Anti-freezing process for blowout-preventing pipe and cable matched with water injection well test

A technology of blowout preventer and water injection well, which is applied in the directions of cable installation, measurement, electrical components, etc., can solve problems such as cable freezing, and achieve the effect of ensuring safety, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

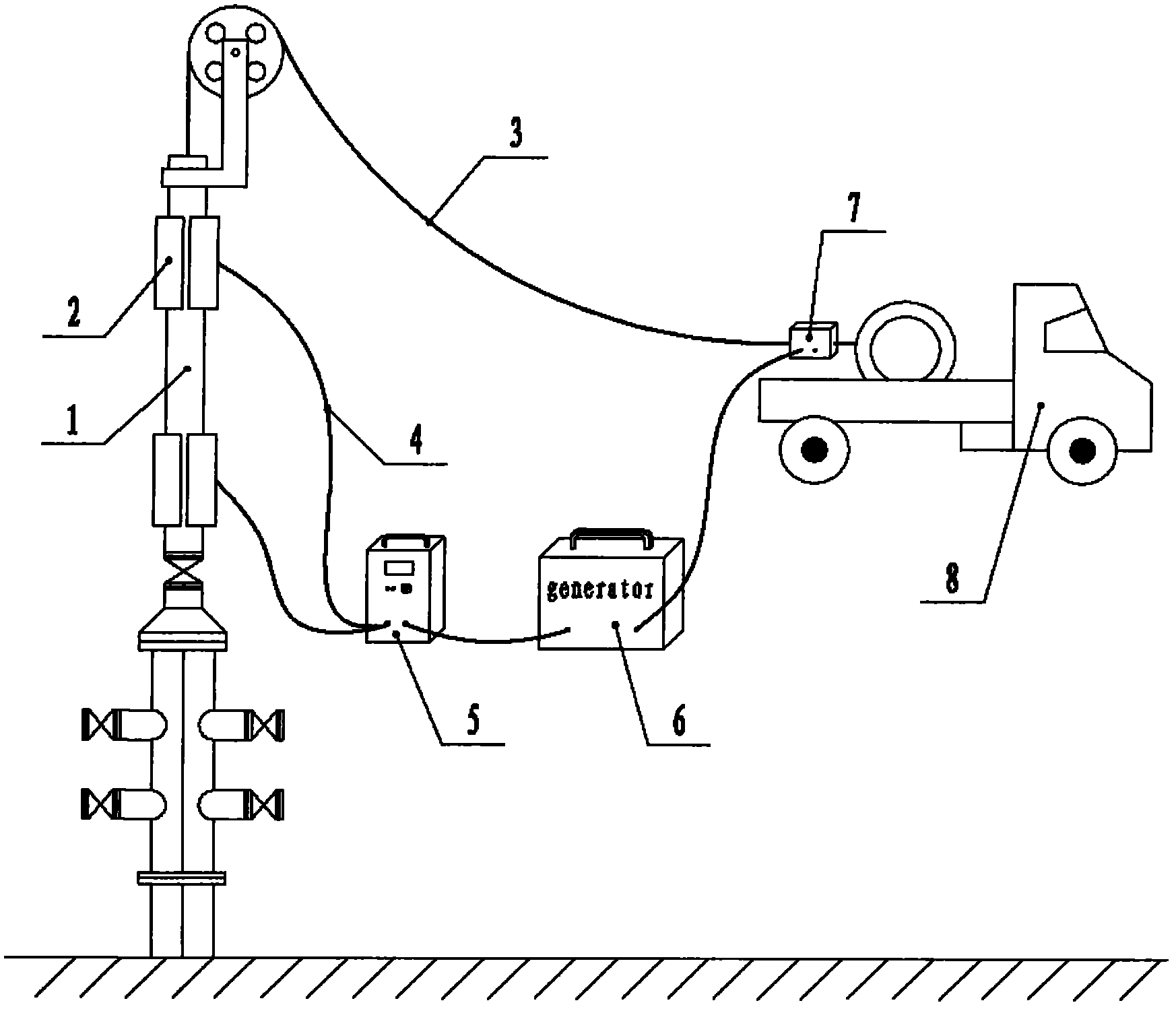

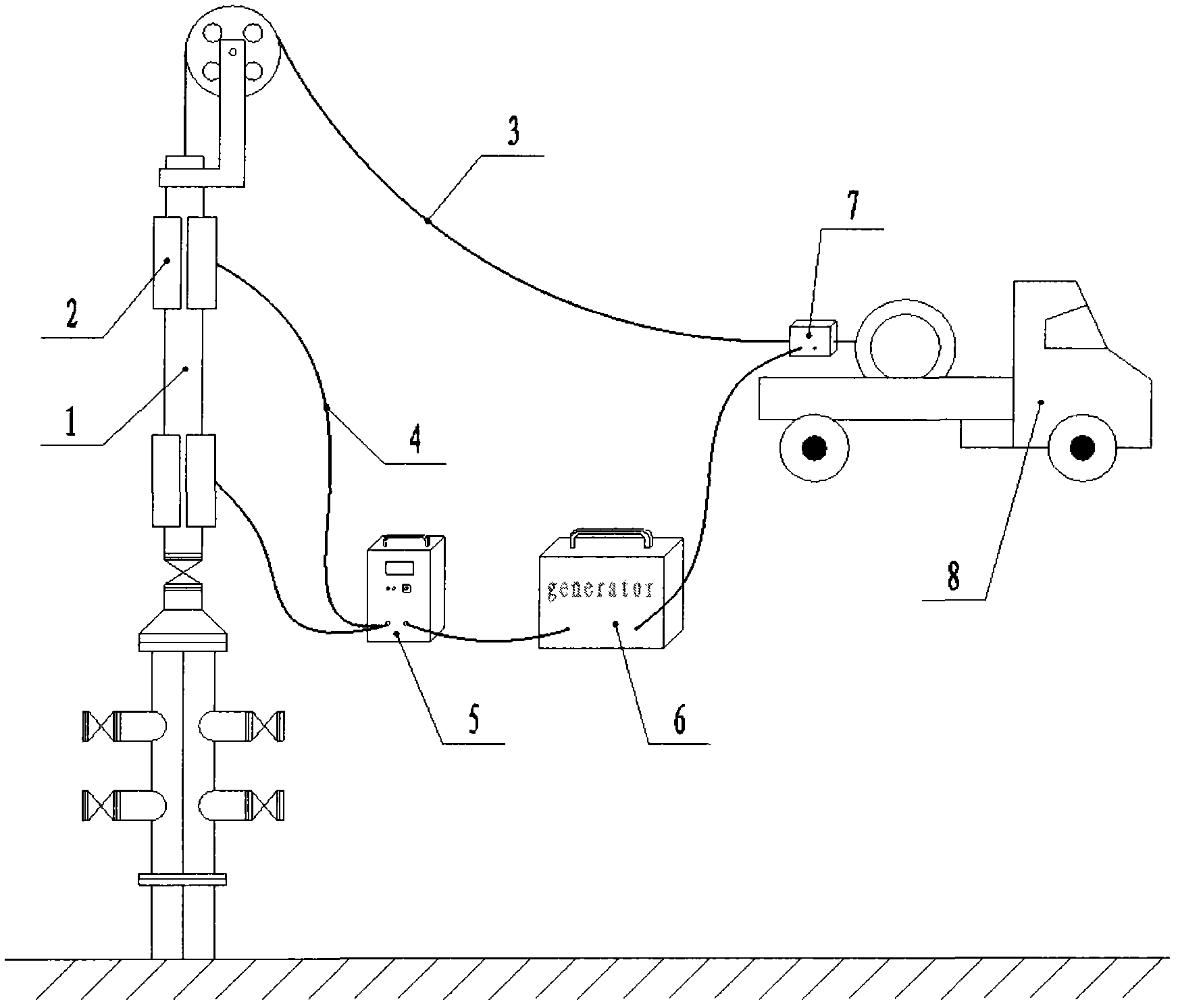

[0012] Below in conjunction with accompanying drawing, the present invention is described further: the present invention is realized by following device: blowout preventer 1, integrated coil 2, cable 3, multicore electric wire 4, heating power supply 5, generator 6, cable deicing The device 7 and the cable car 8 are composed of the integrated coil 2 surrounding the blowout preventer 1, the integrated coil 2 is connected to the output end of the heating power supply 5 through a multi-core wire 4, and the input end of the heating power supply 5 is connected to the generator 6 , the cable deicing device 7 is fixed on the position of the cable 3 in the cable car 8; the present invention is achieved through the following steps:

[0013] a. First, the heating power supply 5 converts the DC power provided by the generator 6 into a high-frequency current, and then provides it to the integrated coil 2. The integrated coil 2 and the nozzle 1 form an electromagnetic induction effect, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com