Patents

Literature

42results about "Powdered engine fuels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

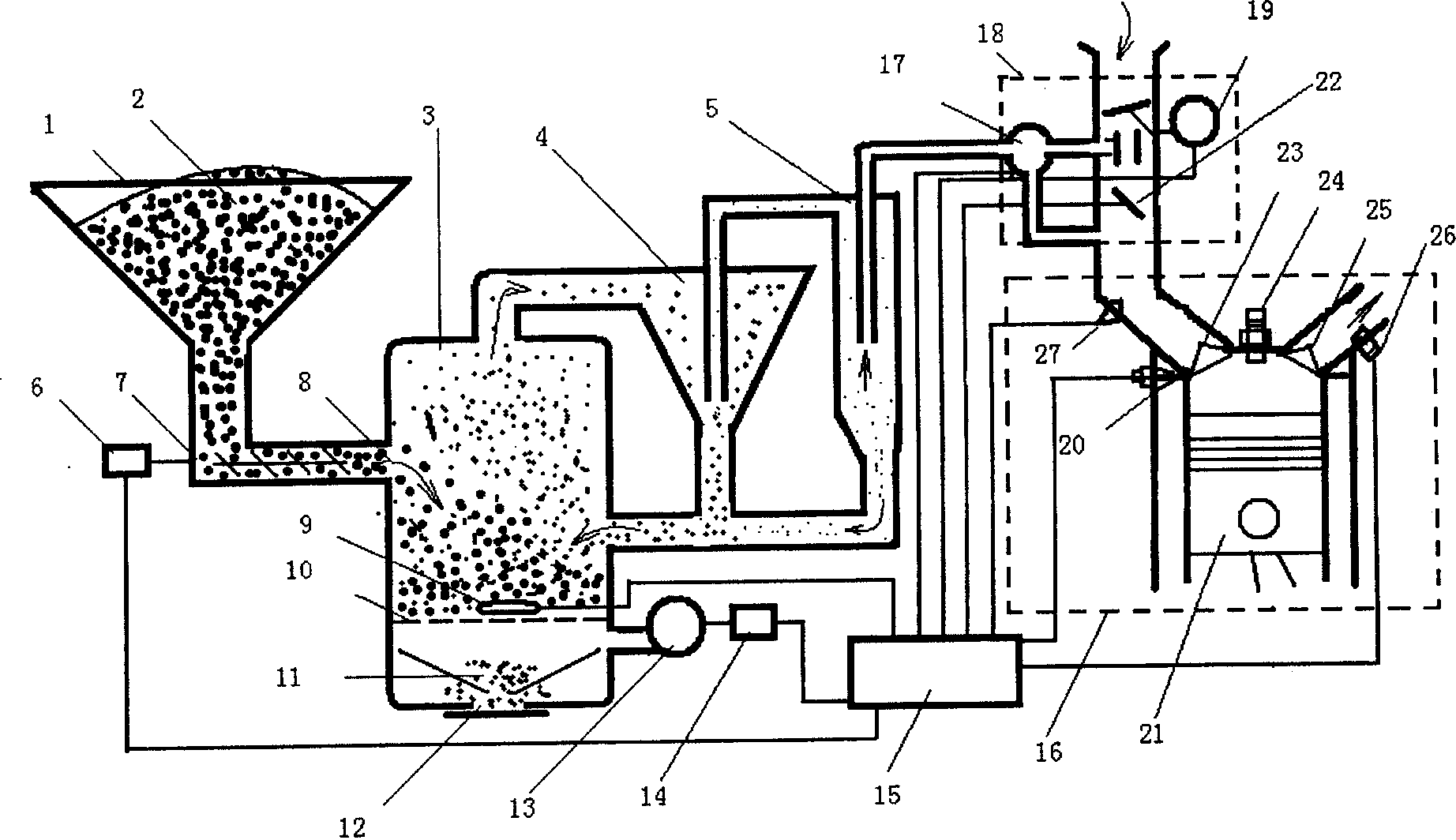

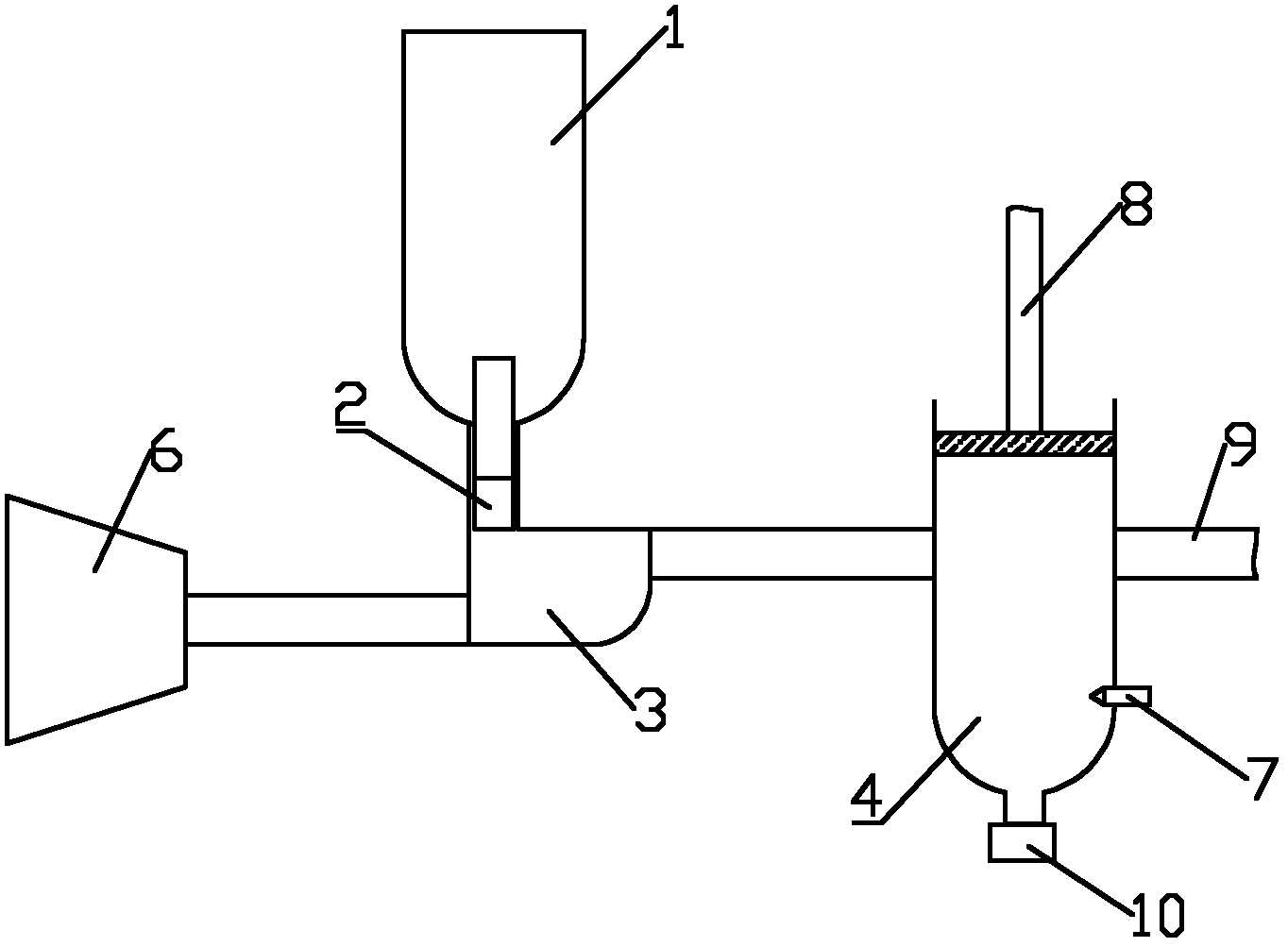

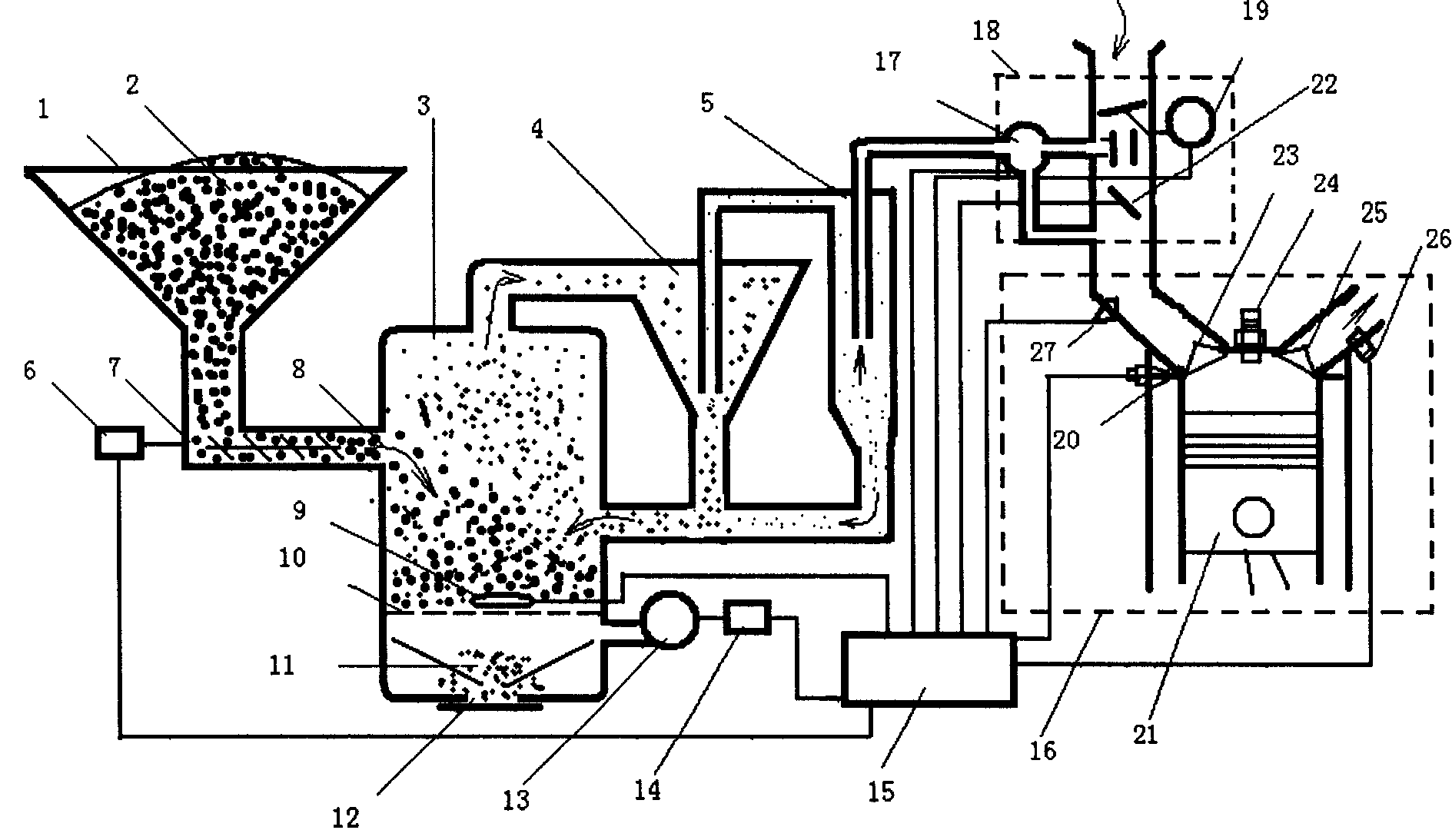

Internal-combustion engine of combustible powder

InactiveCN1916381ARich sourcesSolve the energy crisisInternal combustion piston enginesPowdered engine fuelsInternal combustion engineCoal

