Material surface continuous punching device

A technology of punching device and arc rod, which is applied in the direction of wood processing equipment, metal processing, manufacturing tools, etc., can solve the problems of large volume and high cost, and achieve the effect of low manual intervention, convenient operation, and fast uniform punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

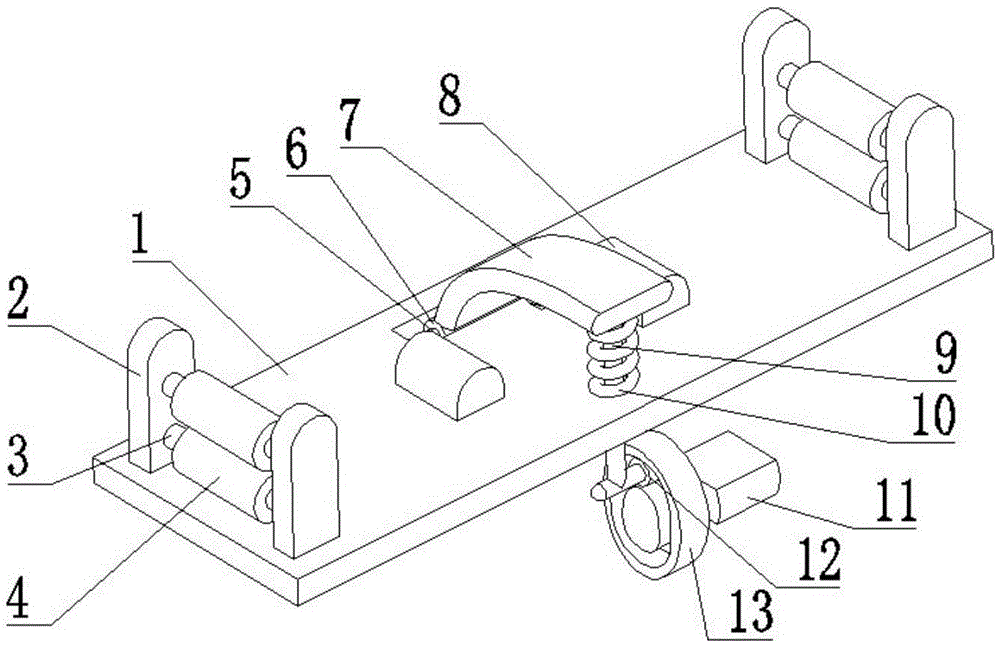

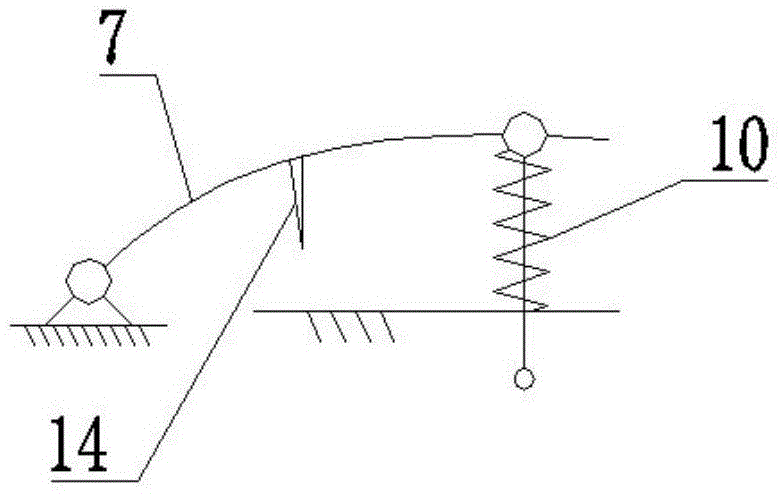

[0017] refer to figure 1 and figure 2 , a material surface continuous punching device of the present invention, comprising a base 1, a support rod 2, a fixed shaft 5, a roller shaft 6, an arc rod 7, a pull rod 9, a spring 10, a roller 12, a grooved cam 13 and a punching hole Nail 14, a plurality of support rods 2 are installed on the base 1, and the support rods 2 are connected by a rotating shaft 3, and a roller 4 is installed on the rotating shaft 3; grooves are arranged in the base 1, and grooves are installed on the grooves. Fixed shaft 5, roller 6 is installed on fixed shaft 5, and roller 4 is fixedly connected with arc-shaped rod 7; Said arc-shaped rod 7 is hingedly connected with pull rod 9, and spring 10 is inserted in pull rod 9, and the two ends of spring 10 The arc rod 7 and the base 1 are fixedly connected respectively; the bottom end of the pull rod 9 is fixedly connected with a section of a cross bar, and a roller 12 is installed on the cross bar; the roller 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com