Manual stamping device

A punching device and punching die technology, which is applied in the field of aluminum alloy door and window processing equipment, can solve the problems of aluminum door and window profiles that are not easily washed off, multiple times of material handling, and low work efficiency, so as to reduce the labor intensity of workers, improve work efficiency, and punch holes. high pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

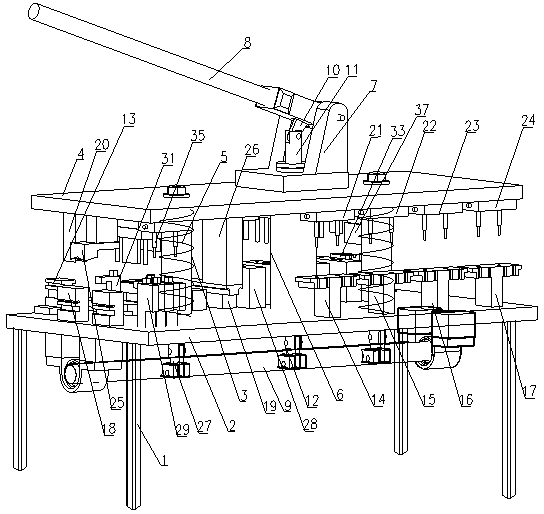

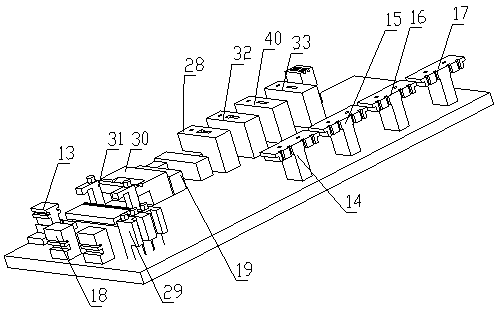

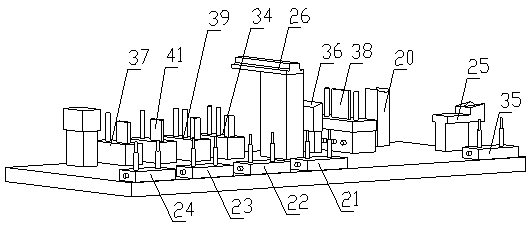

[0016] like Figure 1 to Figure 3 The shown manual punching device for processing aluminum alloy door and window components includes a frame 1, a lower template 2 is connected to the top of the frame 1, an upper template 4 is slidably connected to the lower template 2 through two sliding rods 3, and two return springs 5. It is located between the lower template 2 and the upper template 4, and is respectively sleeved on the outside of the two sliding bars 3. The sliding sleeve 6 is connected to the lower template 2 and is slidably connected with the upper template 4 and extends above the upper template 4. The hinge seat 7 is connected to the upper template 4. The top end of the sliding sleeve 6 is connected, one end of the lever 8 is hinged with the hinge seat 7 through the hinge shaft, the eccentric shaft 9 is rotatably connected und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com