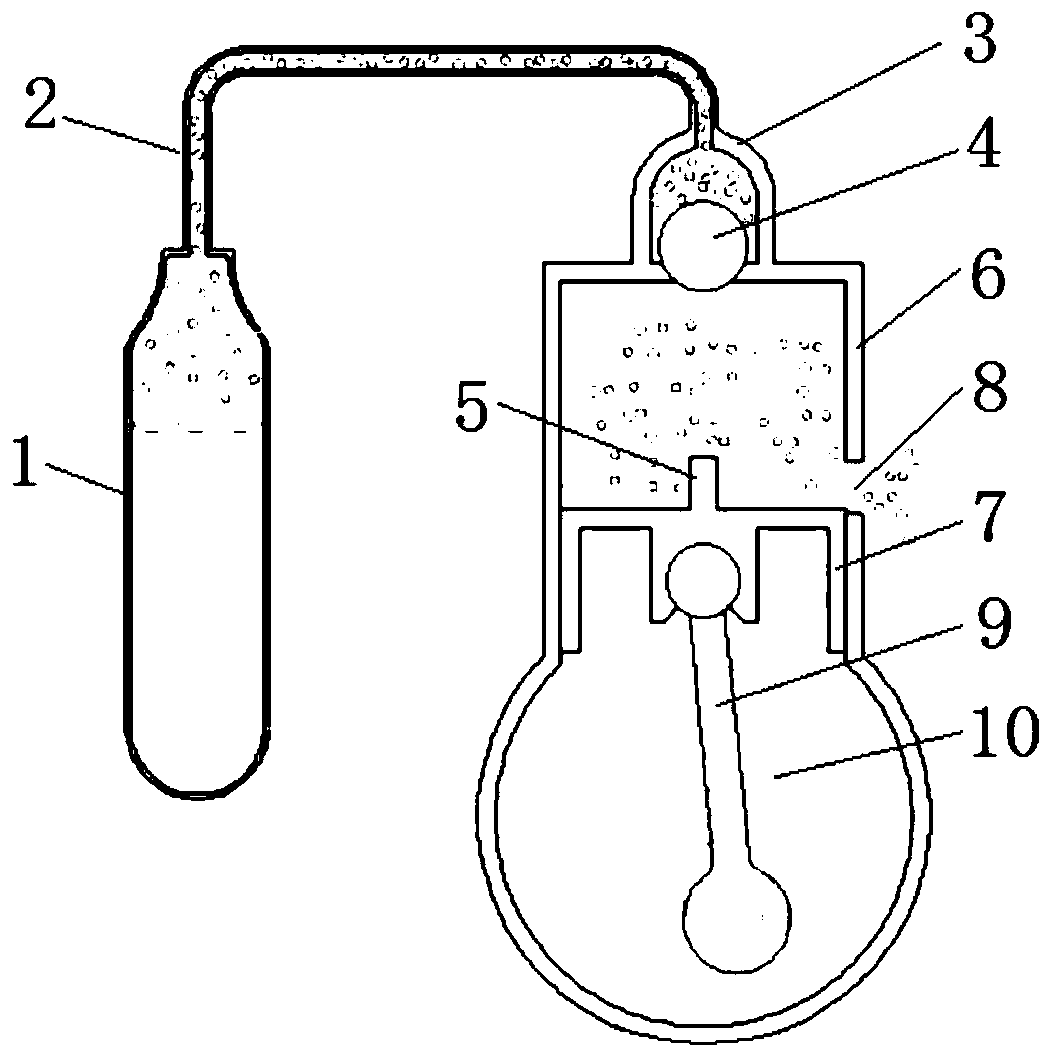

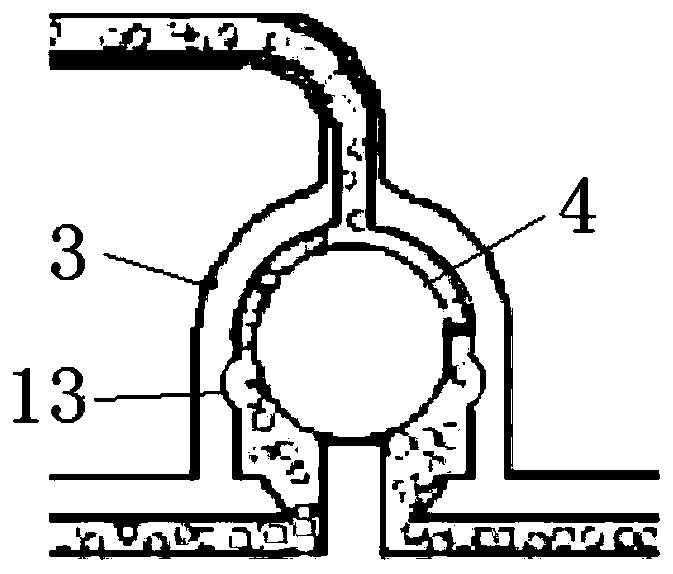

An internal-combustion engine using combustible powder as fuel consists of fuel material preprocessor, mixer, fuel jet and discharging processor. The said combustible powder is prepared from plant residues, coal or combustible wastes and additives.

Owner:陈丽君

Solid fuel internal-combustion engine

InactiveCN101265838ASolve wear and tearSolve corrosiveInternal combustion piston enginesPowdered engine fuelsSolid fuelMechanical energy

The invention relates to a solid fuel diesel, which is an explosive motor burning solid fuel powder (such as plants, coal, etc.), and the performance (including the convenience of fuel employment) is similar to a piston diesel, wherein water is used as working substance to realize the conversion from pressure energy to mechanic energy without a bent axle or a piston; the solid fuel diesel can function as power for engineering machines, vehicles and vessels; the manufacture cost is low; the vibration is low; the efficiency is high; and the service life is long. The theory and structure of the whole machine are introduced in the specification.

