Device for processing aluminum oxide ceramic by fiber laser and method thereof

A technology of alumina ceramics and fiber laser, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as reduced efficiency, low laser power, and incompetent processing methods and devices, and achieves excellent roundness and high efficiency. High, good punching effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

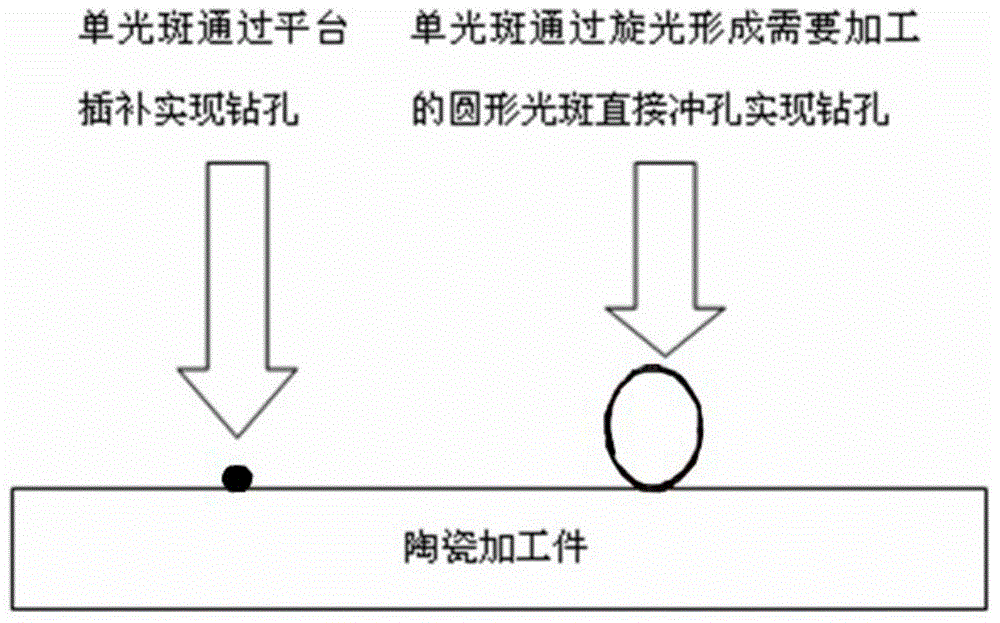

[0024] Using an optimized laser beam for processing can achieve higher processing efficiency, which not only improves efficiency and reduces costs, but also processes smaller and denser micro-holes.

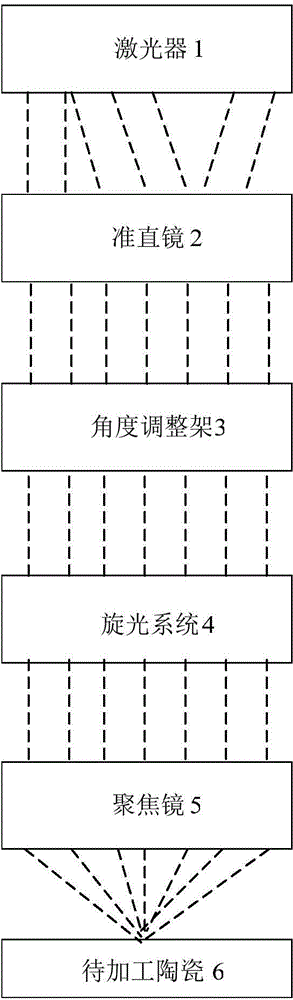

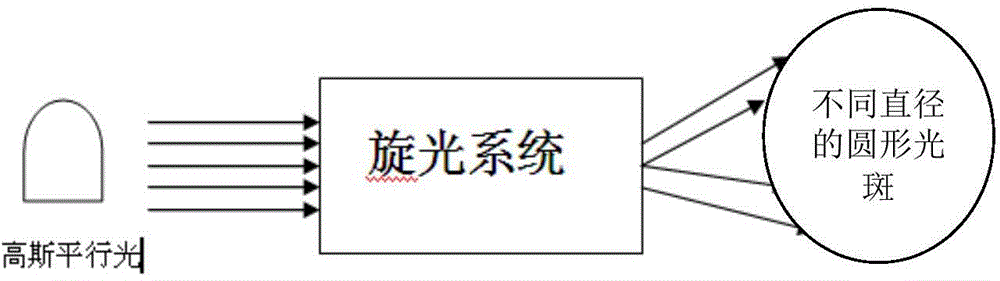

[0025] like figure 1 As shown, the device for fiber laser processing alumina ceramics includes a laser 1, a collimating mirror 2, an angle adjustment foot 3, an optical rotation system 4, and a focusing mirror 5 arranged sequentially along the optical path. The laser 1 is a 1064nm infrared fiber QCW laser, and the optical rotation system 4 Installed under the angle adjustment frame 3, the optical rotation system 4 includes two wedge-shaped lenses, wherein the two sides of each wedge-shaped lens are flat and inclined, the plane of the two wedge-shaped lenses faces outward, and the inclined faces inward, fixed by mechanical components The position of the lens is driven by the motor to rotate the belt fixed on the lens. After changing the corresponding parameters, the lens presents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com