LED bulb lamp and method for manufacturing same

A technology for LED bulbs and LED light sources, which can be used in lampshades, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., and can solve the problems of complex structure, high cost, and troublesome assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Glass substrate

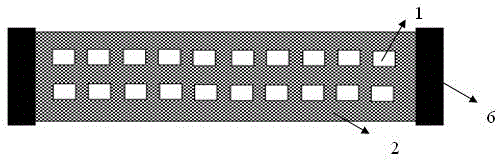

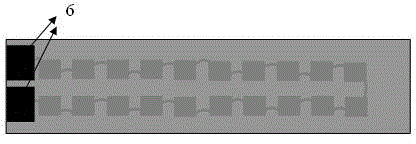

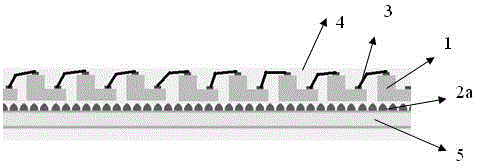

[0032] Select a glass substrate, perform mask etching on the surface of the glass substrate, and etch out an array of periodically arranged yurt-shaped protrusions. The protrusion period is about 5 μm, the bottom surface width is about 10 μm, and the height is about 2.5 μm. An aluminum nitride layer is coated on the surface of the patterned glass substrate, and then etched with a mask to etch out a patterned structure of mesh-like voids. The voids are regular equilateral hexagons with a side length of about 3 μm, adjacent The distance between the voids is about 3 μm-7 μm. Prepare electrodes on the surface of the glass substrate, paste and fix the LED chip, connect the chip and the chip, and connect the chip and the electrode through the wire. Cover the entire LED chip and all lead wires to maximize the light output of the LED chip and effectively protect the lead wires from being touched, so as to avoid the lead wires from being disconne...

Embodiment 2

[0033] Example 2 Comparison of test data of various LED bulb lamps

[0034] We conduct experiments on the following LED bulb lamps, divided into 5 groups, each with 15 lamps, group A is a traditional LED bulb lamp, consisting of a glass cover, lens, heat sink, aluminum substrate, power supply pre-installed cavity body, plastic connectors, lamp socket interface, light source, and power supply; group B is the LED bulb lamp prepared by the method of filling the air in the sealed glass lampshade with the glass substrate according to the present invention; group C is the glass substrate on the basis of group B. The method of the present invention is etched, and etched into a patterned substrate to prepare an LED bulb; group D is an LED bulb prepared by coating a layer of aluminum nitride layer on the surface of the patterned substrate on the basis of the preparation method of group C; Group E is the LED bulb lamp prepared after patterning the aluminum nitride layer according to ...

Embodiment 3

[0038] Example 3 Thermal Analysis Experiment of LED Bulb Lamps with Different Thickness Glass Sheets

[0039] Using the same 1023 chip and different substrate thicknesses, measure the LED light source in the air respectively, then use the same light source to install the ball bulb, vacuumize and then fill the mixed gas and seal it, measure the initial luminous flux after lighting and the stabilized luminous flux respectively Luminous flux, and calculate the heat accumulation rate, deduce the influence of glass substrates with different thicknesses on LED bulb lamps.

[0040] To prepare LED light sources, select glass sheets with thicknesses of 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.1mm, and 1.2mm, 15 pieces of each thickness, each glass There are two electrodes on the substrate, the chip is fixed with fluorescent glue on the substrate, the lead is connected between the chip and the chip, and the chip and the electrode, and the fluorescent glue is direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com