Rotor disc boss type periodic pressure wave generating device

A technology for generating devices and bosses, which is applied to engine components, blade support components, machines/engines, etc., and can solve the problems of unsatisfactory gas turbine heat exchange, cooling effect, large pressure fluctuation loss, and uncontrollable pressure fluctuation characteristics. , to achieve the effect of good practical effect, good adaptability and wide range of engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

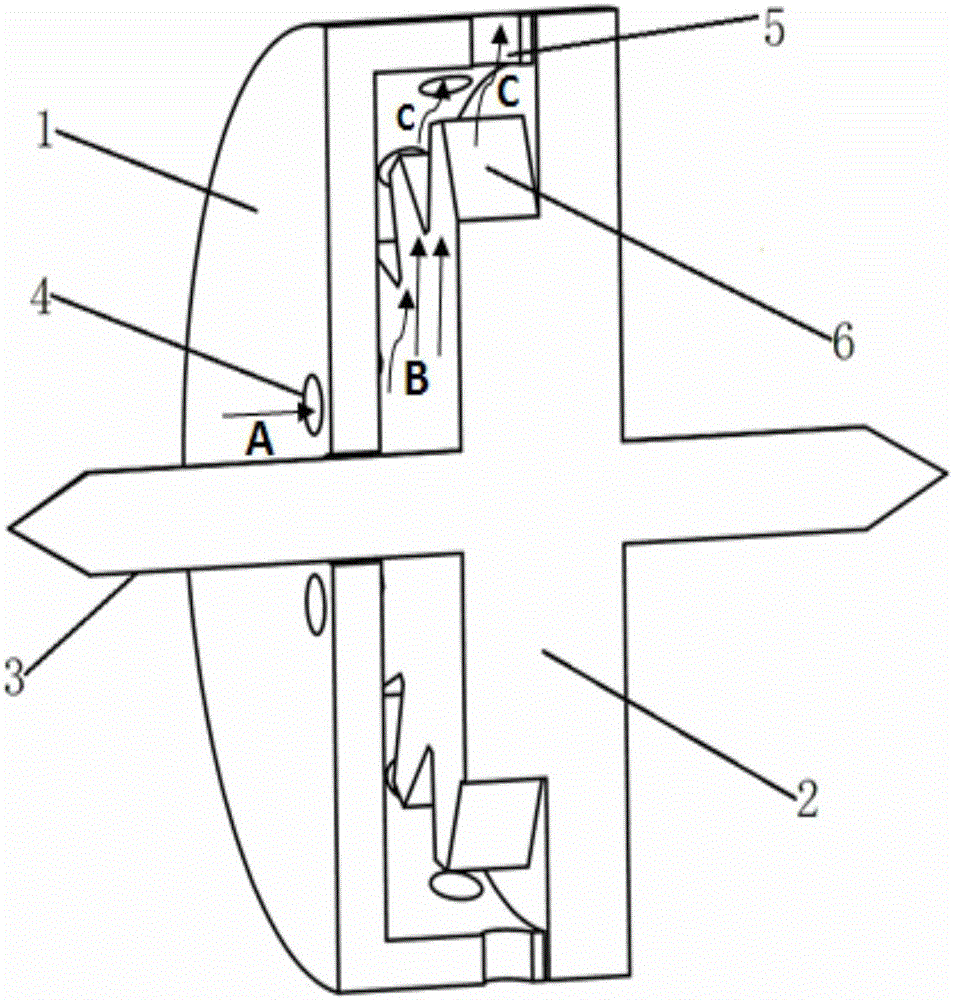

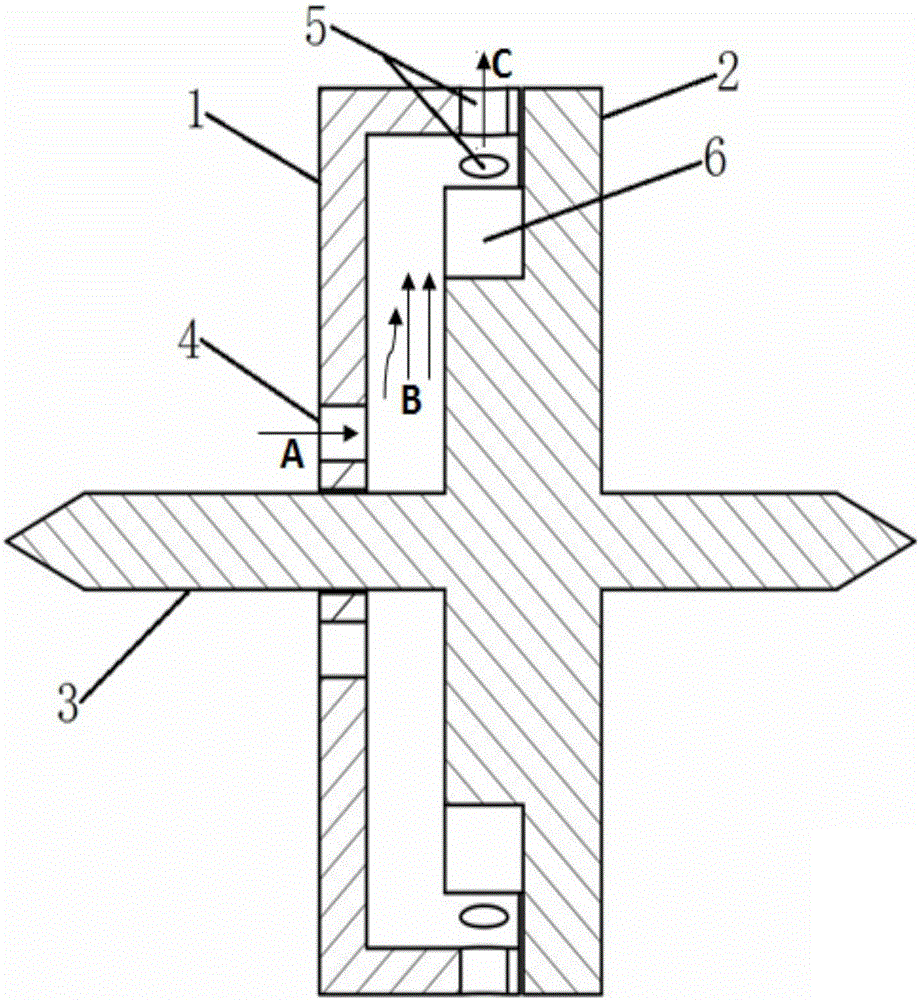

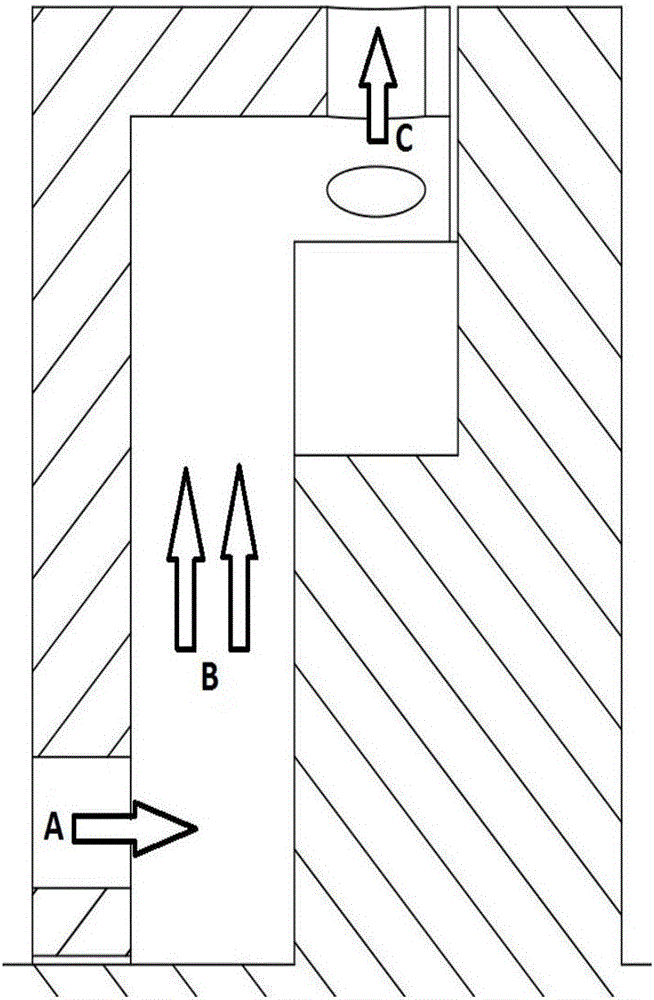

Embodiment 1

[0030]In this embodiment, the diameter of the stator plate of the boss-type periodic pressure wave generating device of the rotor is 490 mm, and the axial width is 130 mm; wherein, the distance between the center of the air inlet hole and the center of the axis is 50 mm, and the diameter of the air inlet hole is 25 mm. In the example, there are 6 air inlet holes distributed evenly in the circumferential direction, the length of the air inlet holes is 30mm; the length of the air outlet holes is 25mm, and the diameter is 5mm; in this embodiment, there are 16 air outlet holes uniformly distributed in the circumferential direction on the side wall of the stator disc. In the rotor disk, the diameter of the rotating shaft is 52mm, the diameter of the protruding part of the rotor disk is 285mm, and the width is 50mm; the diameter of the end surface of the rotor disk is 490mm, and the axial width is 30mm. Among them, the bottom surface of the boss is a curved rectangle, the arc angle θ...

Embodiment 2

[0033] In this embodiment, the diameter of the stator plate of the boss-type periodic pressure wave generating device of the rotor is 490 mm, and the axial width is 130 mm; wherein, the distance between the center of the air inlet hole and the center of the axis is 50 mm, and the diameter of the air inlet hole is 25 mm. In the example, there are 8 air inlet holes on the stator plate and they are uniformly distributed in the circumferential direction. The length of the air inlet holes is 30mm; the length of the air outlet holes is 15mm and the diameter is 10mm; indivual. In the rotor disk, the diameter of the rotating shaft is 52mm, the diameter of the protruding part of the rotor disk is 285mm, and the width is 50mm; the diameter of the end surface of the rotor disk is 490mm, and the axial width is 30mm. Among them, the bottom surface of the boss is a curved rectangle, the arc angle θ is 20°, and the arc length L in the size of the bottom surface is 1 is 49.7mm, and the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com