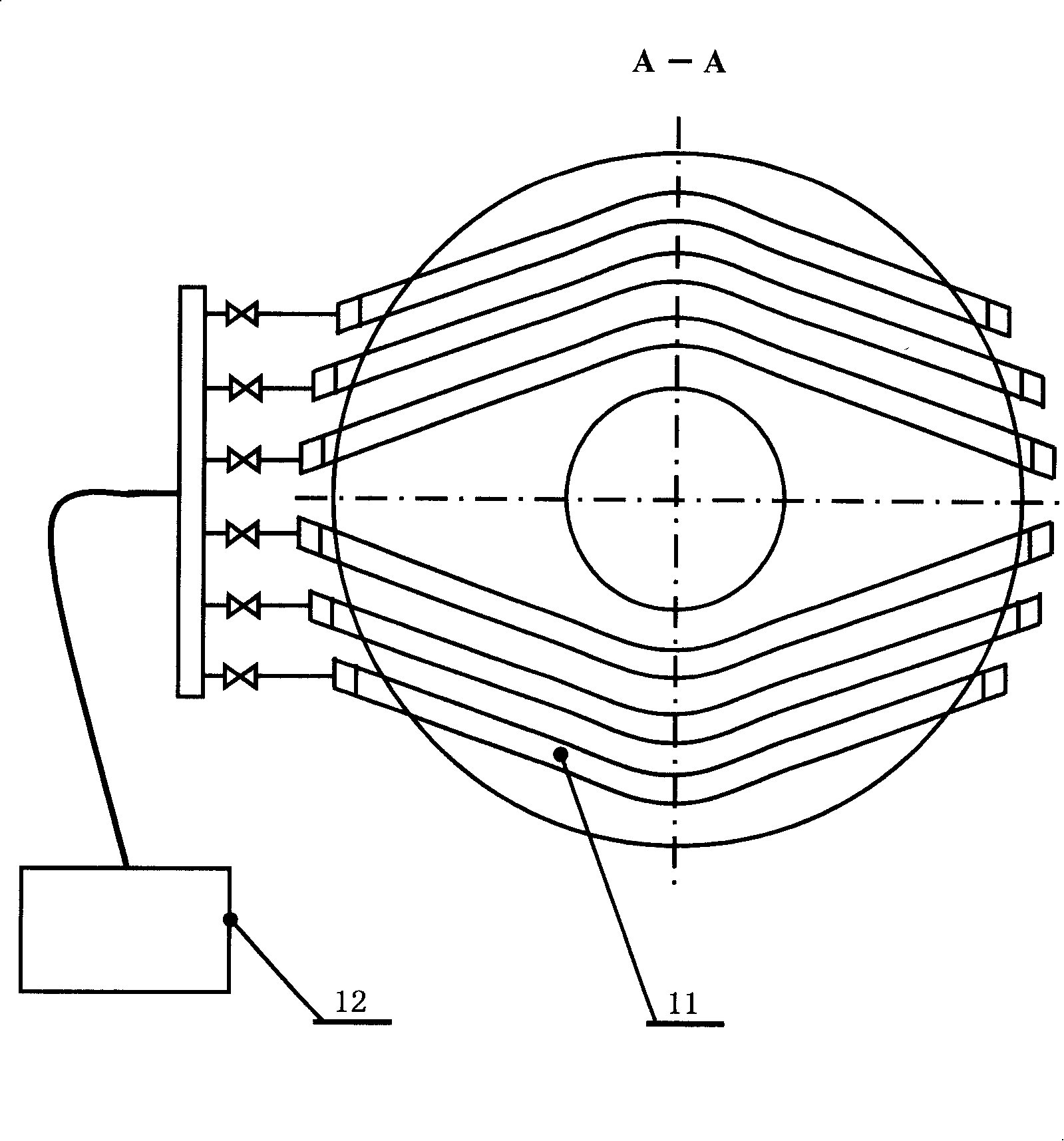

[0032] see Figure 1~3 , the implementation steps of the present invention are as follows:

[0033] (1) On the clips 1 at both ends of the transformer body, force-bearing substrates 3 are respectively arranged to make the force uniform.

[0034] (2) Level the iron core steps at both ends of the transformer body with insulating laminates 4, so that the inner surface of the insulating laminate 4 and the inner surface of the iron yoke 7 are on the same plane.

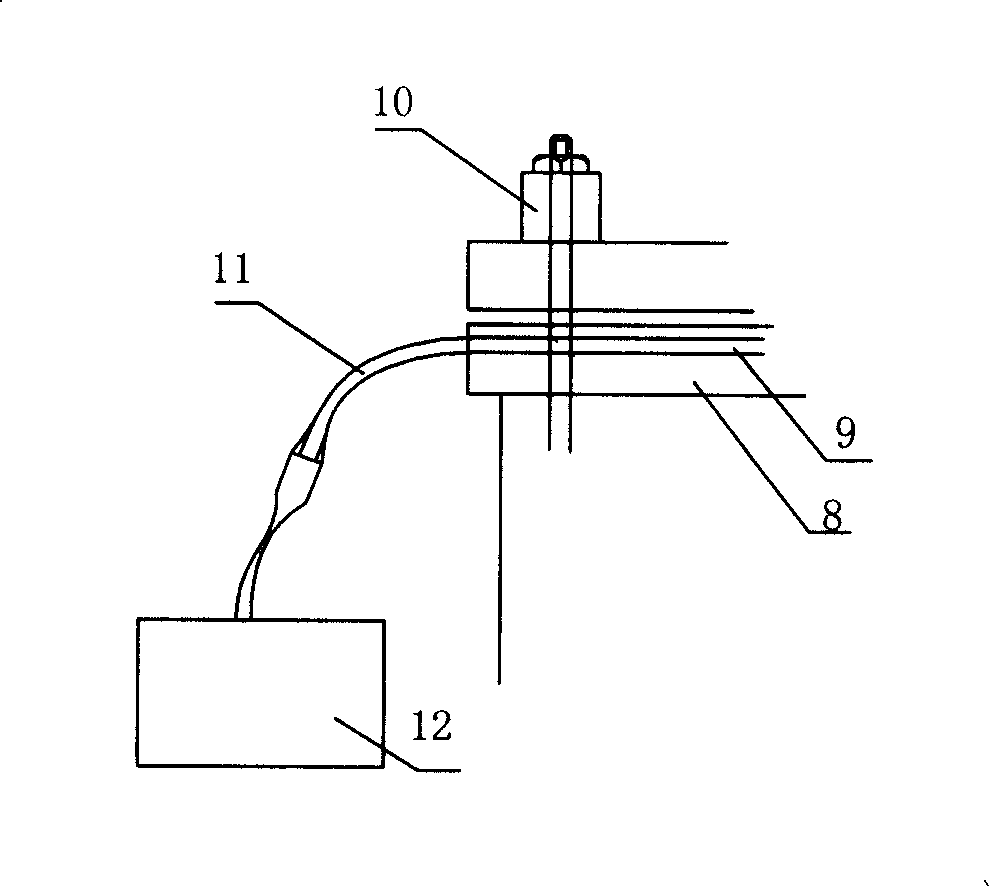

[0035] (3) A hose groove 9 is set on the upper body pressure plate 8 of the transformer body, and the size of the hose groove 9 is appropriate to the width and thickness of the hose 11 and a margin is left. For making the body stressed evenly, it is better that the hose groove 9 is symmetrically arranged on the upper body pressing plate 8. The density of the hose groove 9 is determined according to the required pressure of the transformer winding. The width of the hose groove 9 is preferably 100-110 mm, and the depth of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com