Owner:汪伯瑞

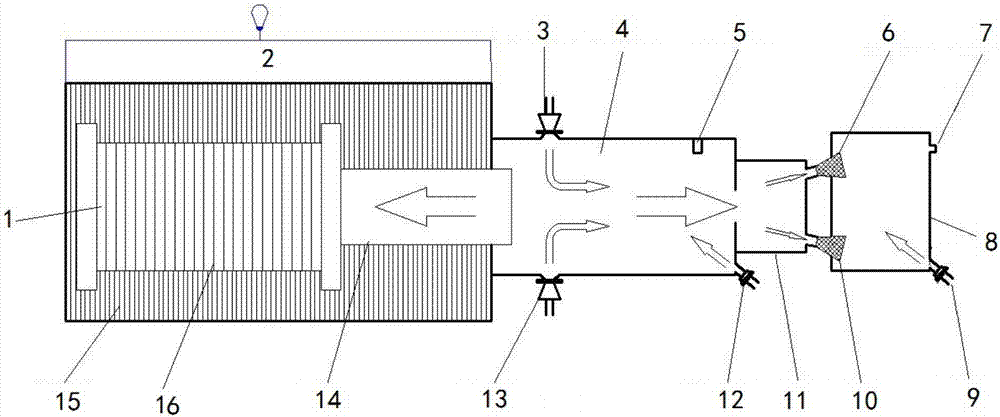

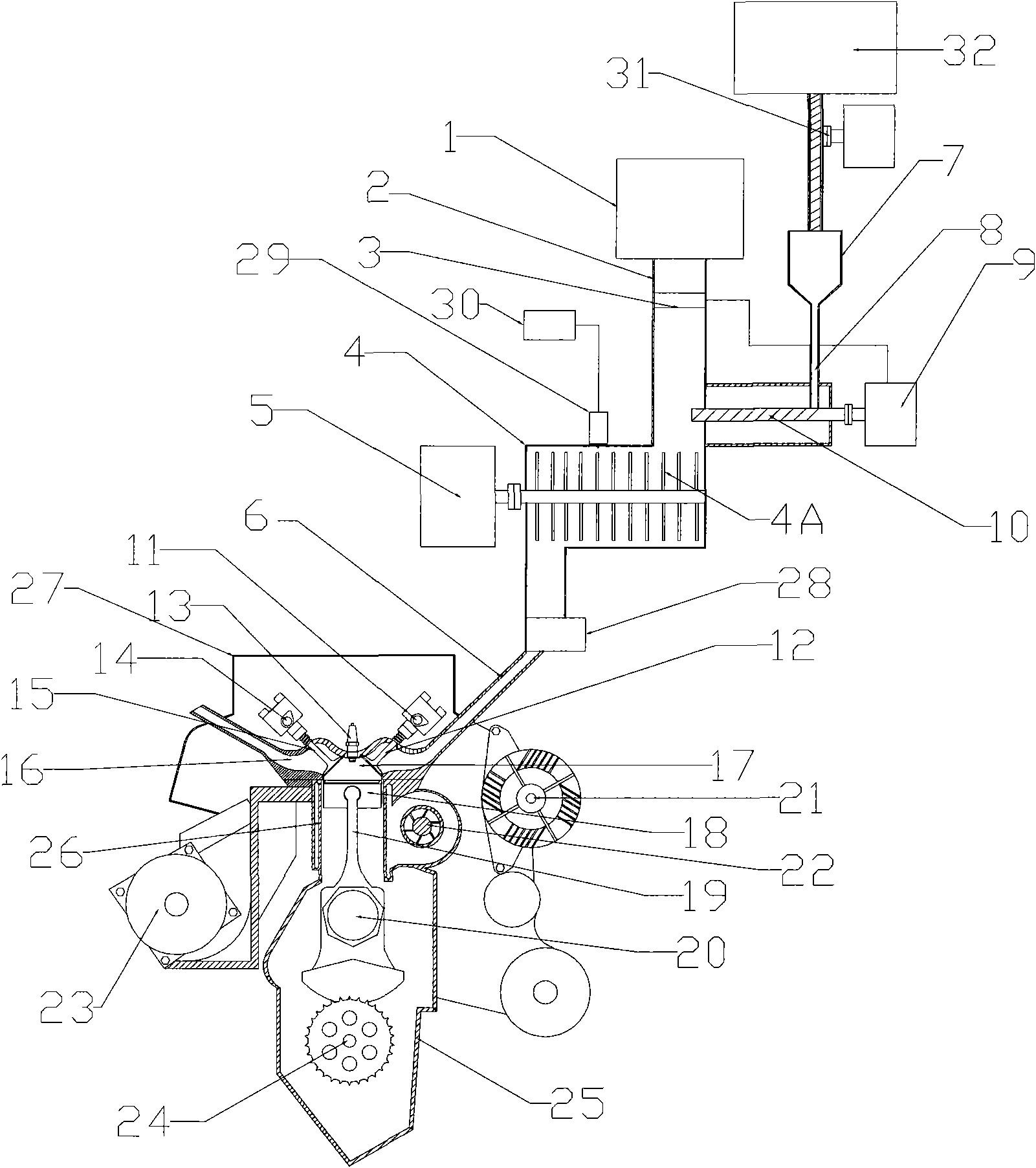

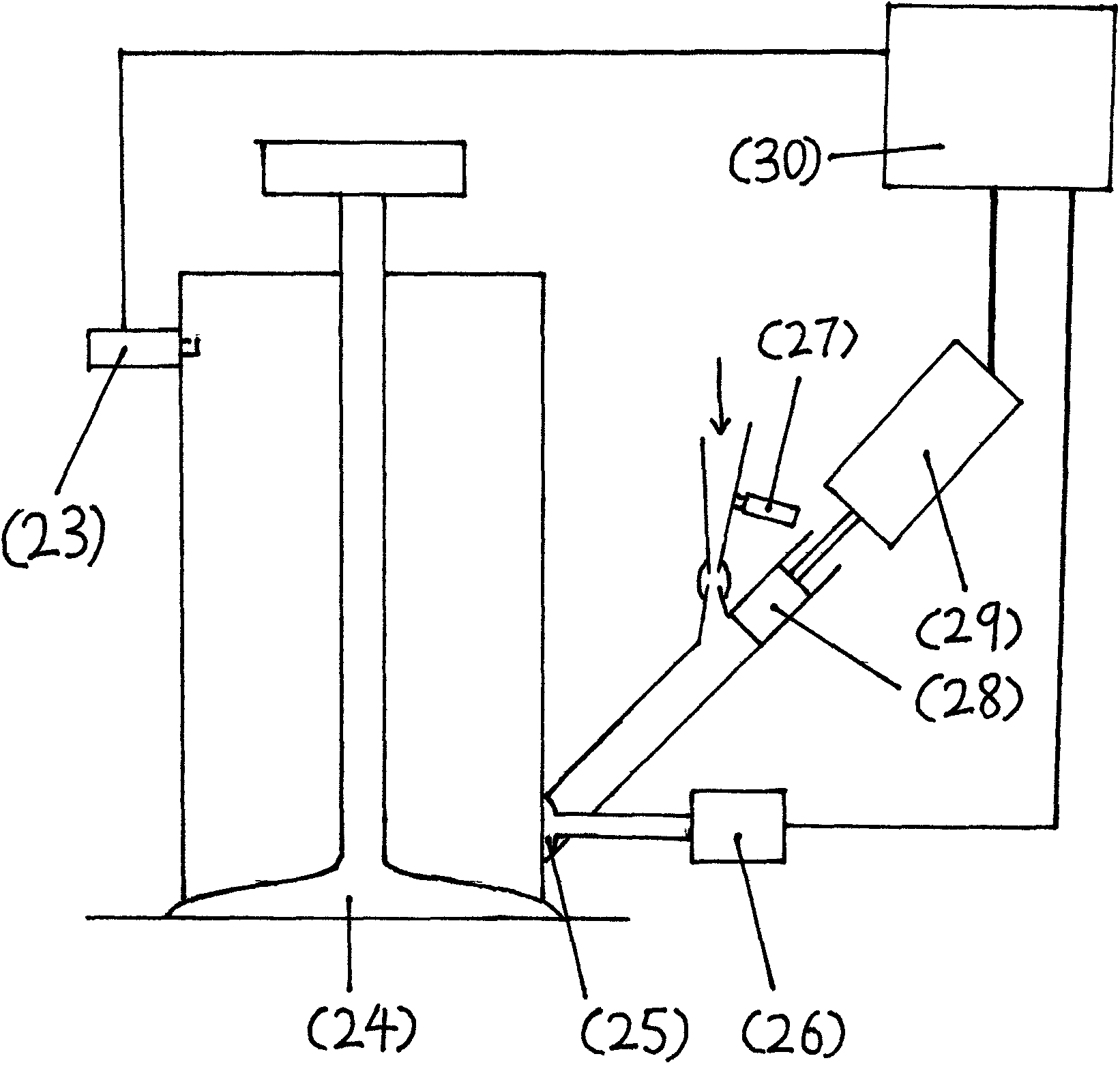

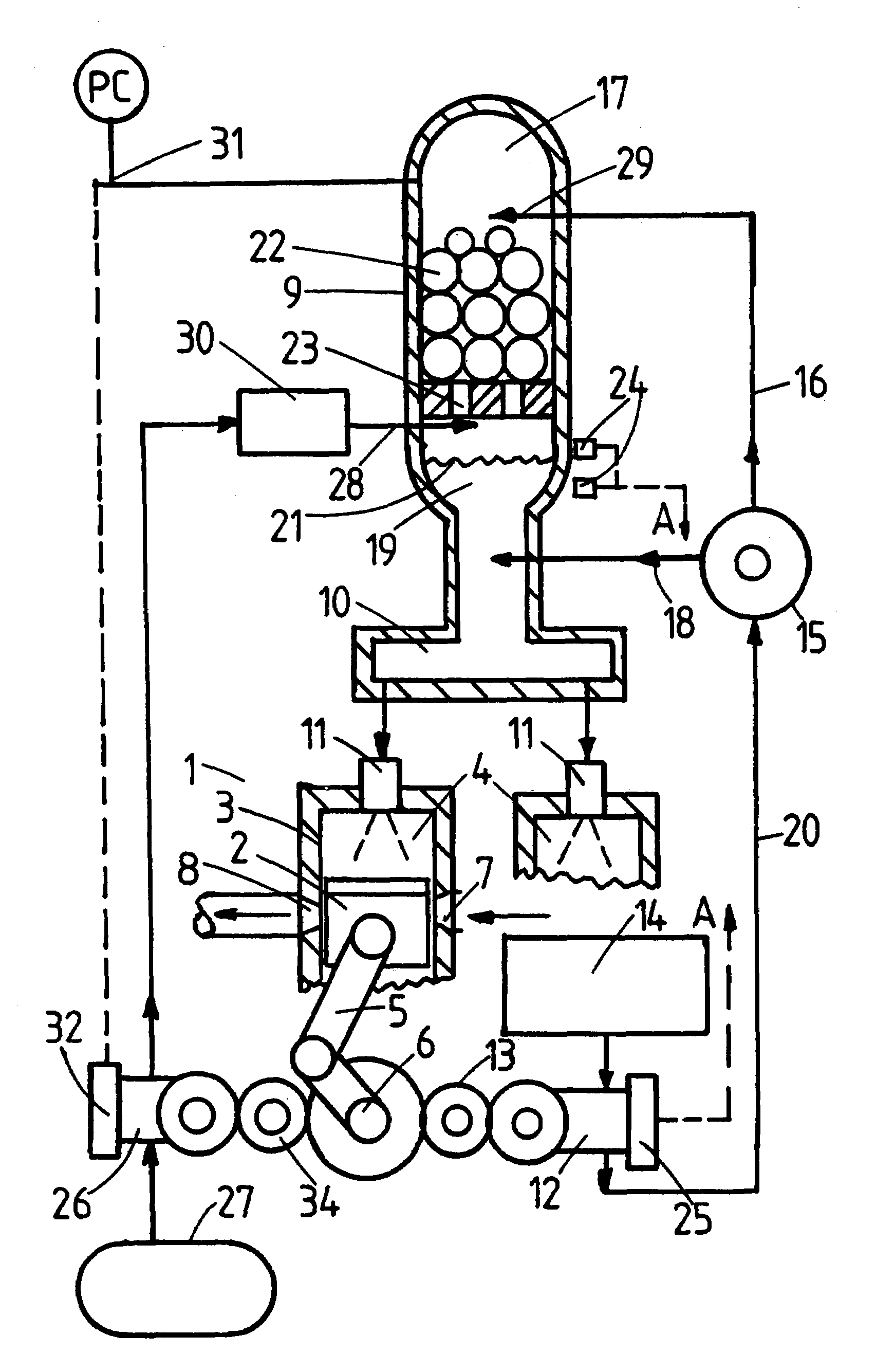

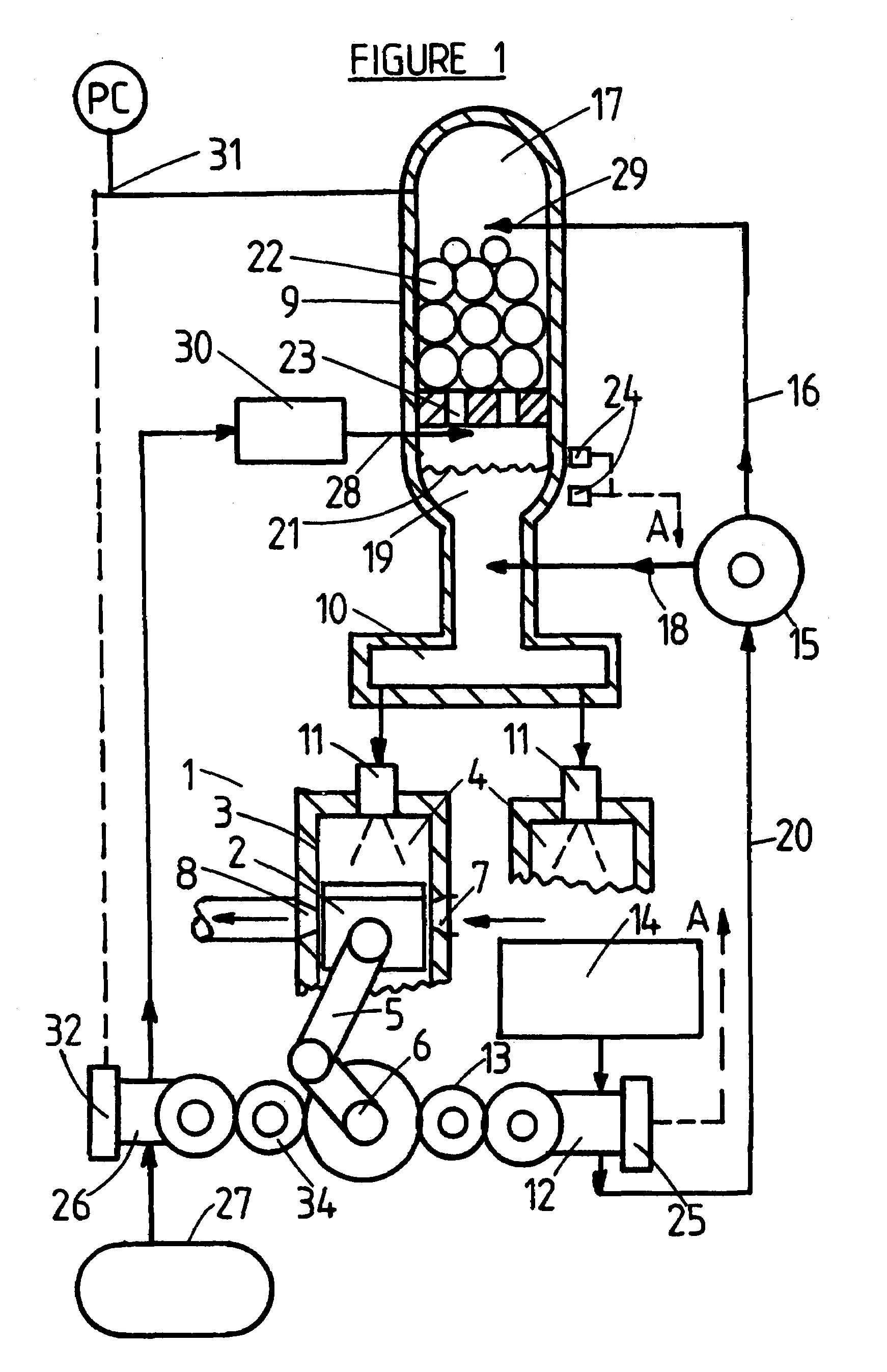

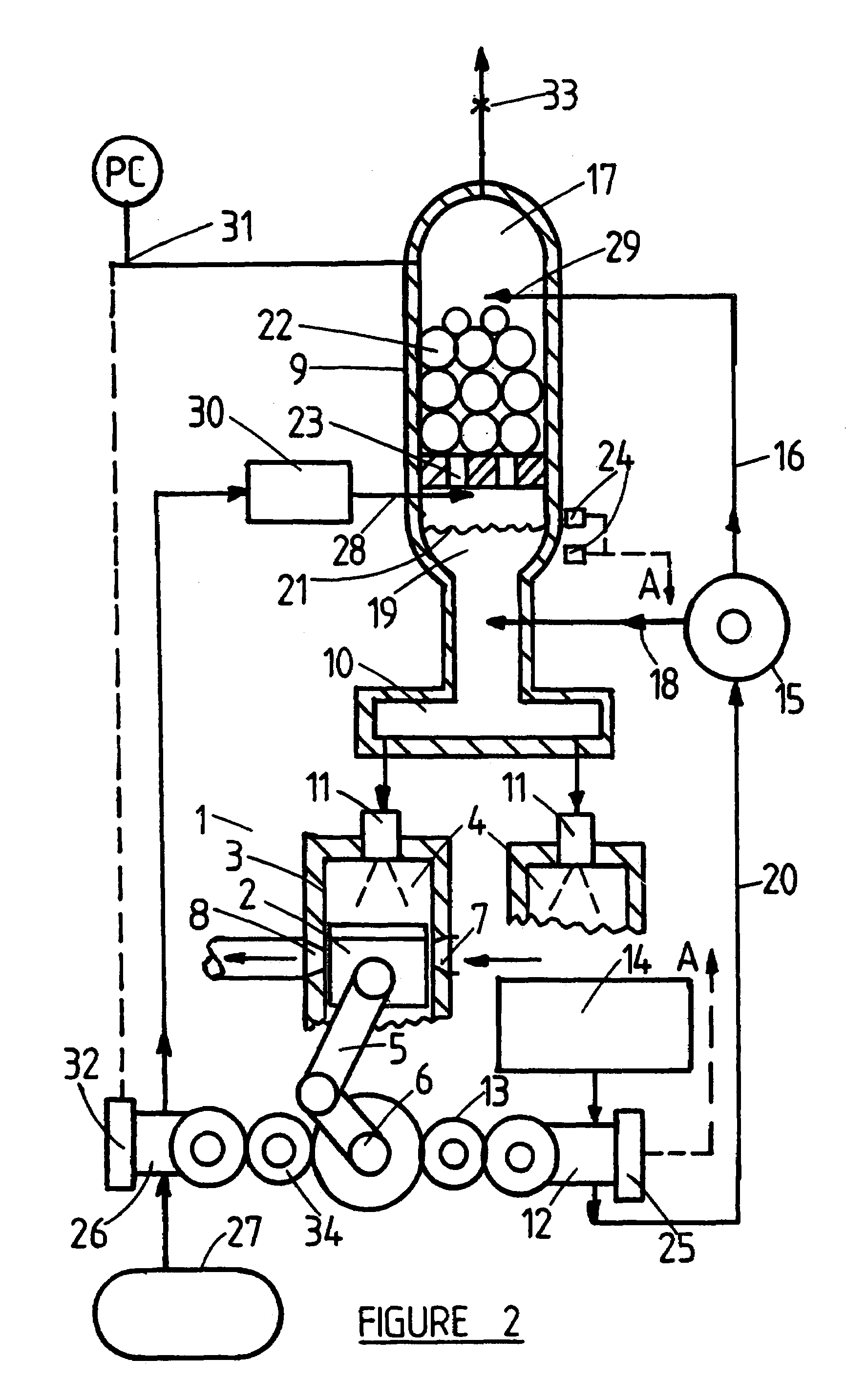

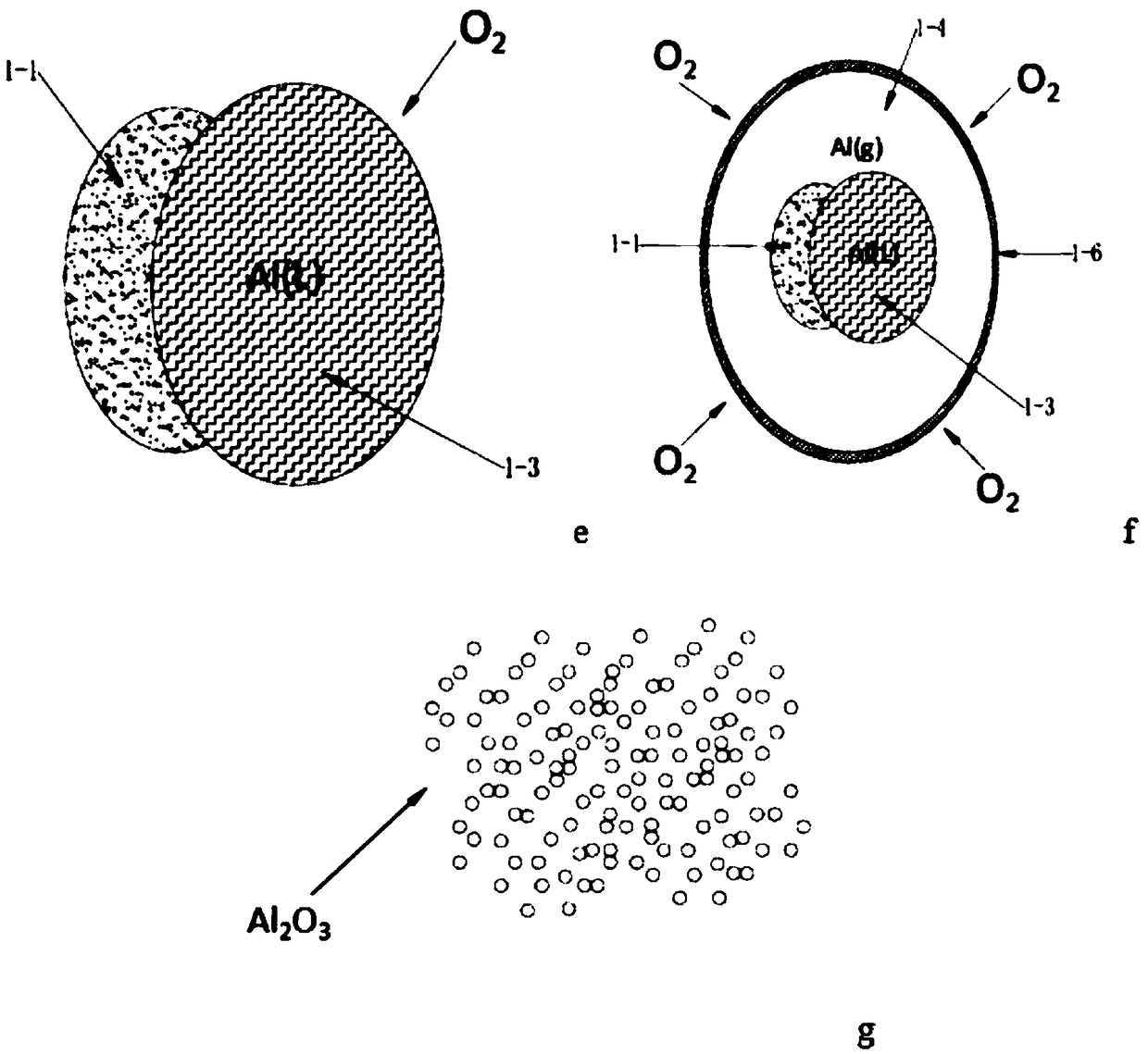

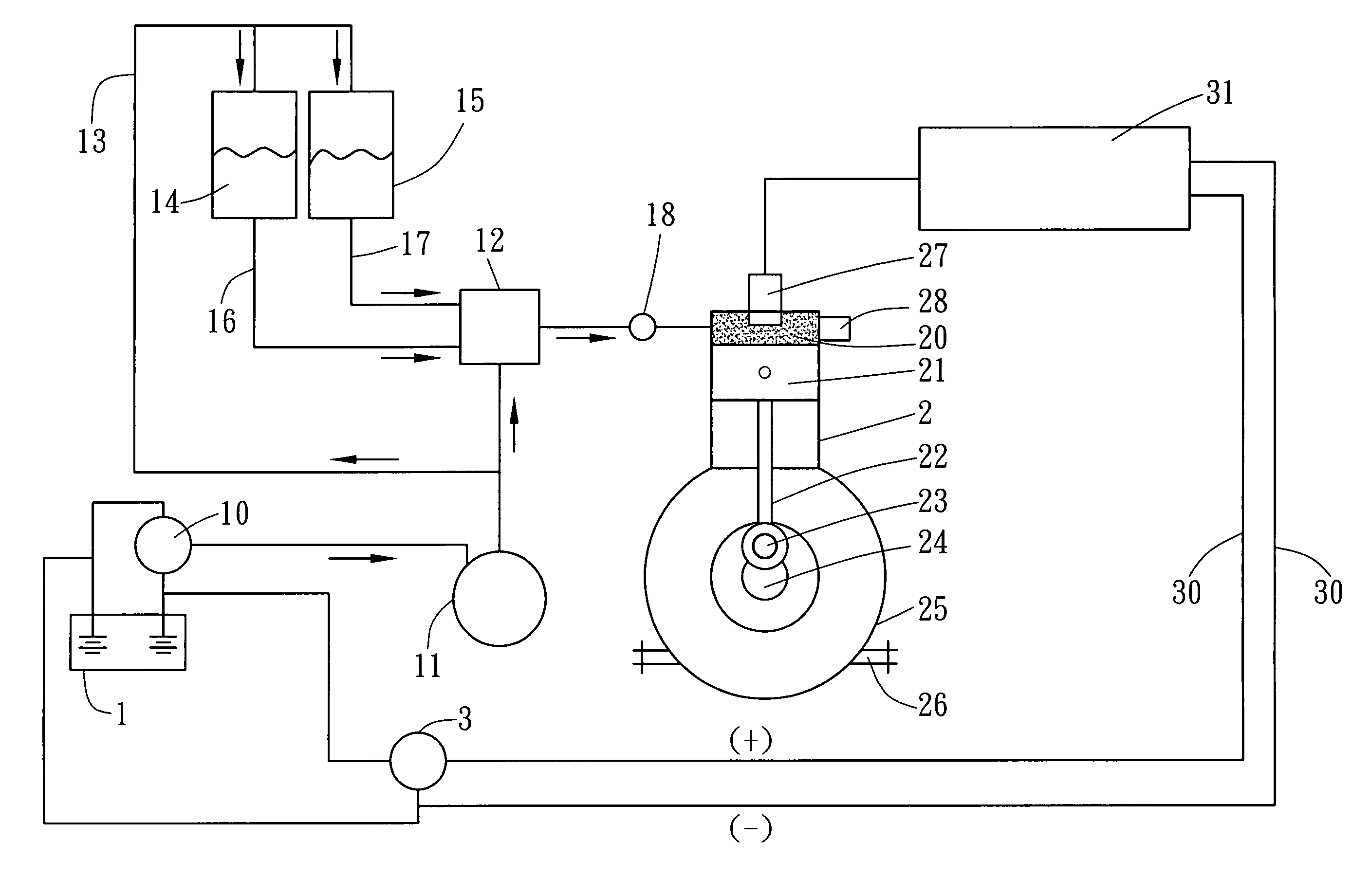

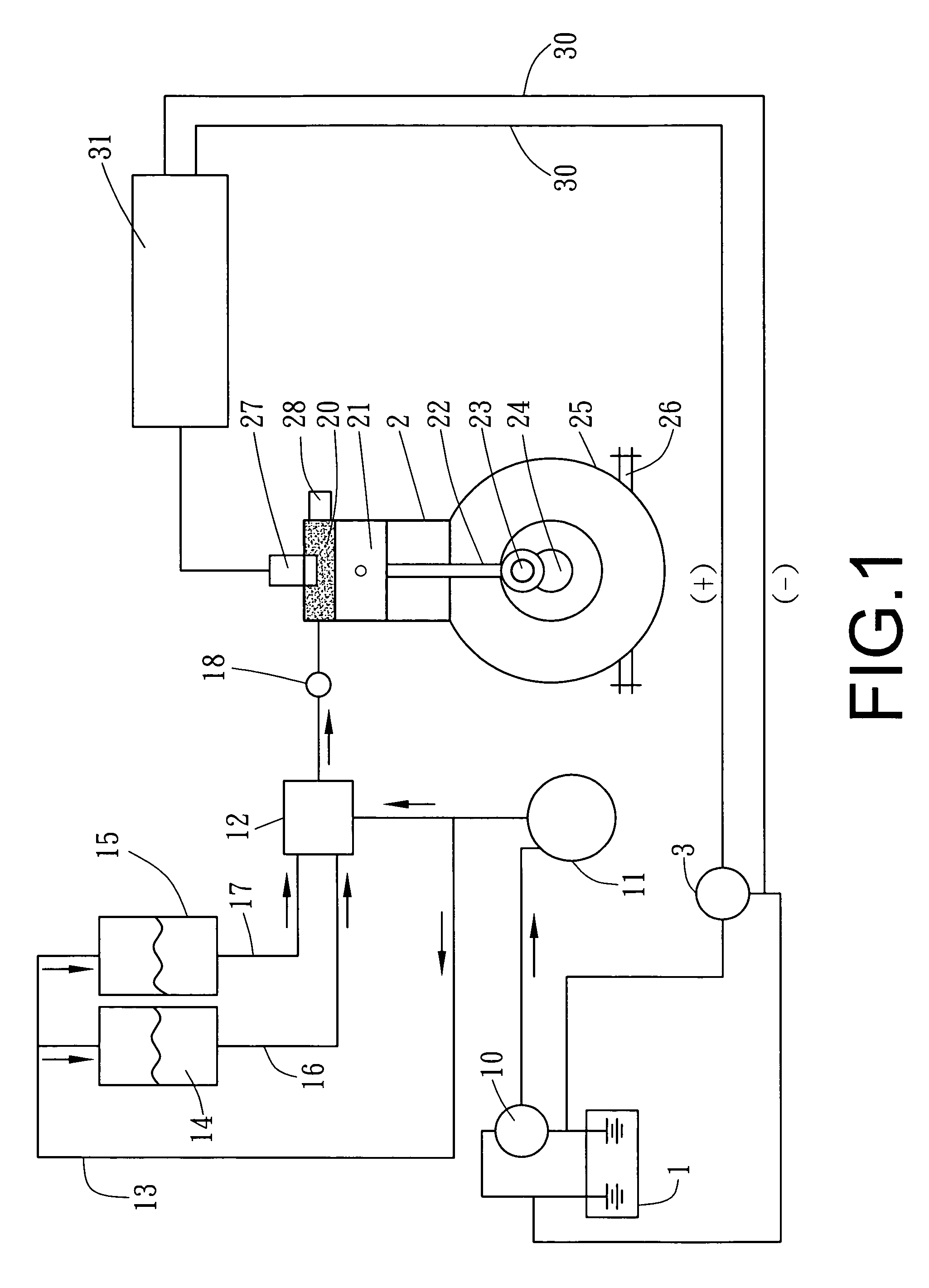

Nano-iron powder fuel power generation method and device

InactiveCN107355300AHigh activityHigh heat of reactionInternal combustion piston enginesExhaust apparatusThermal energyEnvironmental resistance

The invention discloses a nano-iron powder fuel power generation method and device. According to the scheme, nano-iron powder serves as fuel; the nano-iron powder and oxygen are mixed and ignited, and generated thermal energy is converted onto electric energy to realized power generation; hydrogen is introduced into a combustion product Fe3O4 for hydrogen reduction of Fe3O4, and recovery of the combustion product is realized. The nano-iron powder power generation method and device are high in thermal efficiency, friendly to environment, free of pollution, reusable, energy-saving, safe, reliable, low in cost and capable of replacing existing no-renewable energy resources and has great development prospects.

