Method for producing coated steel sheet

A manufacturing method and technology for coating steel plates, applied to the surface coating liquid device, coating, metal material coating process, etc., can solve the problem of coating film damage, core material magnetic property damage, unavoidable cost increase, etc. problems, to achieve the effect of preventing uneven coating and preventing flash rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

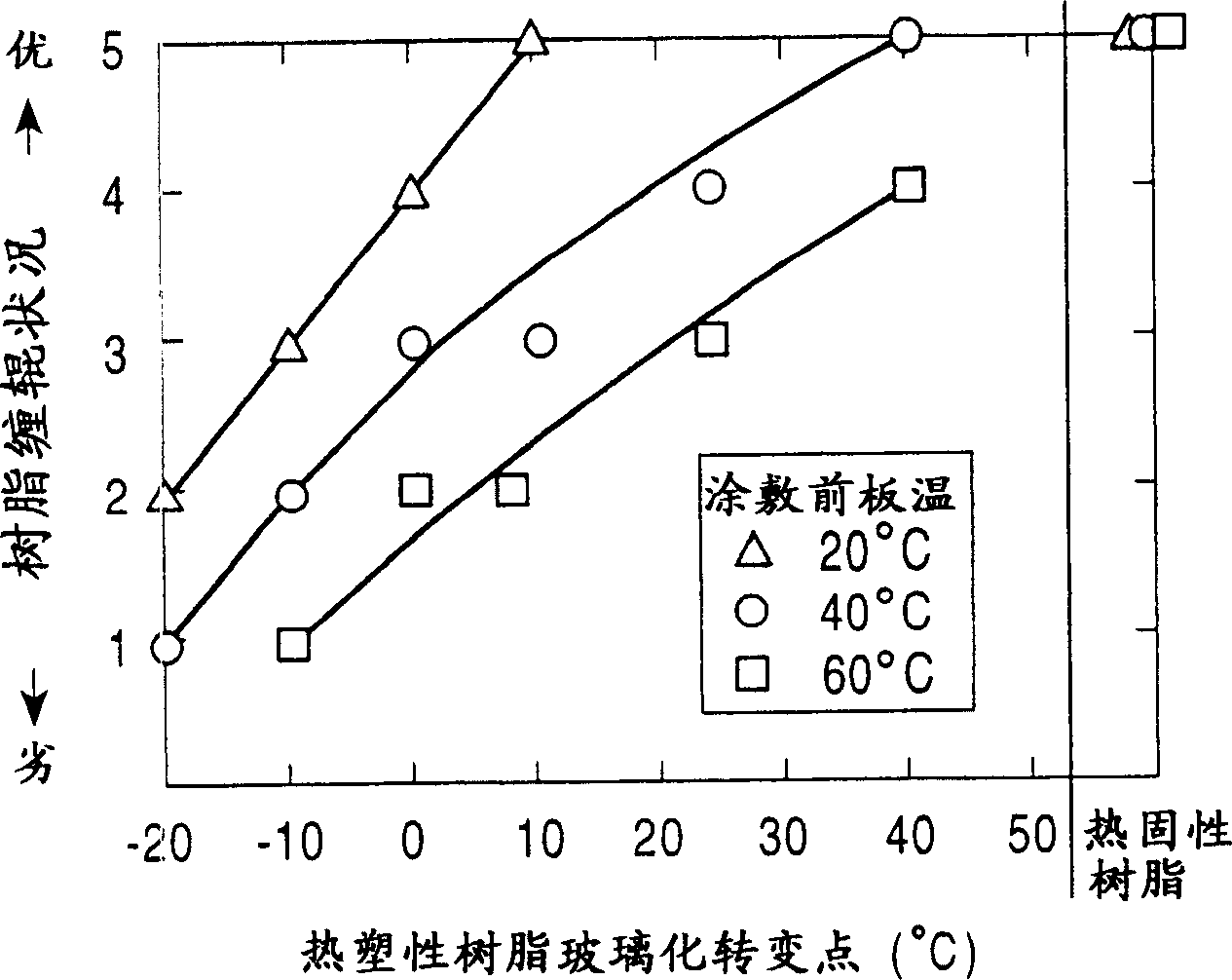

[0181] The raw material steel for cold-rolled steel sheets is smelted, hot-rolled, and then annealed for hot-rolled sheets if necessary. Then implement cold rolling to make a cold-rolled steel strip with a thickness of 0.5mm, a width of 1m, and Ra0.3μm, and then 2 :N 2 =30:70 atmosphere at 900°C for annealing. The water-based coating liquid having the composition shown in Table 6 was coated on each of the annealed raw steel plates. The conditions of coating, drying and baking are shown in Table 7 together with the evaluation of the obtained products. Coating film thickness (average dry area weight on one side) is specified as 0.1-6g / m 2 . The area weight was adjusted by changing the concentration of the coating solution (from 0.5% by mass to 30% by mass).

