A device and method for transporting cassettes

A technology of cassettes and handling mechanisms, applied in storage devices, transportation and packaging, electrical components, etc., can solve problems such as inability to handle, large handling capacity of stackers, and impact on production capacity, so as to solve the bottleneck of excessive handling capacity and reduce The effect of handling capacity and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described below with reference to the drawings.

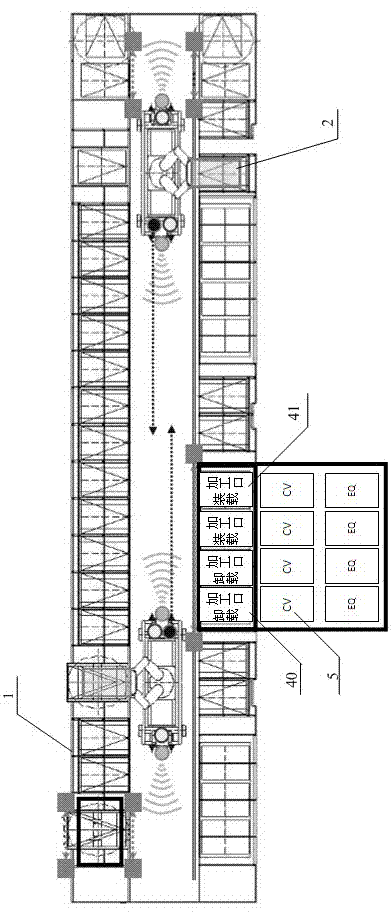

[0043] Such as image 3 Shown is a schematic diagram of a device for carrying cassettes in an embodiment of the present invention;

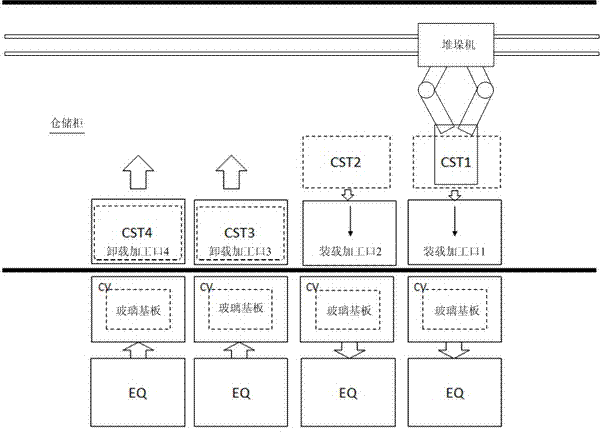

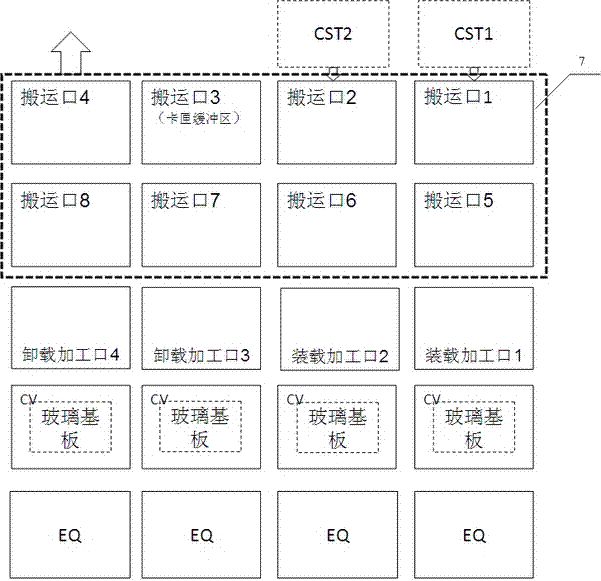

[0044] The device for transporting cassettes of the present invention is used for transporting cassettes between the stacker, the loading processing port and the unloading processing port of the storage cabinet, and includes:

[0045] The handling port area 7 arranged in the front section of the loading processing port and the unloading processing port includes at least two rows of handling ports, wherein the number of handling ports in each row of handling ports is the same as the loading processing port and unloading port. The total number of processing ports corresponds to that, and there is a row of handling ports adjacent to the loading and unloading ports. in figure 2 Shows a handling port area with two rows and four handling ports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com