Owner:HEBEI HANGUANG HEAVY IND

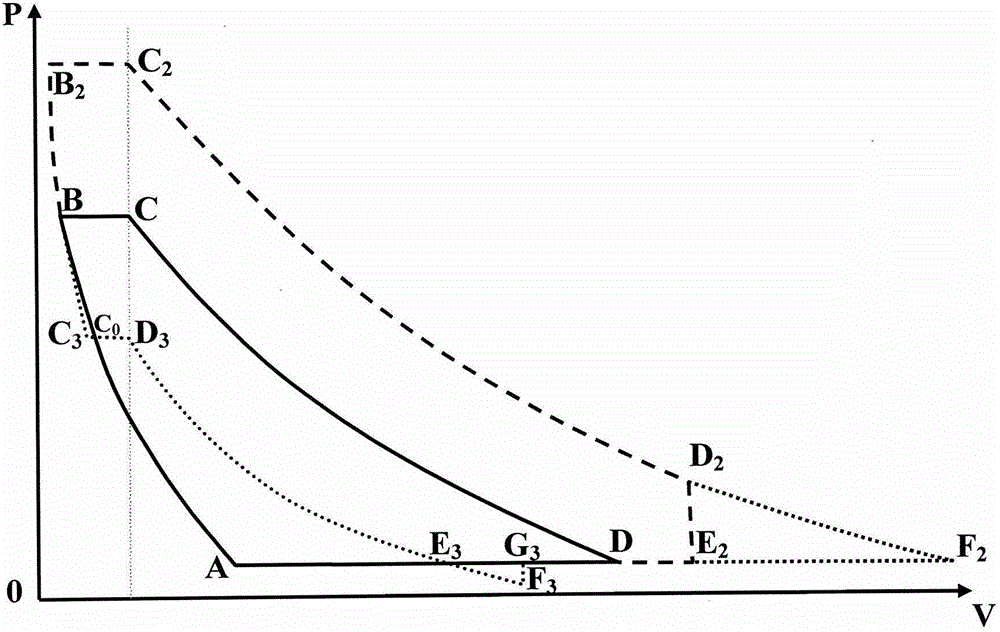

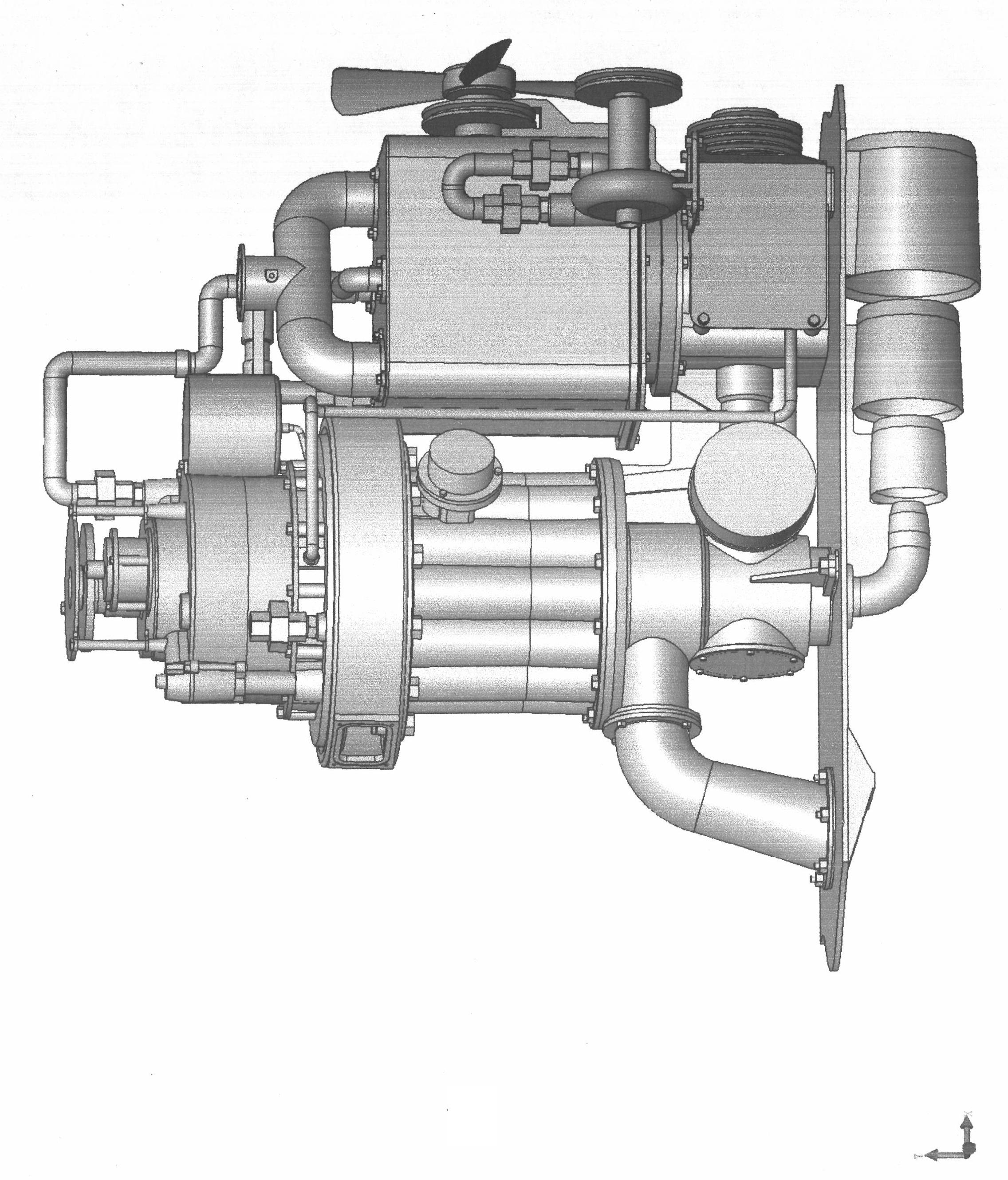

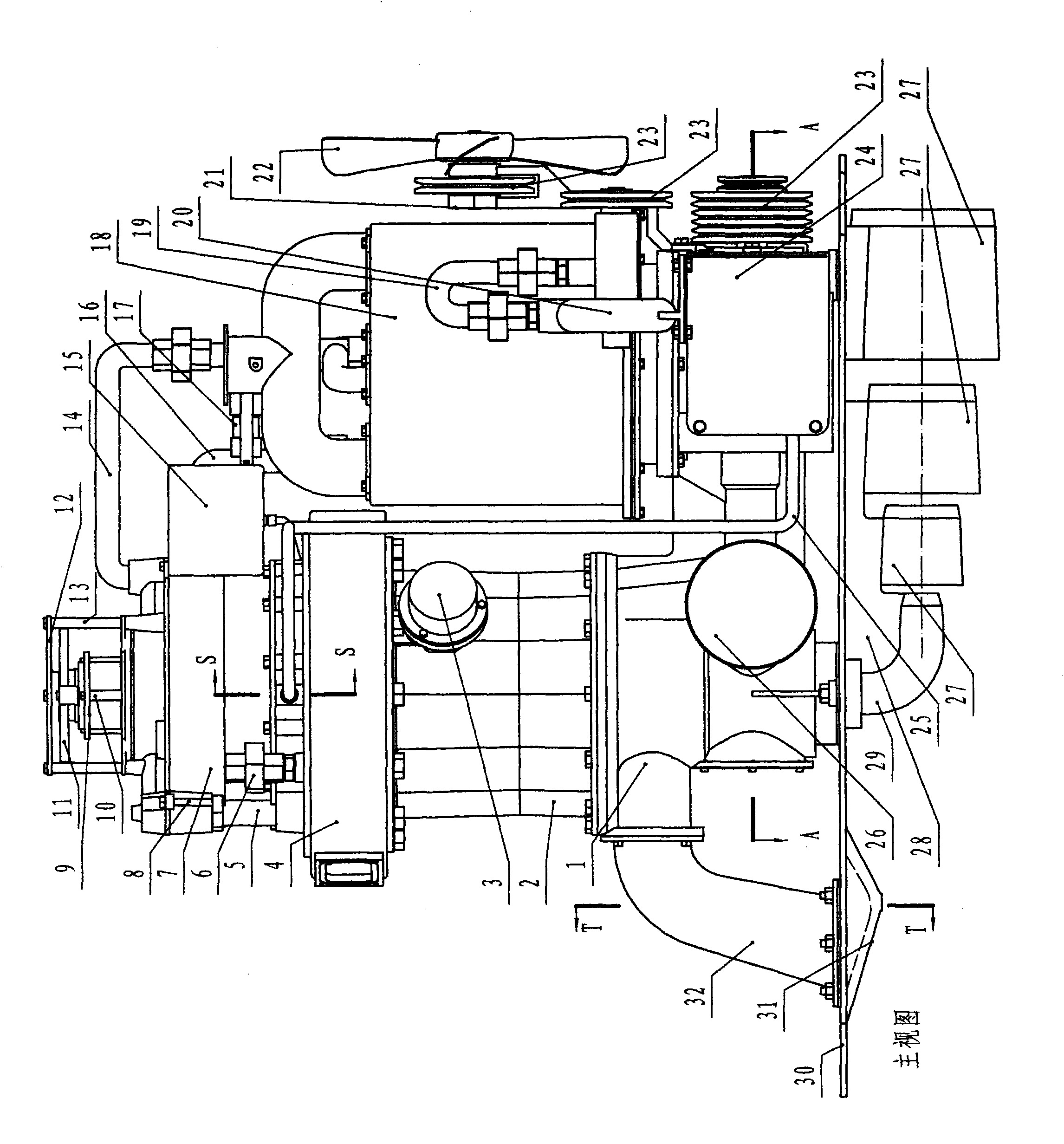

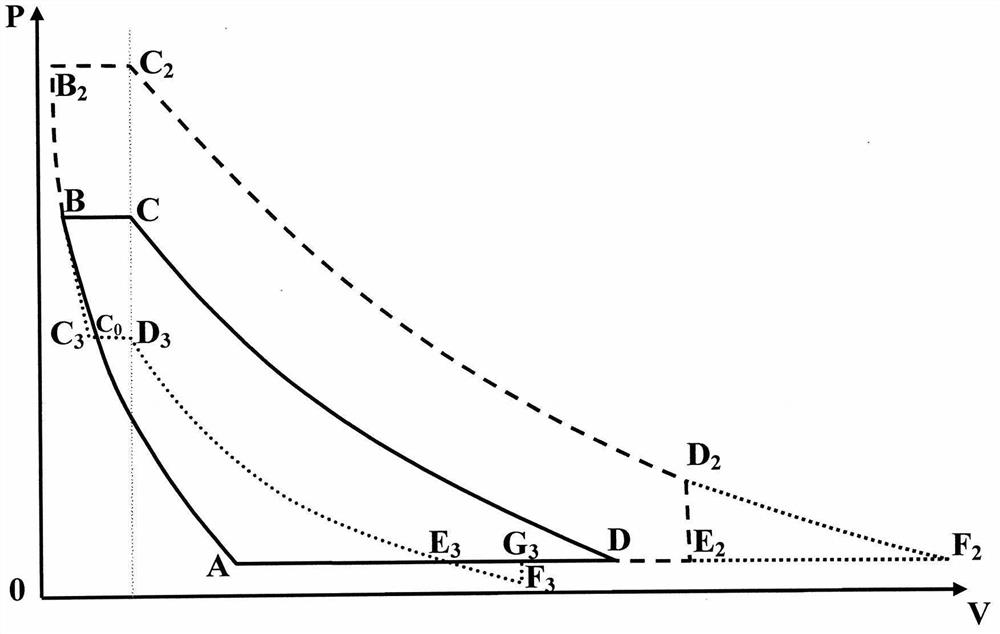

Fuel gas-steam combined cycle equal-pressure variable capacitance slide piece rotor engine

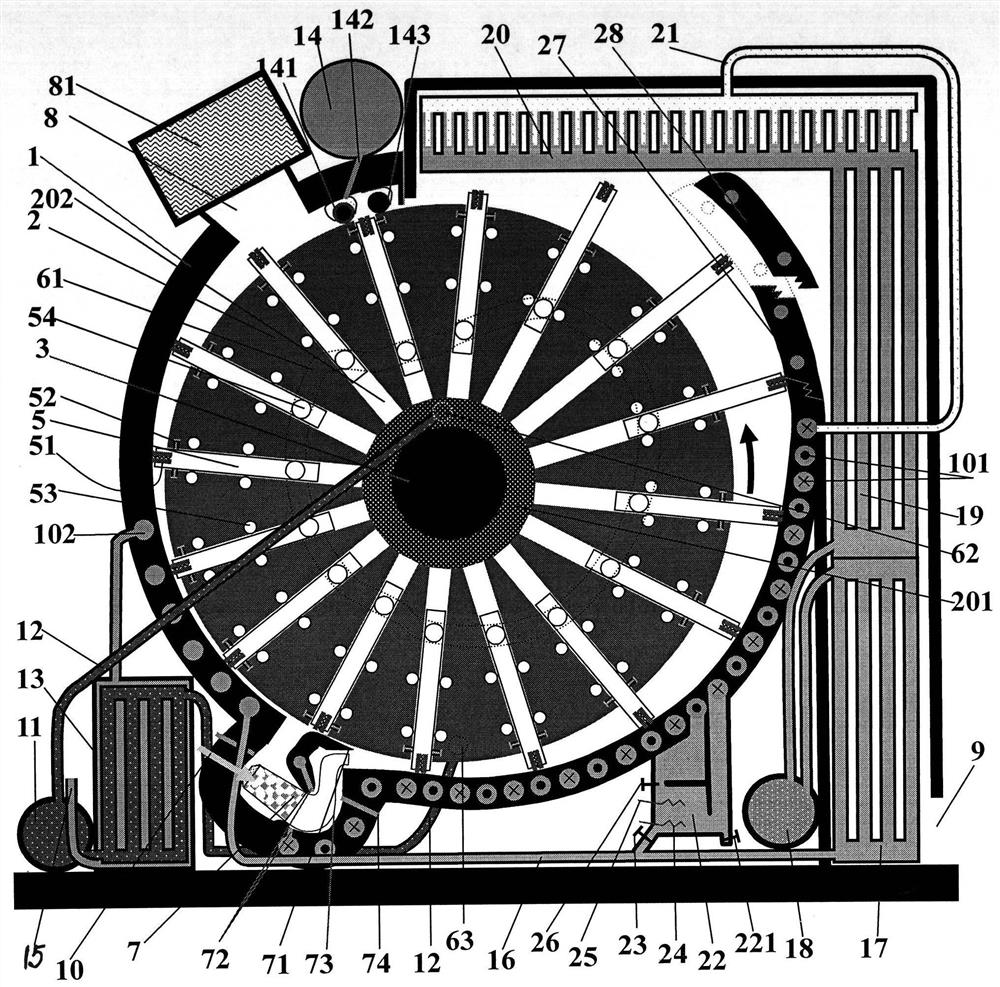

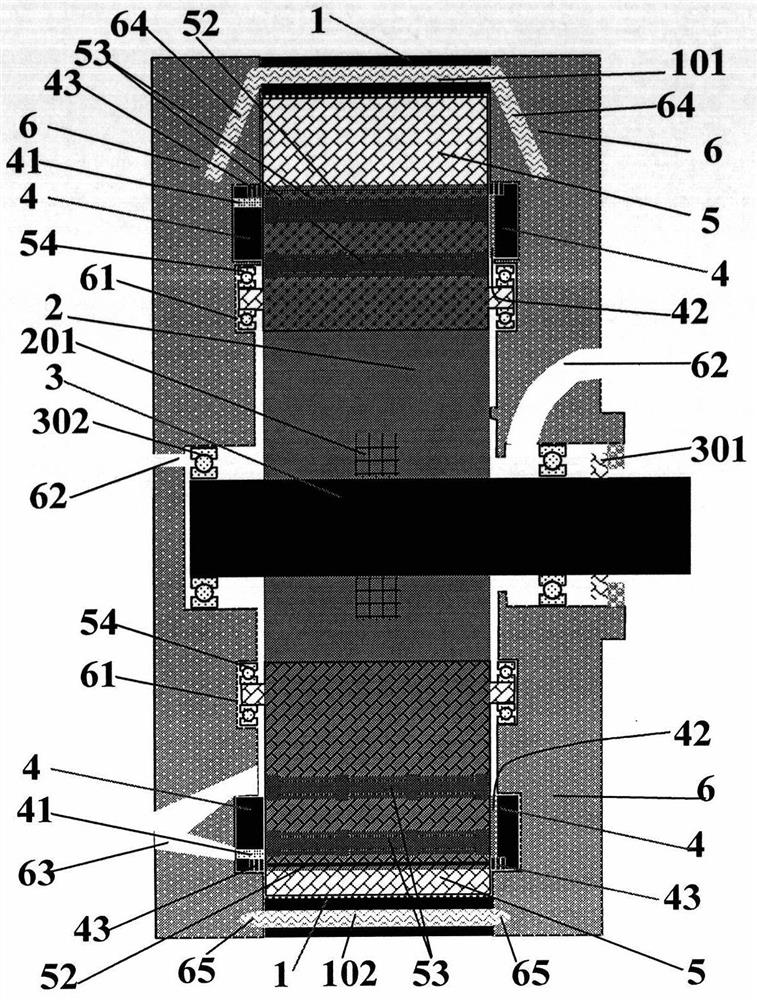

ActiveCN105952526AImprove mechanical efficiencyImprove efficiencyInternal combustion piston enginesGas turbine plantsCapacitanceCombustion chamber

The invention discloses a fuel gas-steam combined cycle equal-pressure variable capacitance slide piece rotor engine, and the engine is similar to an ideal variable high-efficiency combustion gas turbine. A stator shaped like an involute curved surface, a cylindrical rotor, a rotor shaft, a rotor cover, a slide piece assembly, a side cover and a combustor form a basic acting system. The stator, the rotor, the side cover and a slide piece enable the interior to be divided into an air gradual compression chamber (like multistage compression) and a gradual expansion chamber (multistage expansion) which is large in size and acts through fuel gas after combustion. During operation, the rotor rotates to inhale air from an air inlet, carries out gradual compression while the slide piece moves, and enables air to enter the combustor from a compressed air outlet and to be mixed with fuel gas. The gas absorbs heat to expand in an equal pressure manner. Because the compression area of an expansion chamber slide piece is larger than the compression area of a compression chamber slide piece by several times and the pressure intensities are equal, the thrust at the expansion chamber side is greater than the resistance of the compression chamber by several times, an external acting force moment is formed, and an equal-pressure expansion work is done. The expanded gas is divided by the slide piece in the expansion room, and the size of the expanded gas becomes large in operation, and then an adiabatic expansion work is done.

Owner:钱百成

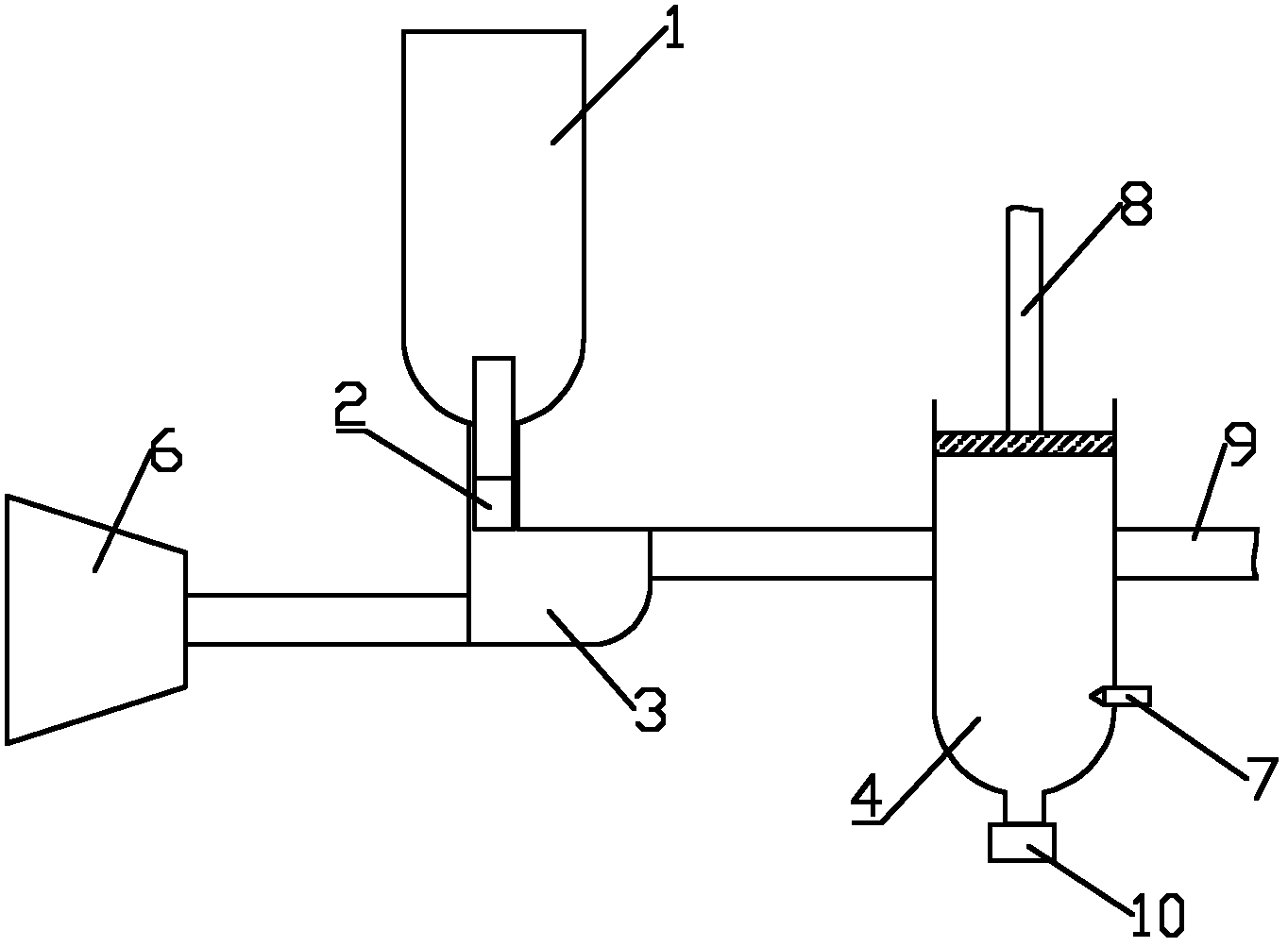

Internal combustion water spray propeller for ship

InactiveCN102009738ASave on fuel costsSimple structureInternal combustion piston enginesPower plants being motor-drivenCombustion chamberPropeller

The invention relates to novel ship power equipment, in particular to an internal combustion water spray propeller for a ship, which drives the ship forward by sucking water outside the ship into a water cylinder body and spraying water in the water cylinder body out of the water spray pipe orifice of the ship by using high-pressure fuel gas produced by the combustion of a fuel inside a combustion chamber of the water cylinder body. The propeller does not need to be driven by an internal combustion engine and does not need a screw propeller or a driving water pump, so that the ship power equipment has a simple structure, lower manufacturing cost and higher reliability; and plant powder or high-quality pulverized coal can be taken as the fuel instead of fuel oil, so that the fuel cost of the ship is lowered.