[0182] Here, the composition of the steel sheet is: C: 0.012% by mass, Si: 0.009% by mass, Mn: 0.14% by mass, Al: 0.032% by mass, other minor elements, and the balance iron.

[0183] The presence or absence of resin e...

Embodiment 2

[0192] According to the usual method, that is, the steel slabs with the specified components are subjected to the steps of hot rolling-hot-rolled sheet annealing-cold rolling-intermediate annealing-cold rolling-final annealing in the above order, and the steel sheet containing Si: 0.35% by mass, Al: 0.001 Mass % and Mn: 0.1 mass %, the balance is Fe and unavoidable impurities, an isotropic electrical steel sheet (raw material steel sheet) having a thickness of 0.5 mm and an Ra of 0.4 μm. Here, the attained temperatures in the hot-rolled sheet annealing, intermediate annealing, and final annealing were set to 1000°C, 900°C, and 1000°C, respectively.

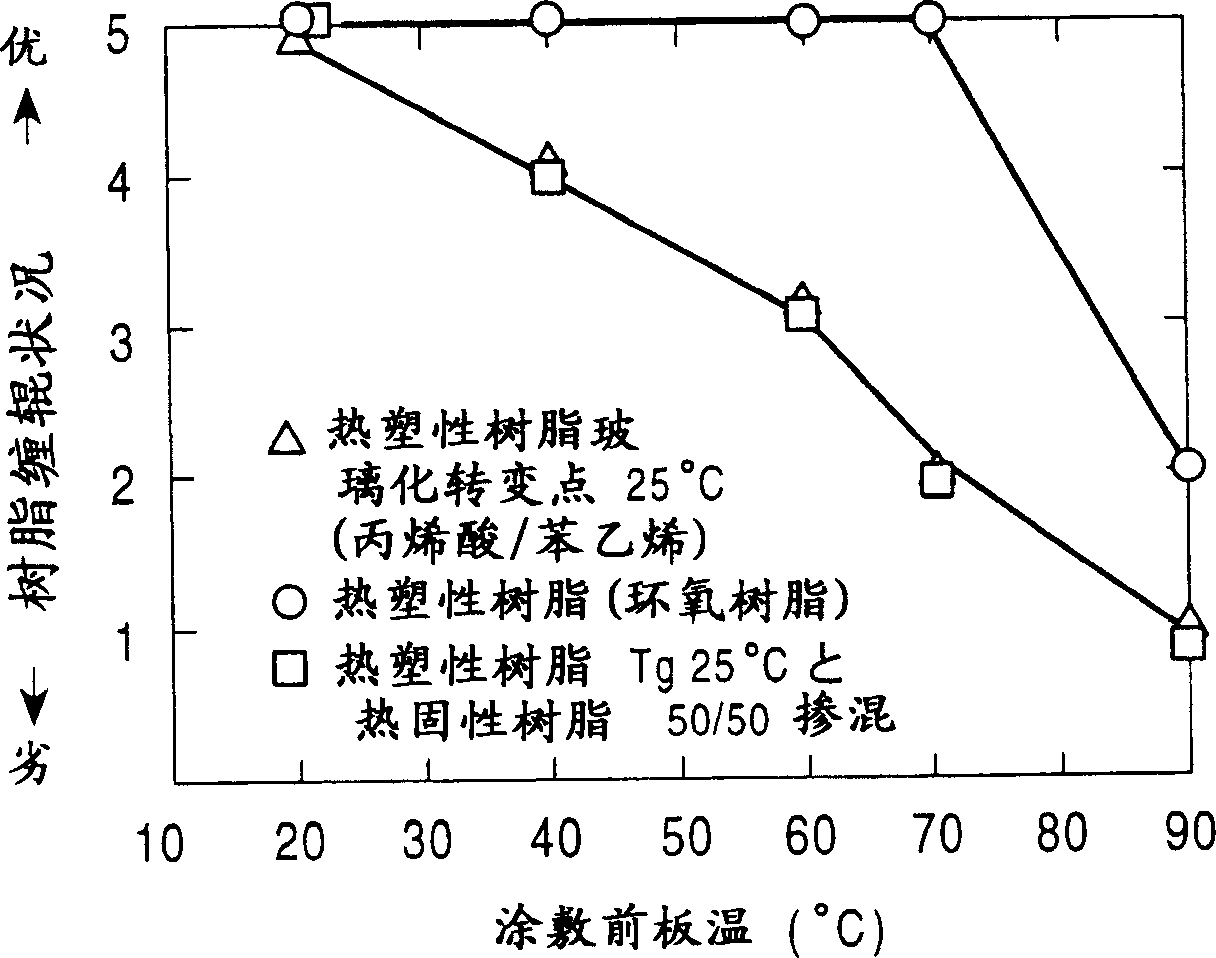

[0193]On the surface (both sides) of the above-mentioned electrical steel sheet cooled to 30°C, a roll coater is used to apply a water-based coating solution in which magnesium dichromate: 50% by mass, acrylic acid is mixed in terms of solute components and dispersoid components. / Styrene resin emulsion (particle diameter 200nm, ...

