Bamboo perforating machine

A punching machine, bamboo and wood technology, applied in the direction of fixed drilling machines, etc., can solve the problems of poor positioning ability of bamboo strips, and achieve the effects of precise drilling, easy implementation, and high accuracy of punching positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

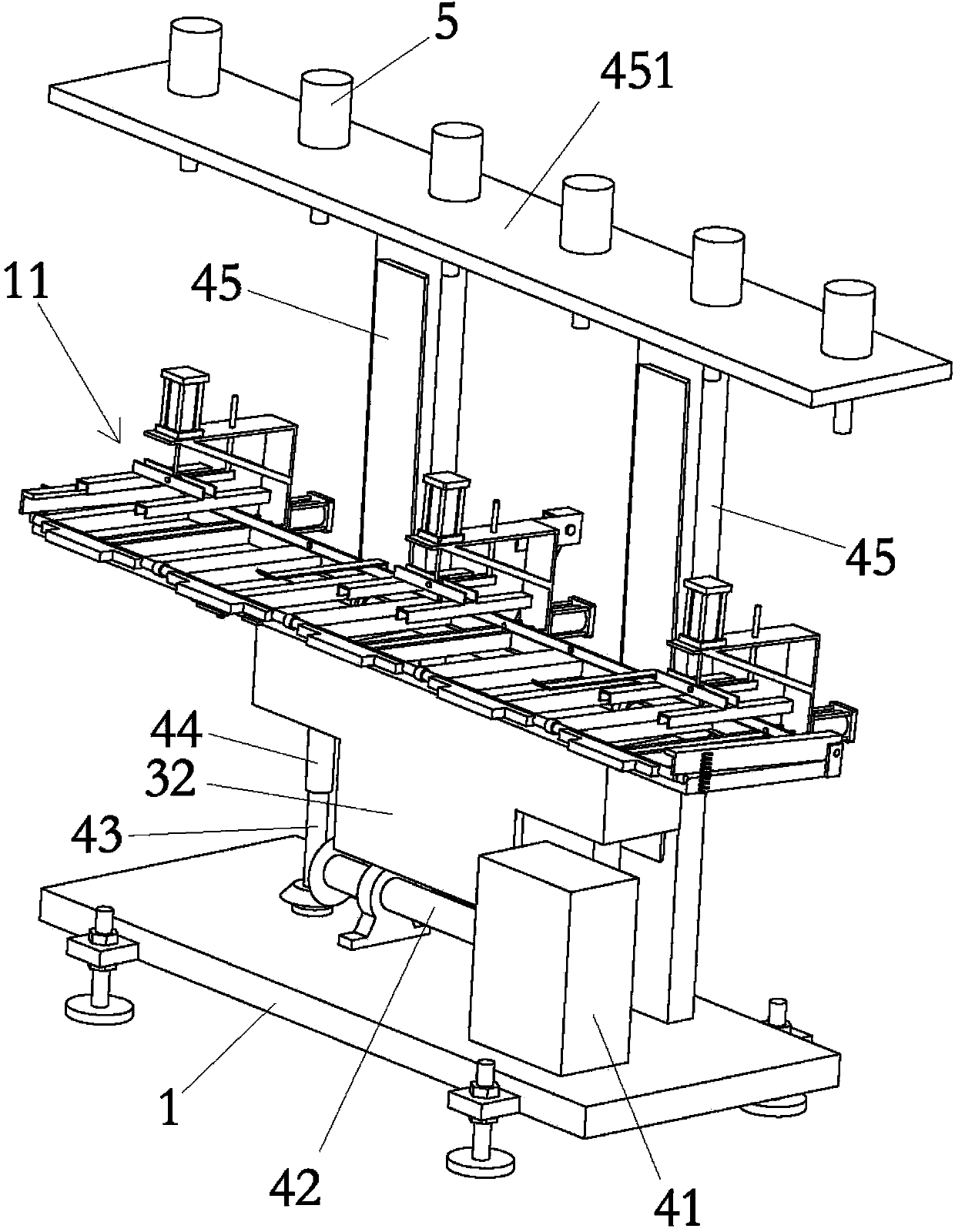

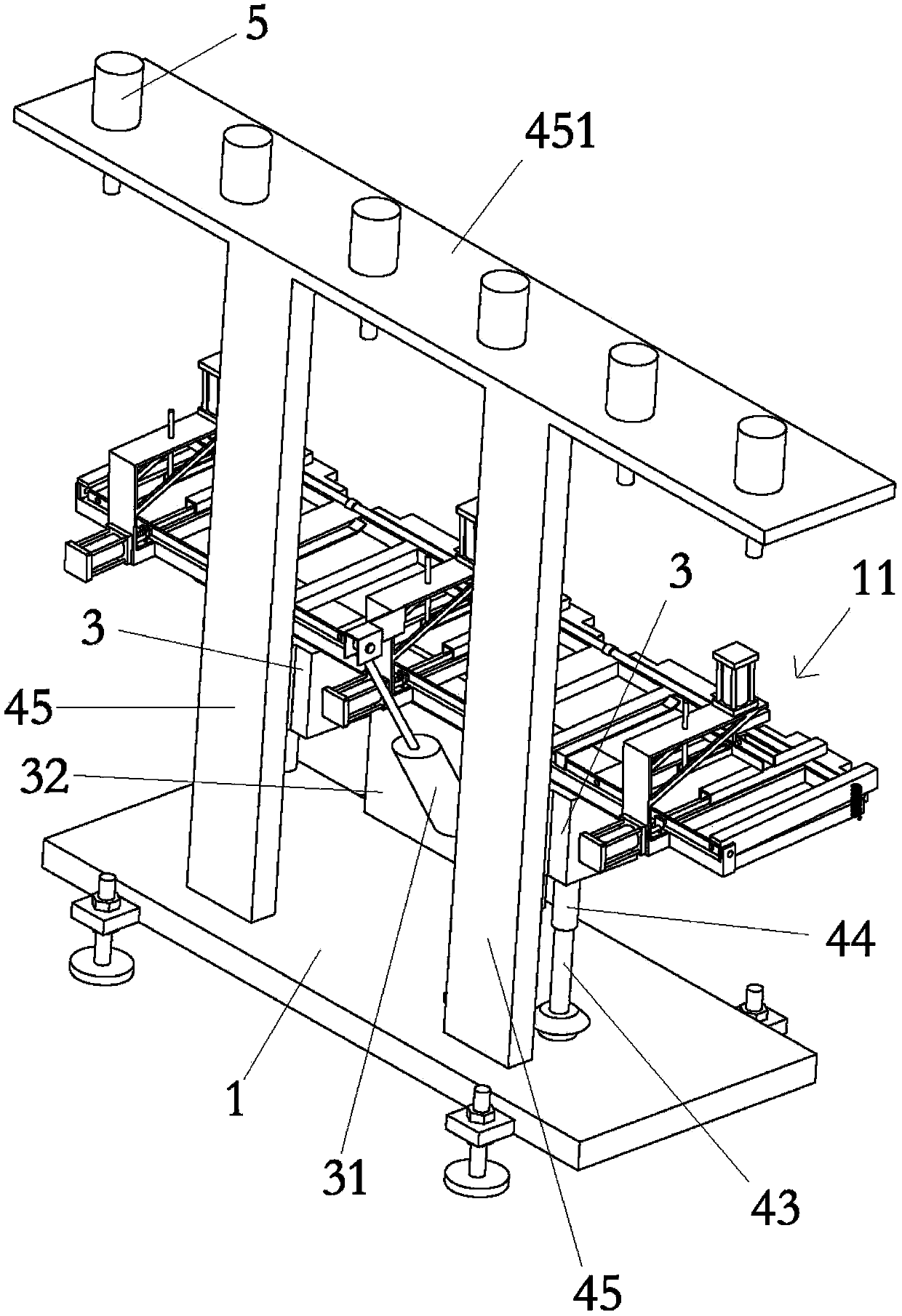

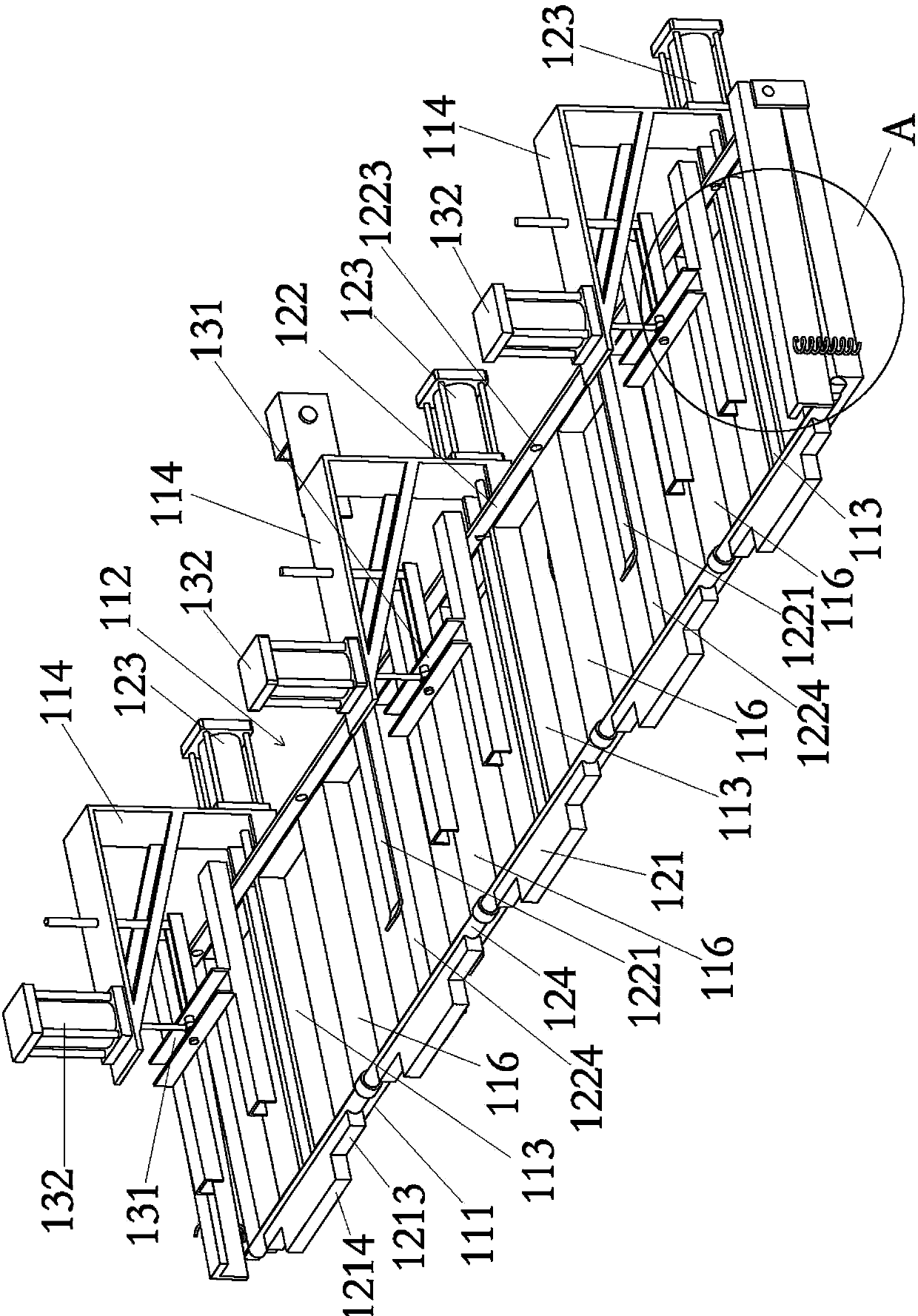

[0038] Embodiment: A kind of bamboo and wood punching machine comprises base 2, and base 2 is provided with elevating mechanism, and elevating mechanism comprises the driving motor 41 that is arranged on base 2, and base 2 is also provided with the bearing that distributes along the length direction of base 2 The drive shaft 42 connected to the output shaft of the drive motor 41 is connected to the two bearings for rotation. The drive shaft 42 is respectively connected to a screw rod 43 through a bevel gear assembly, and each screw rod 43 is screwed with a guide sleeve. 44. The two guide sleeves 44 are respectively rotatably connected with the lifting platform 3, and the lifting platform 3 should be relatively fixed with the guide sleeve 44 in the longitudinal direction at the same time; Also be provided with two guide rails 45 corresponding to lift platform 3, each lift platform 3 is slidably connected with corresponding guide rail 45; Have dovetail groove on lift platform 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com