Owner:汪伯瑞

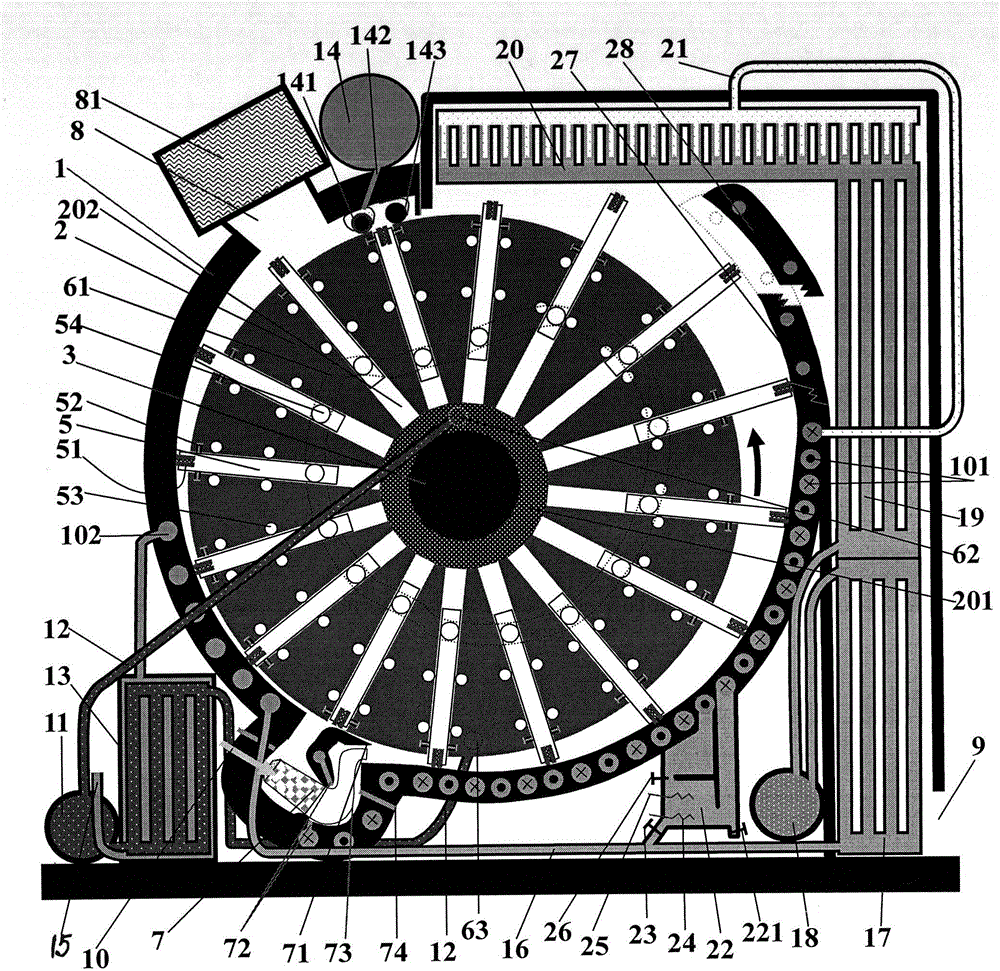

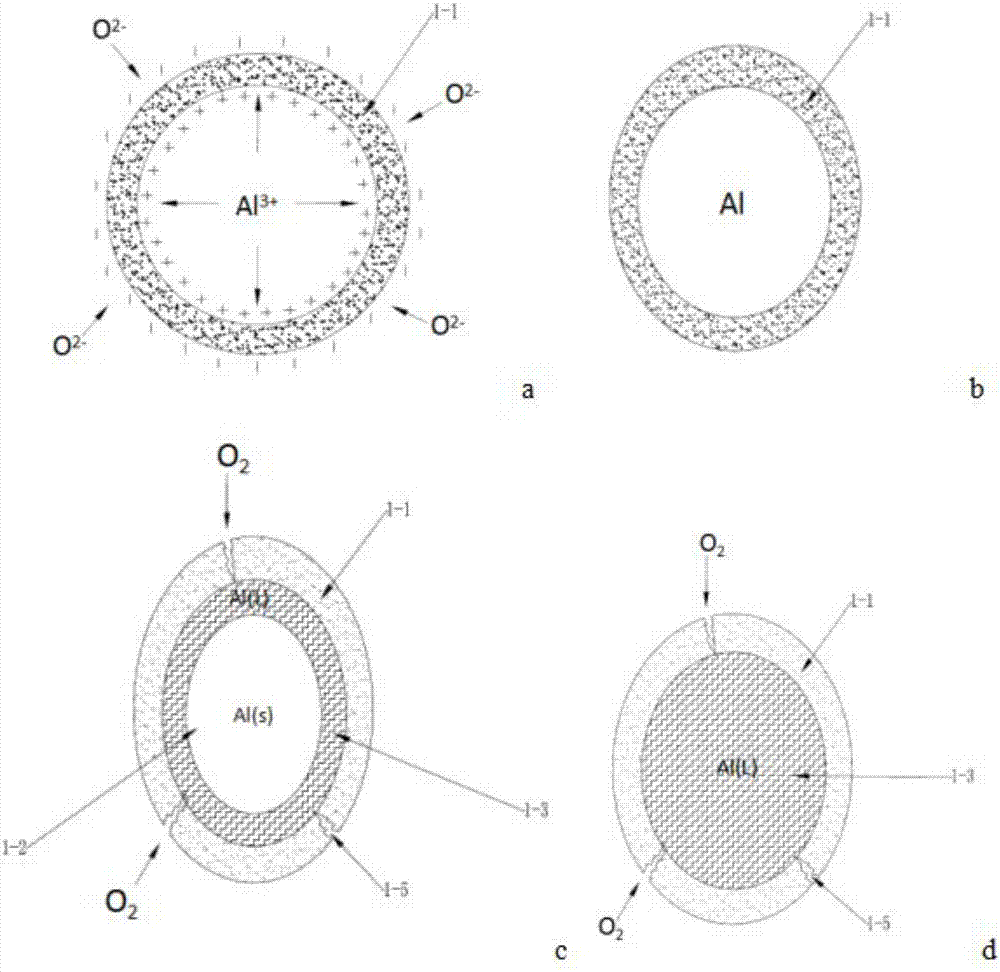

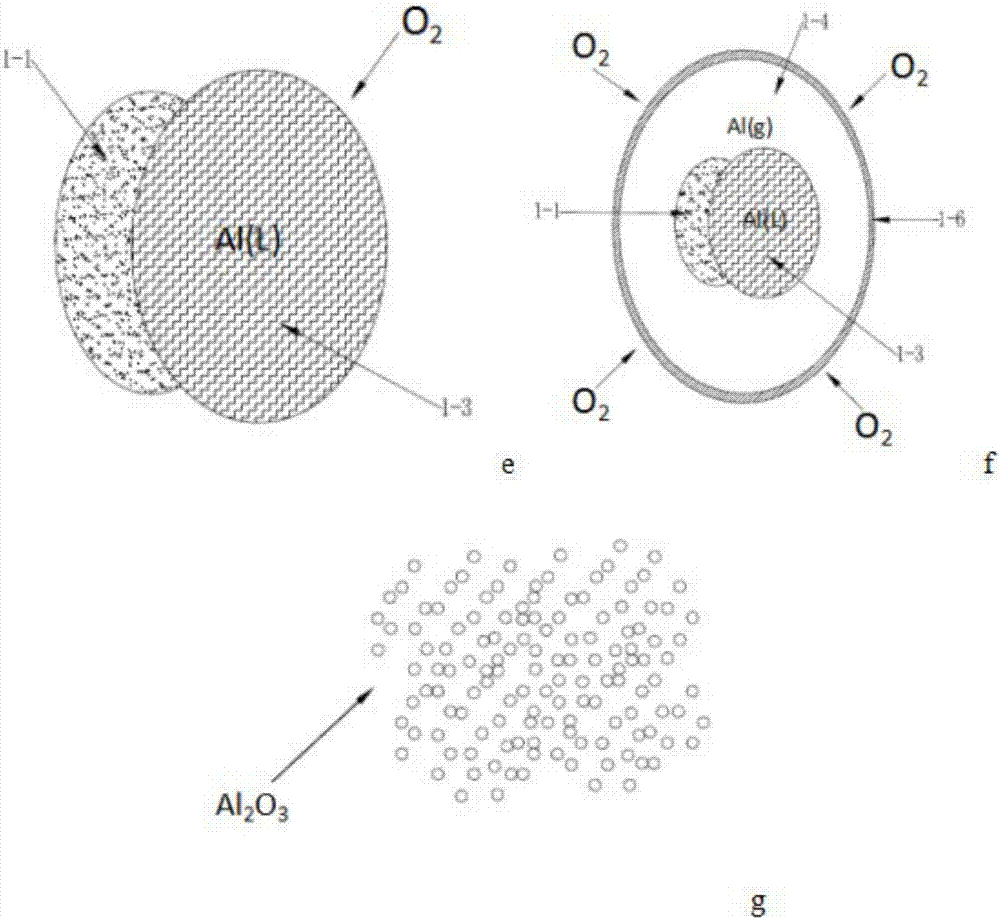

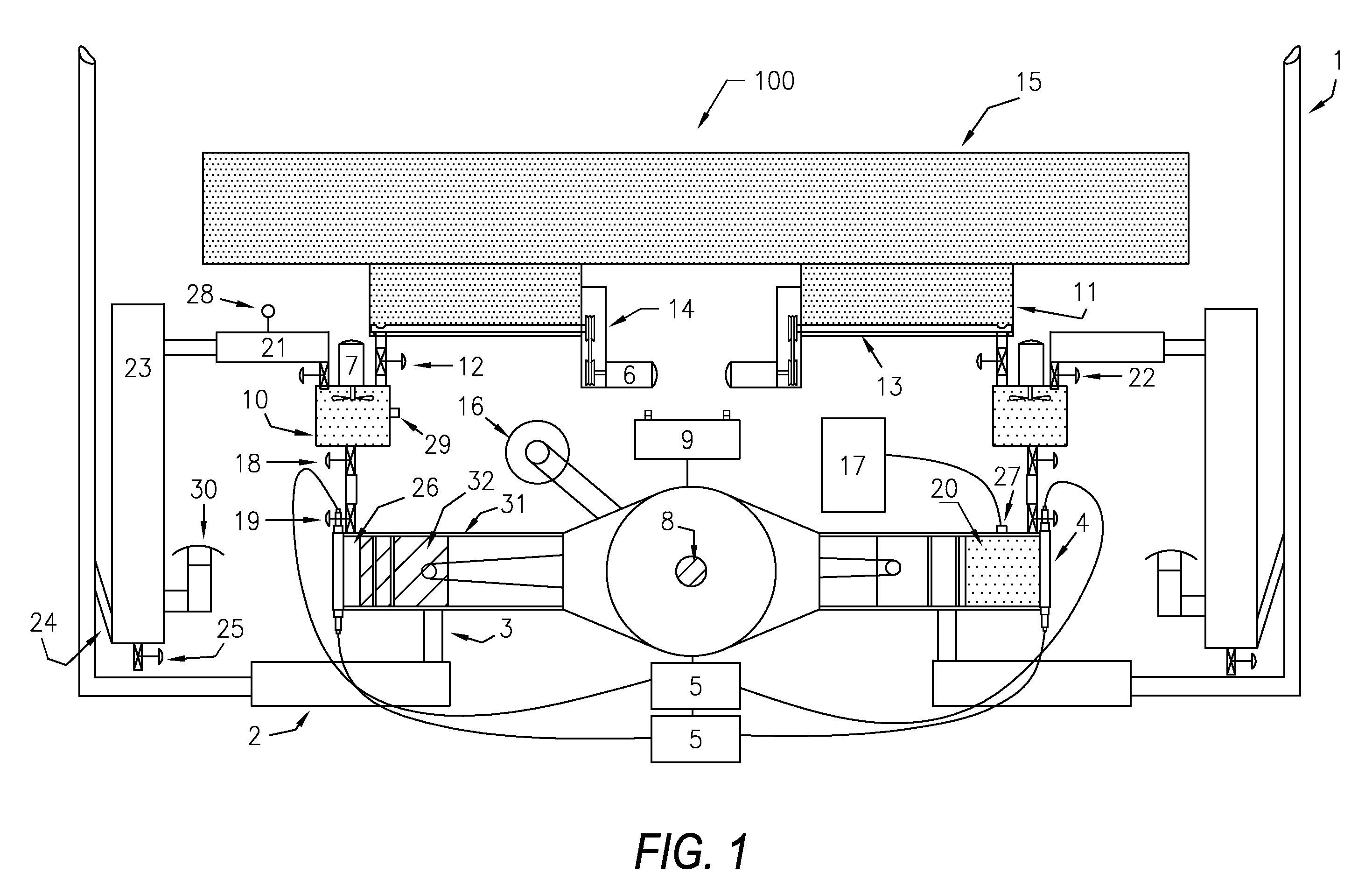

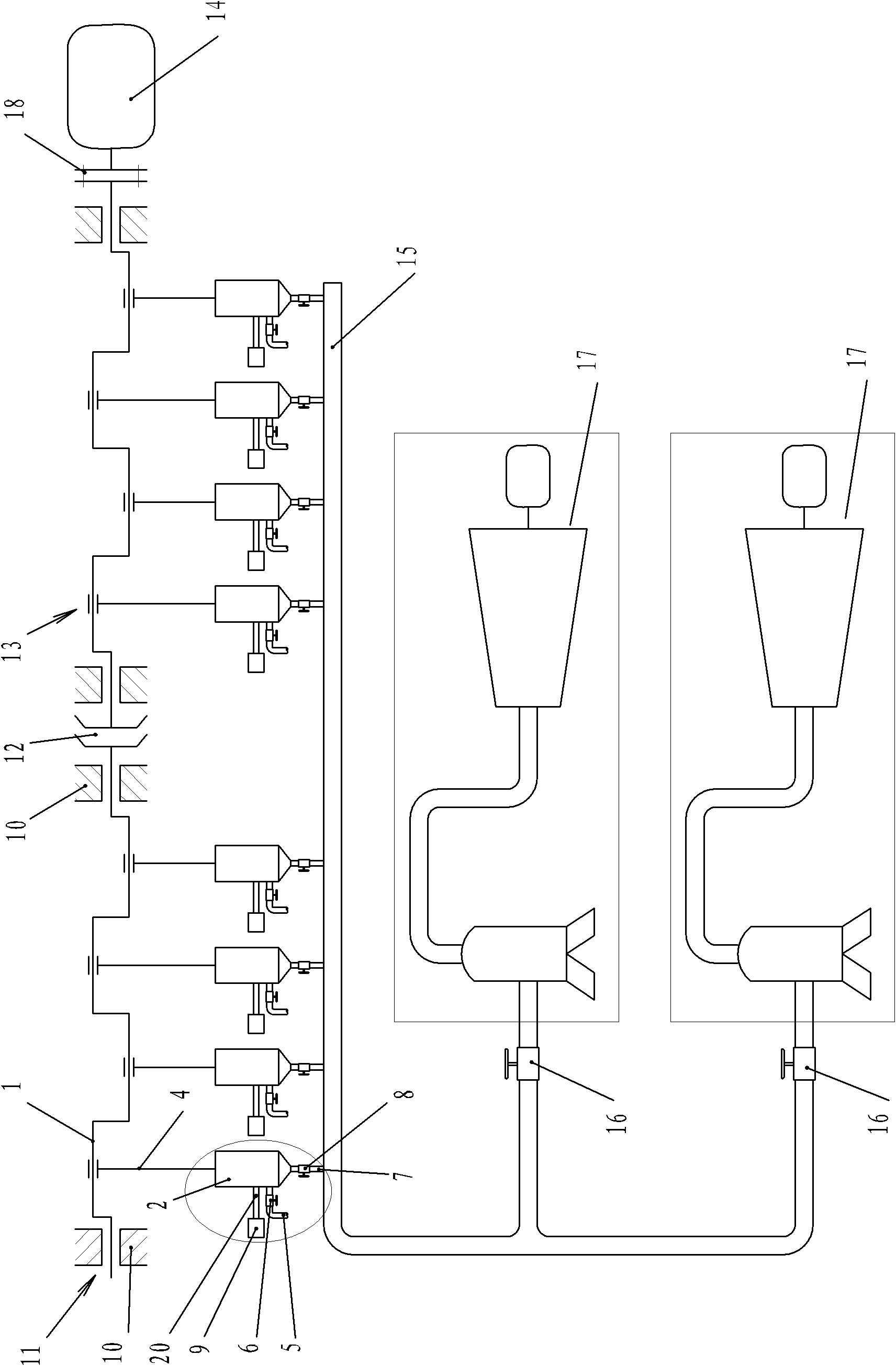

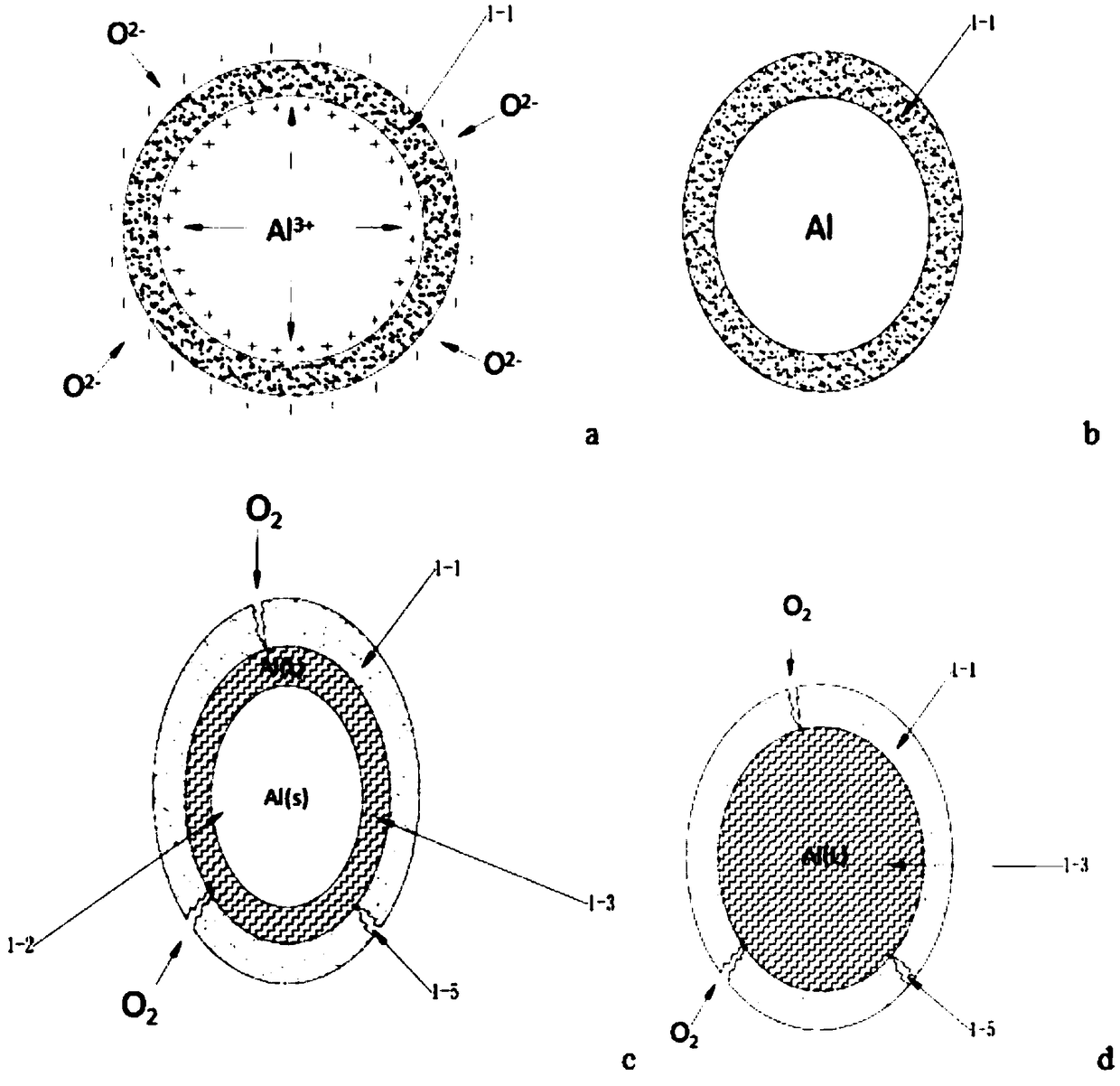

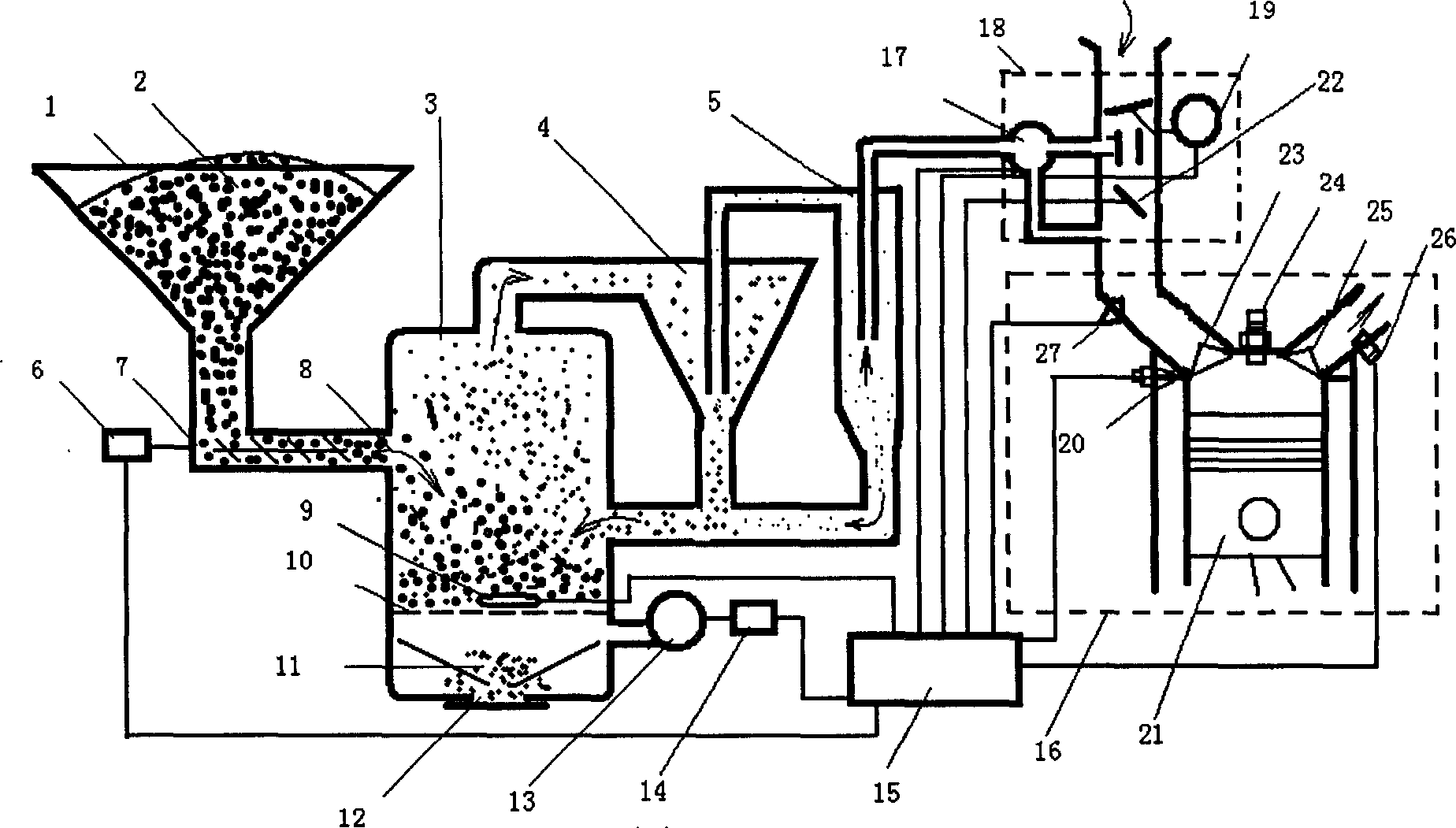

System used for combustion of aluminum powder or magnesium powder and recovery of product generated during combustion

ActiveCN106939829AAvoid emissionsReduce pollution sourcesInternal combustion piston enginesFuel supply apparatusExternal combustion engineFuel tank

The invention provides a system used for combustion of aluminum powder or magnesium powder and recovery of a product generated during combustion. The system comprises a combustion subsystem, a high-pressure fuel gas automatic compensation and storage subsystem, a cooling subsystem, a product recovery subsystem, an external combustion engine and internal combustion engine combined subsystem and an air compression and compensation storage subsystem. The combustion subsystem comprises a compressed air tank, a fuel tank, a combustion tank and a controller. The compressed air tank and the fuel tank are connected to the combustion tank. A fuel gas storage tank of the high-pressure fuel gas automatic compensation and storage subsystem is connected to the fuel tank. A cooling loop of the cooling subsystem is arranged outside the combustion tank and the fuel gas storage tank. A product collection device of the product recovery subsystem is connected to the combustion tank and the fuel gas storage tank. An internal combustion engine of the plasticization is connected to the fuel gas storage tank. The two ends of an air compressor of the air compression and compensation storage subsystem are connected to the internal combustion engine and the compressed air storage tank correspondingly. According to the system, metal powder fuel is adopted, high-pressure gas can be generated in an external combustion engine to drive a machine to act, and energy saving and environmental friendliness are achieved.