Embodiment 3

[0211] Using the same procedure as in Example 1, a steel sheet with a plate thickness of 0.35 mm and a Ra of 0.3 μm was obtained, which contained Si: 3.0% by mass, Al: 0.001% by mass, and Mn: 0.1% by mass, with the balance being Fe and unavoidable impurities. Electromagnetic steel sheet (billet steel sheet).

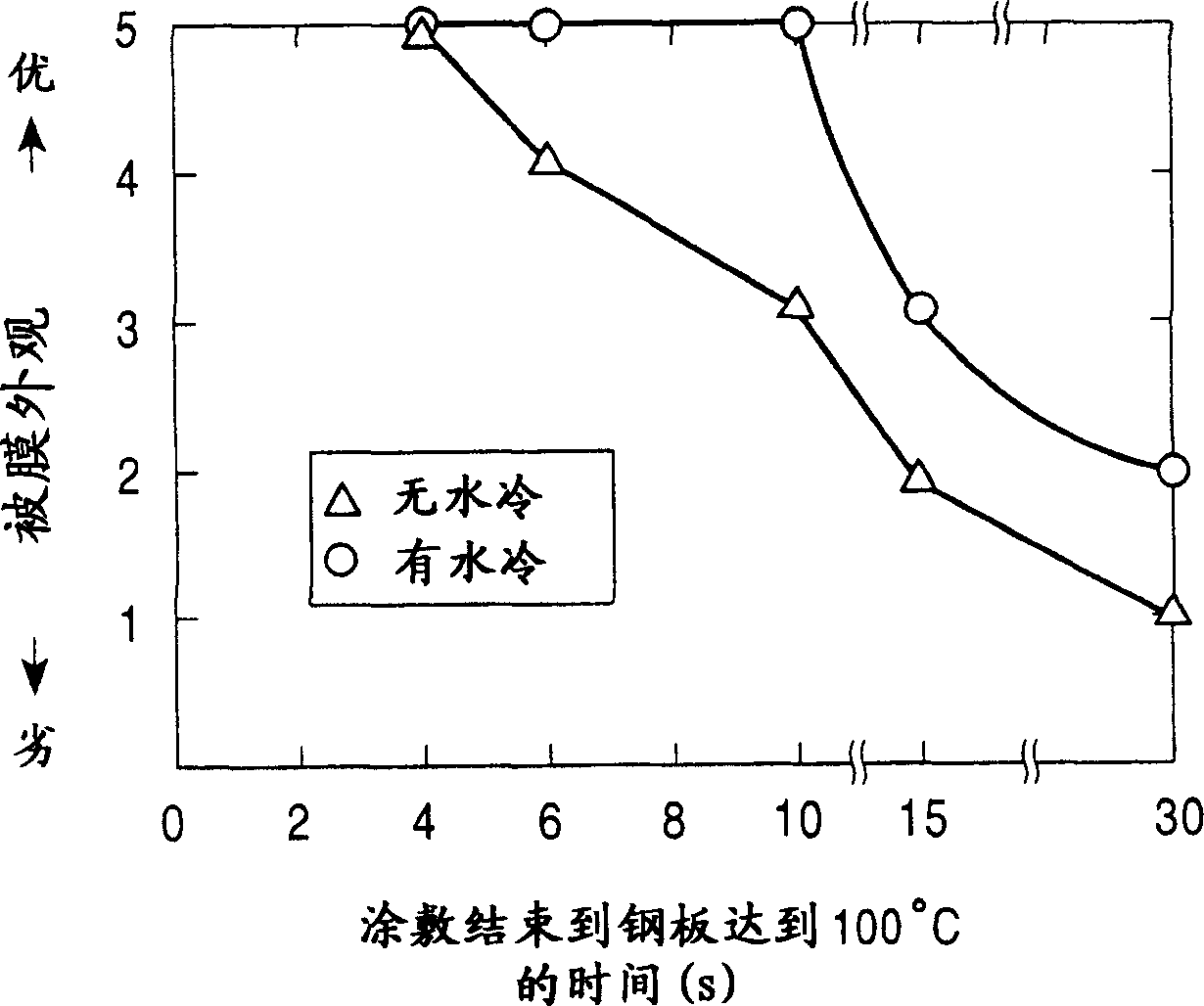

[0212] On the surface (both sides) of the above-mentioned electrical steel sheet cooled to 40°C, a roll coater was used to apply a water-based coating solution in which colloidal silica: 60% by mass, Dispersible epoxy resin (particle diameter: 500 nm): 40% by mass (expressed by mass ratio, water: the above-mentioned solute·dispersate component = 95:5). Thereafter, the induction heating method or the hot air furnace heating method are used to perform drying and baking treatment to reach a plate temperature of 200°C respectively, and an insulating coating film with an average surface weight of 0.8g / m2 is coated on the basis of dry area weight. Other coating conditions are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com