Full-automatic production system and method for ostomy bag

A production system, fully automatic technology, used in transportation and packaging, envelope/bag manufacturing machinery, paper/cardboard containers, etc., which can solve the problems of material transfer taking a long time, inability to produce products, and difficulty in accurate positioning. Reduce artificial quality risk, improve deodorization and bacteriostatic effect, and reduce the effect of handling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described below by specific embodiments, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

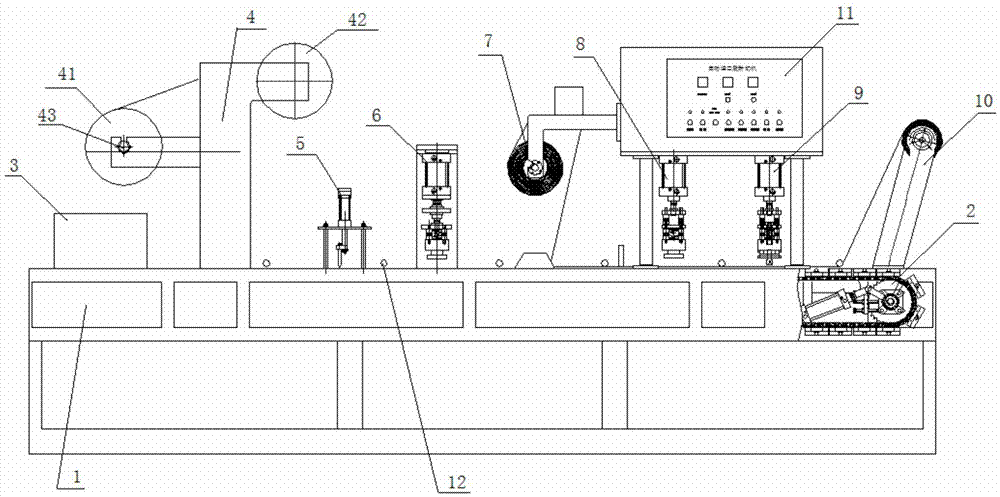

[0028] like figure 1 As shown, a fully automatic production system for ostomy bags, the system includes a horizontal worktable 1, a transmission part 2 is arranged on the horizontal worktable 1, the left side of the transmission part 2 is a chassis feeding device 3, and the right side is a waste film winding device 10.

[0029] Above the transmission component 2 are sequentially arranged from left to right a film roll supply device 4, a positioning ironing piece 5, a chassis ironing piece 6, a composite film roll supplying device 7, a stoma ironing piece 8, and a stoma sealing and cutting piece 9. The above-mentioned The components are fixedly installed on the horizontal workbench 1 and are electrically connected to the electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com