Device for roundness adjustment and supporting of penstock

A penstock and support device technology, applied in the field of hydropower penstock construction, can solve problems such as inability to use internal support, difficult long-term load-bearing, difficult production, etc., to achieve simple structure, convenient installation and adjustment, and easy reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

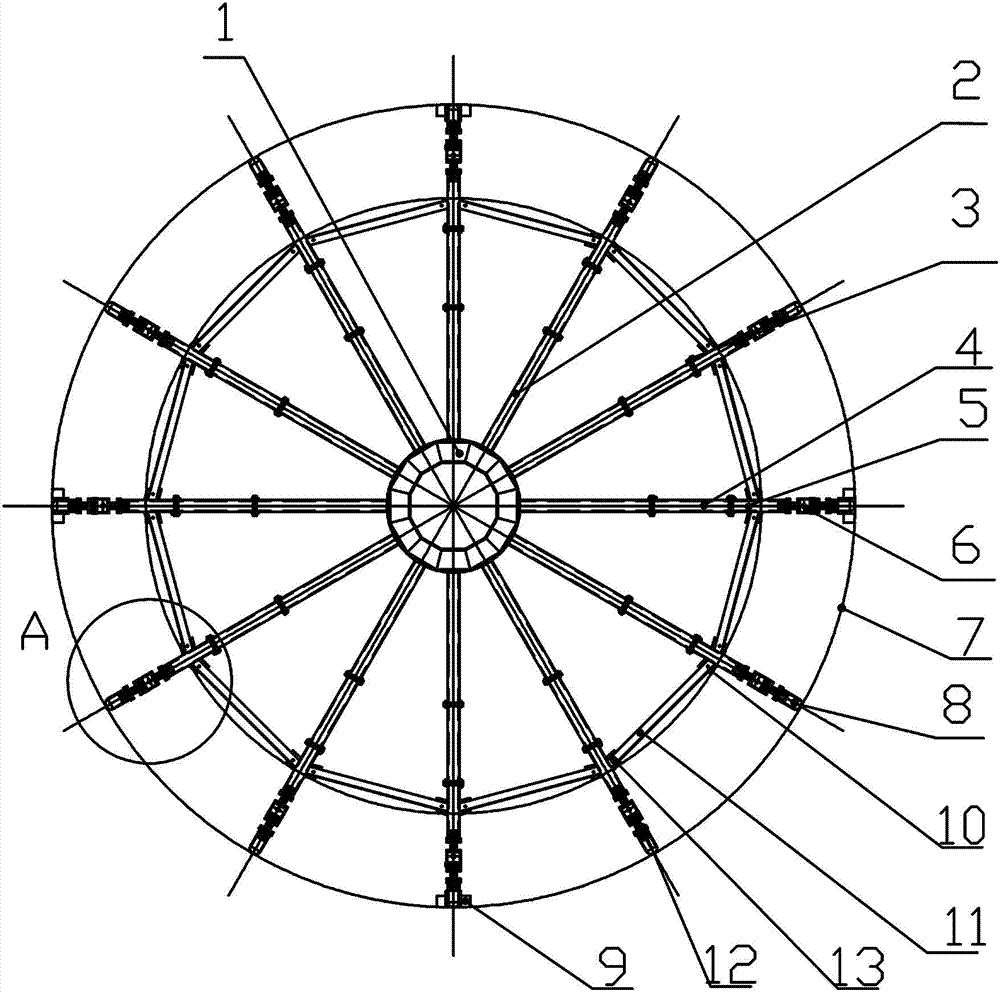

[0022] Such as figure 1 Among them, a penstock roundness adjustment and support device, including an inner hub 1, on the outer circumference of the inner hub 1, a plurality of support rod assemblies arranged in a circle are arranged; the inner hub 1 is assembled and welded by section steel, and supports The rod assembly is welded on the outer circumference of the inner hub 1 .

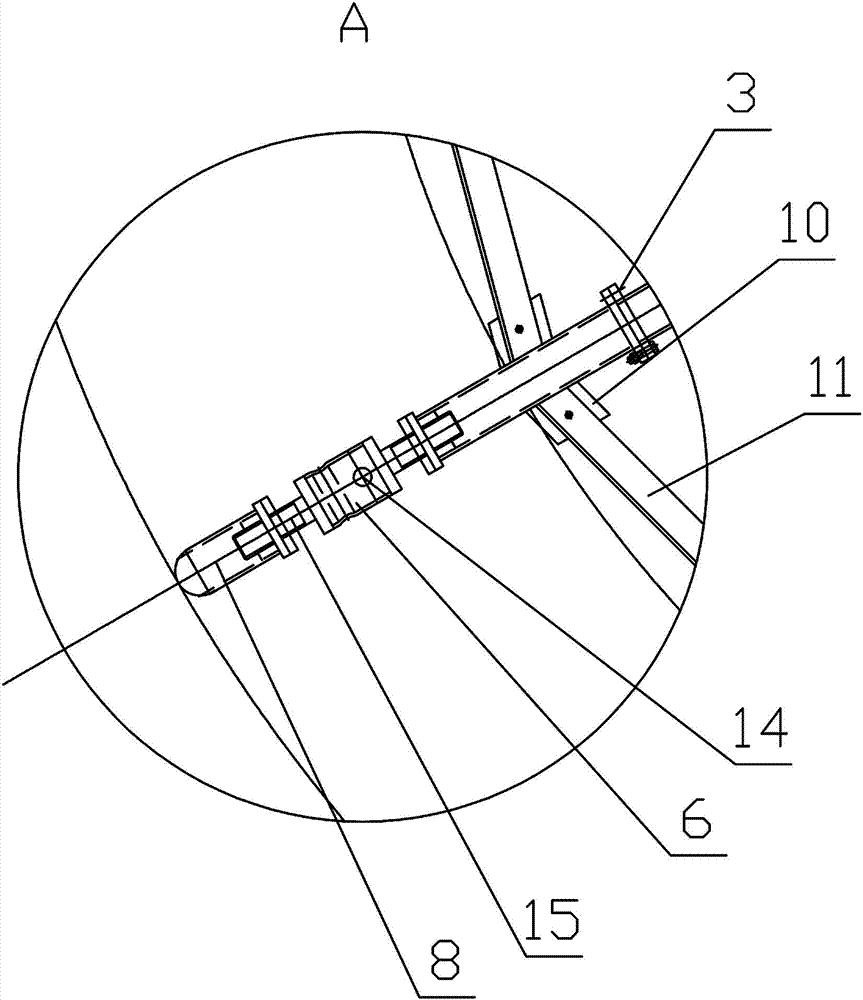

[0023] Such as figure 2 Among them, the support rod assembly is composed of at least three support rods, including the support rod connected to the inner hub 1, the end support rod 8 at the end contacting the pressure steel pipe 7, the connecting support rod and the end support rod The adjustment support bar 6 of 8;

[0024] Such as figure 2 Among them, the two ends of the adjustment support rod 6 are provided with studs 15, and the corresponding positions of the support rod and the end support rod 8 are provided with internal threads.

[0025] In an optimized solution, at the position correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com