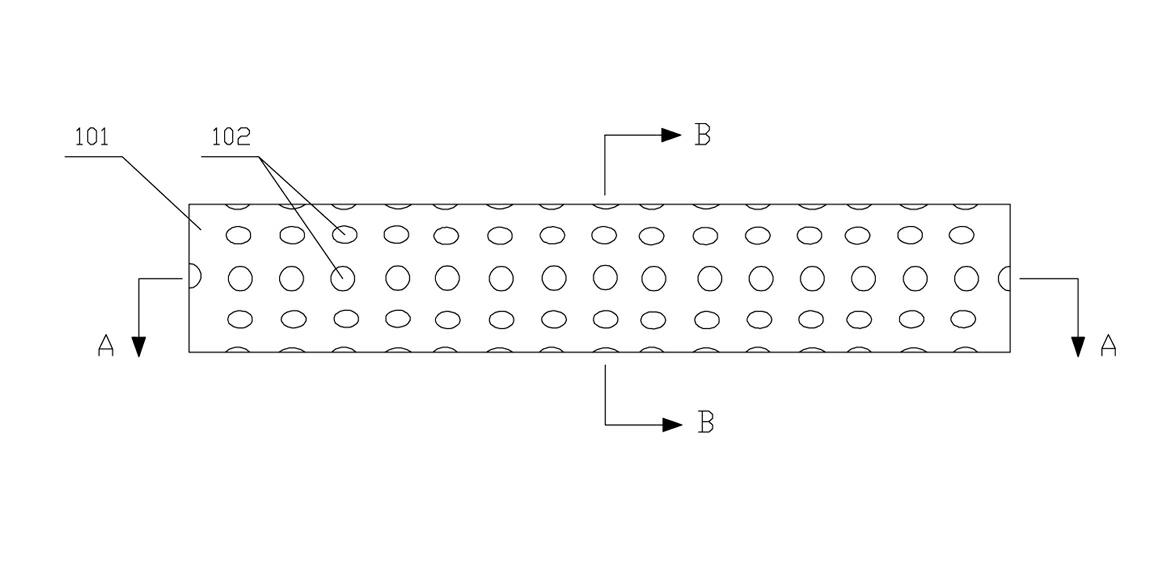

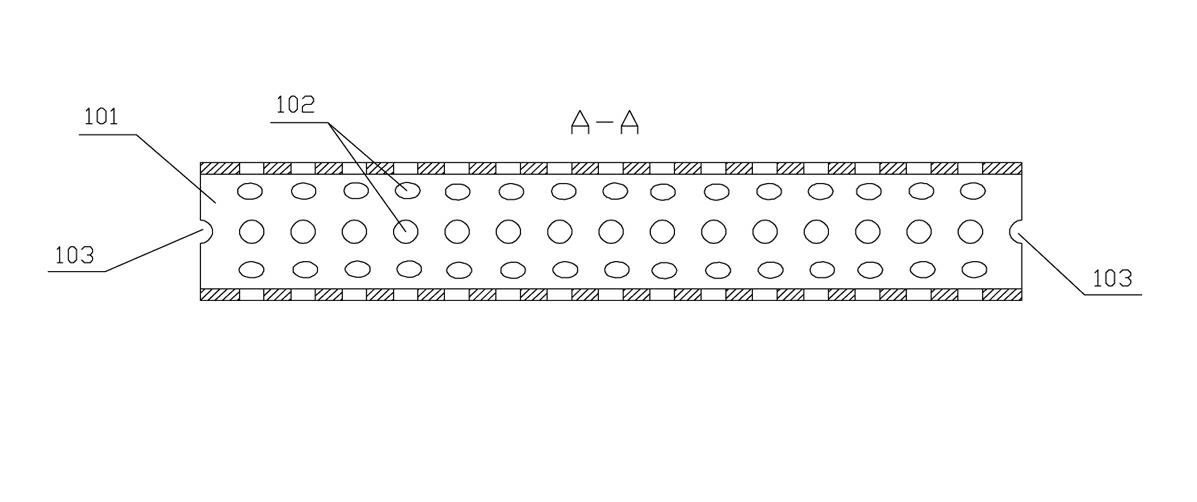

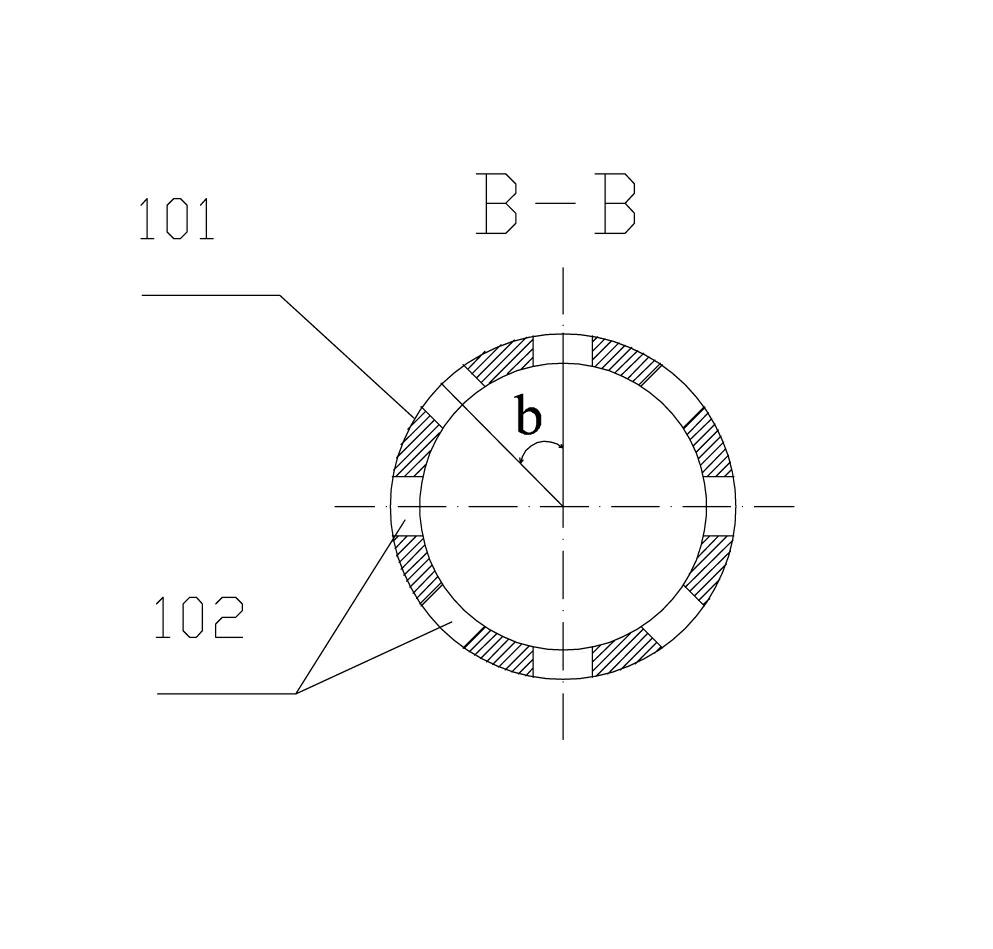

Punching die for drainage holes of stainless steel tubes

A technology of stainless steel pipes and punching dies, which is applied in the field of parts processing equipment, can solve the problems of low efficiency, low processing accuracy, and backward processing methods, and achieve the effects of less manual operations, high production accuracy, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] combined with Figure 4 To attach Figure 8 , a punching die for stainless steel pipe row holes, which includes an upper die and a lower die, the upper die includes a die handle 201, an upper template 202, a backing plate 203, a fixed plate 207 and a plurality of side-by-side punches 205, and a fixed plate 207 On the upper end surface of the upper end, a backing plate 203, an upper template 202 and a mold handle 201 are installed in sequence from bottom to top, and a plurality of side-by-side punches 205 are embedded in the fixed plate 207; the lower mold includes a product positioning device 301, a left positioning plate 320 , the right positioning plate 303, the lower fixing plate 317 and the base plate 316, the upper end surface of the base plate 316 is equipped with a lower fixing plate 317, the left side of the lower fixing plate 317 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com