Owner:熊朔

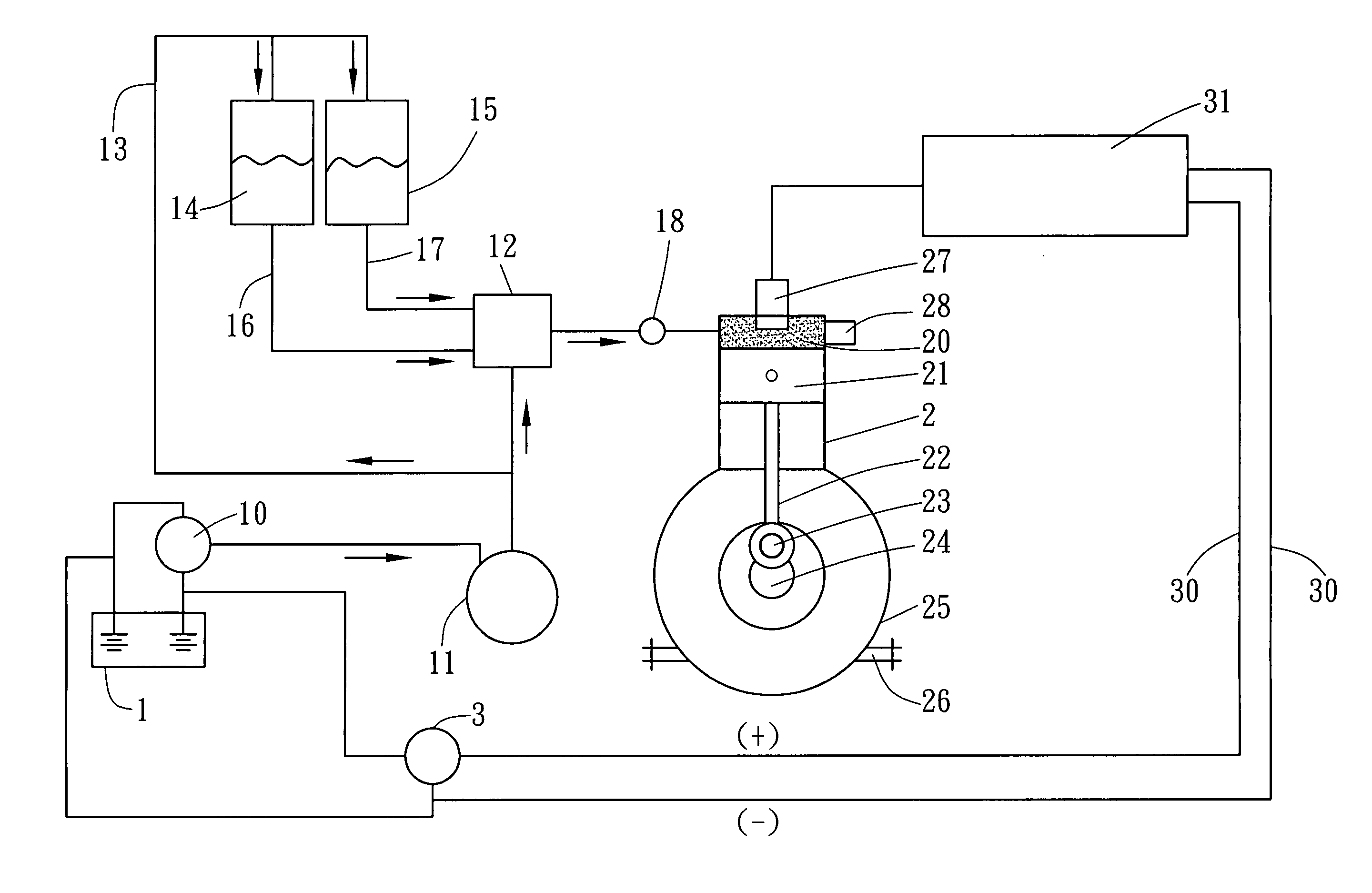

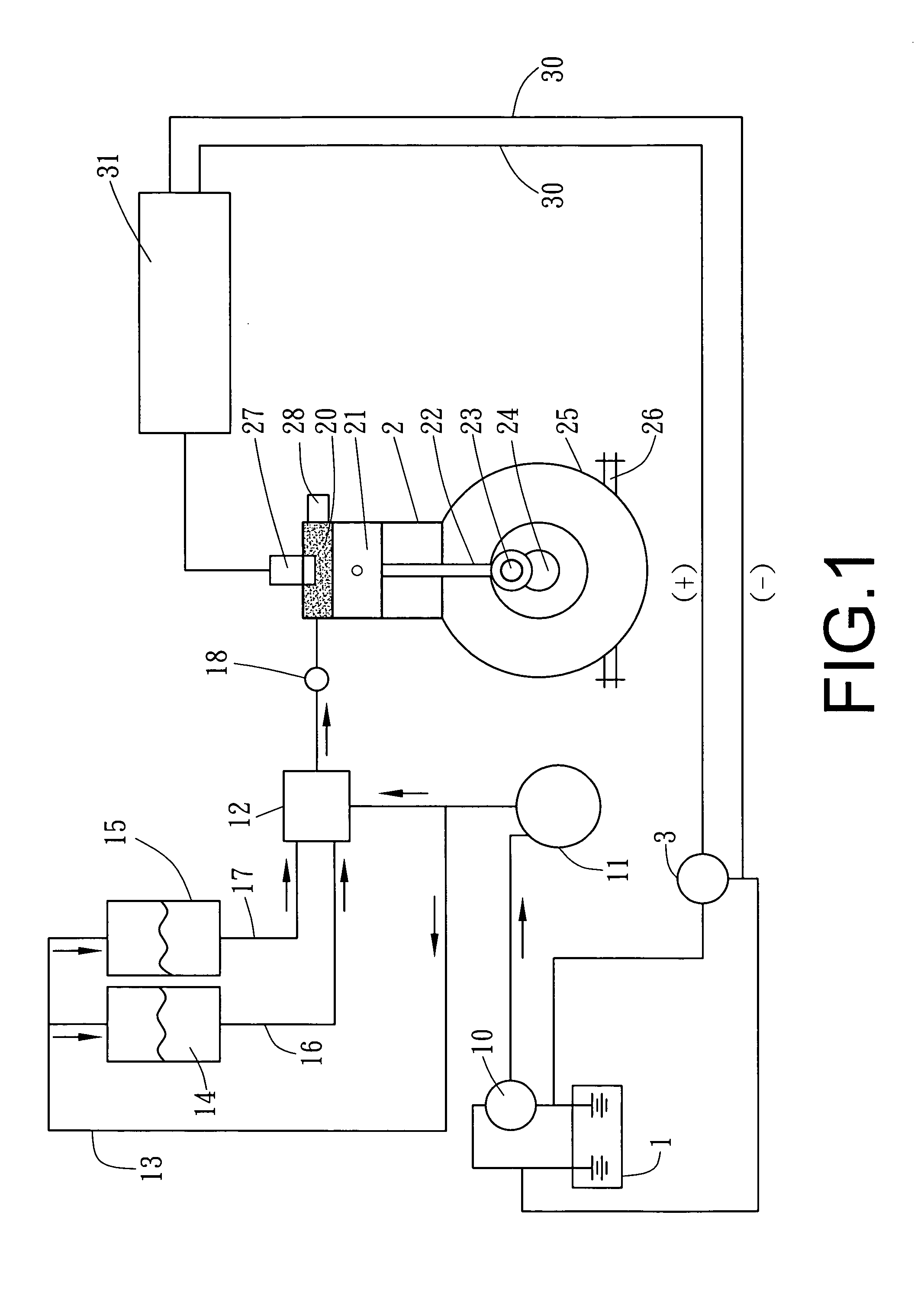

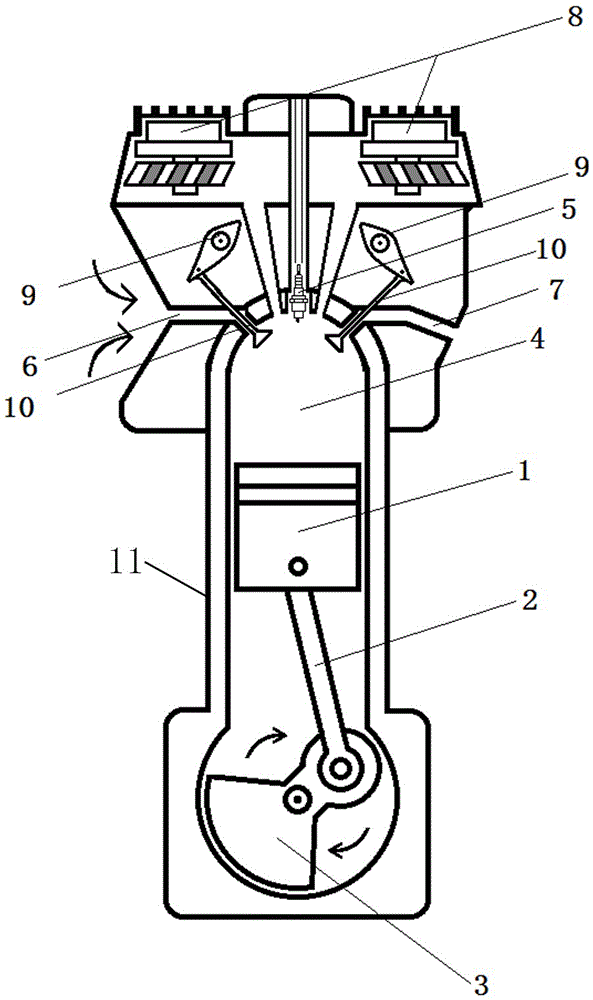

Powder fuel engine

InactiveUS20070266963A1Internal combustion piston enginesGaseous engine fuelsCombustion chamberAir compressor

A powder fuel engine includes a battery, a cylinder and a generator. The battery is connected with an air compressor linked with an air tank, and the generator. The air tank is connected with a mixer and two powder tanks respectively via a pressurization tube. The powder tanks are to store different powders and respectively connected with a powder tube connected with the mixer. A powder jetting device connected to the mixer is connected with the cylinder that is provided with a powder combustion chamber, a piston, a spark plug and an outlet. The piston is connected with a connecting rod that is connected with a shaft. The generator is connected with an ignition device that is connected with the spark plug.

Owner:LIN YI HSIUNG

Power device

InactiveCN102493866AReduce use costLimited sources of solutionsInternal combustion piston enginesPowdered engine fuelsCombustion chamberDust explosion

The invention provides a power device, which comprises a combustible dust container, a mixing chamber and a combustion chamber, wherein combustible dust is stored in the combustible dust container; the first inlet of the mixing chamber is communicated with the outlet of the combustible dust container; air enters the mixing chamber through the second inlet of the mixing chamber; the inlet of the combustion chamber is connected with the outlet of the mixing chamber; and the combustion chamber comprises a driving output part for driving external mechanical equipment. The power device supplies power to the external mechanical equipment by using energy generated during combustion of the combustible dust, so that the problems of finite fuel sources, high cost and severe pollution are solved, and the using cost of the external mechanism equipment is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

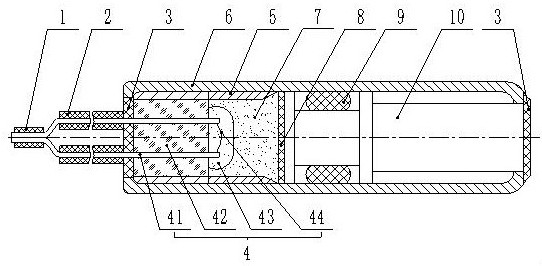

Initiating explosive actuator adopting low detonation velocity charging to reduce incidental impact and pollution

ActiveCN111734526AReduce collateral impactReduce leakageInternal combustion piston enginesPowdered engine fuelsPotassium nitrateExplosive Agents

The invention discloses an initiating explosive actuator adopting low detonation velocity charging to reduce incidental impact and pollution. The initiating explosive actuator comprises a short circuit sleeve, an insulating sleeve, a sealant, an electric igniter, a reinforcing ring, a tube shell, a driving explosive, a gasket, a sealing ring and a piston, wherein the electric igniter is composed of an electrode plug, igniting powder, an igniter wire and two conducting wires. The igniting powder is trinitro-resorcinol lead or other weak initiating explosives and ignition powder. The driving explosive is a low-detonation-speed and low-power explosive and can be a hexogen or pentaerythrite tetranitrate-based granular foam explosive, modified black powder, a boron / potassium nitrate ignition explosive, or a pentaerythrite tetranitrate-based PBXN301 mixed explosive and the like. The initiating explosive agent in the traditional initiating explosive actuator is partially or completely replaced by a low-power agent, so that the incidental impact and pollution of the initiating explosive actuator during working can be reduced, the reliability of fuses, ammunition and spacecrafts is improved, and the intrinsic safety of matched products is improved.

Owner:NANJING UNIV OF SCI & TECH

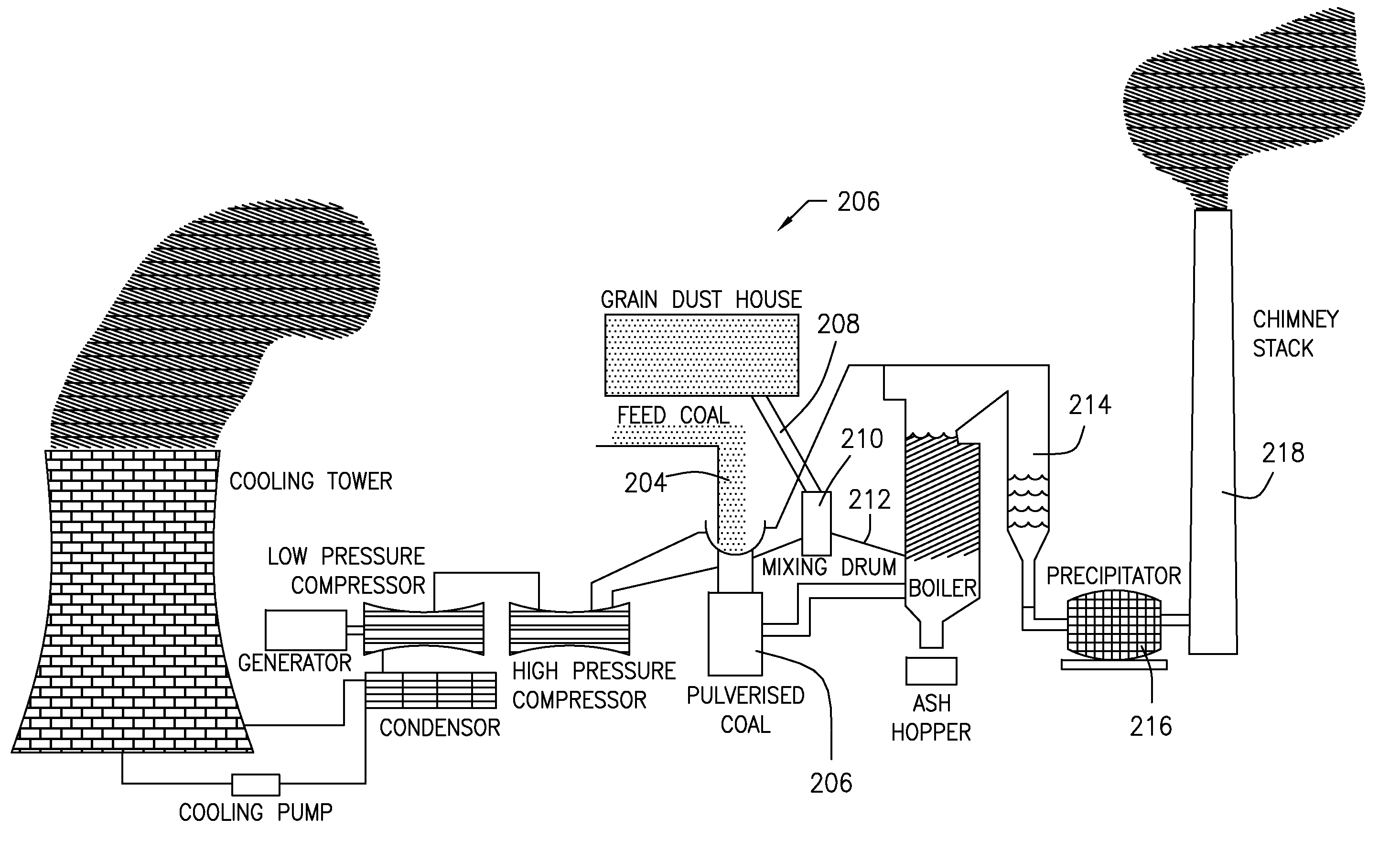

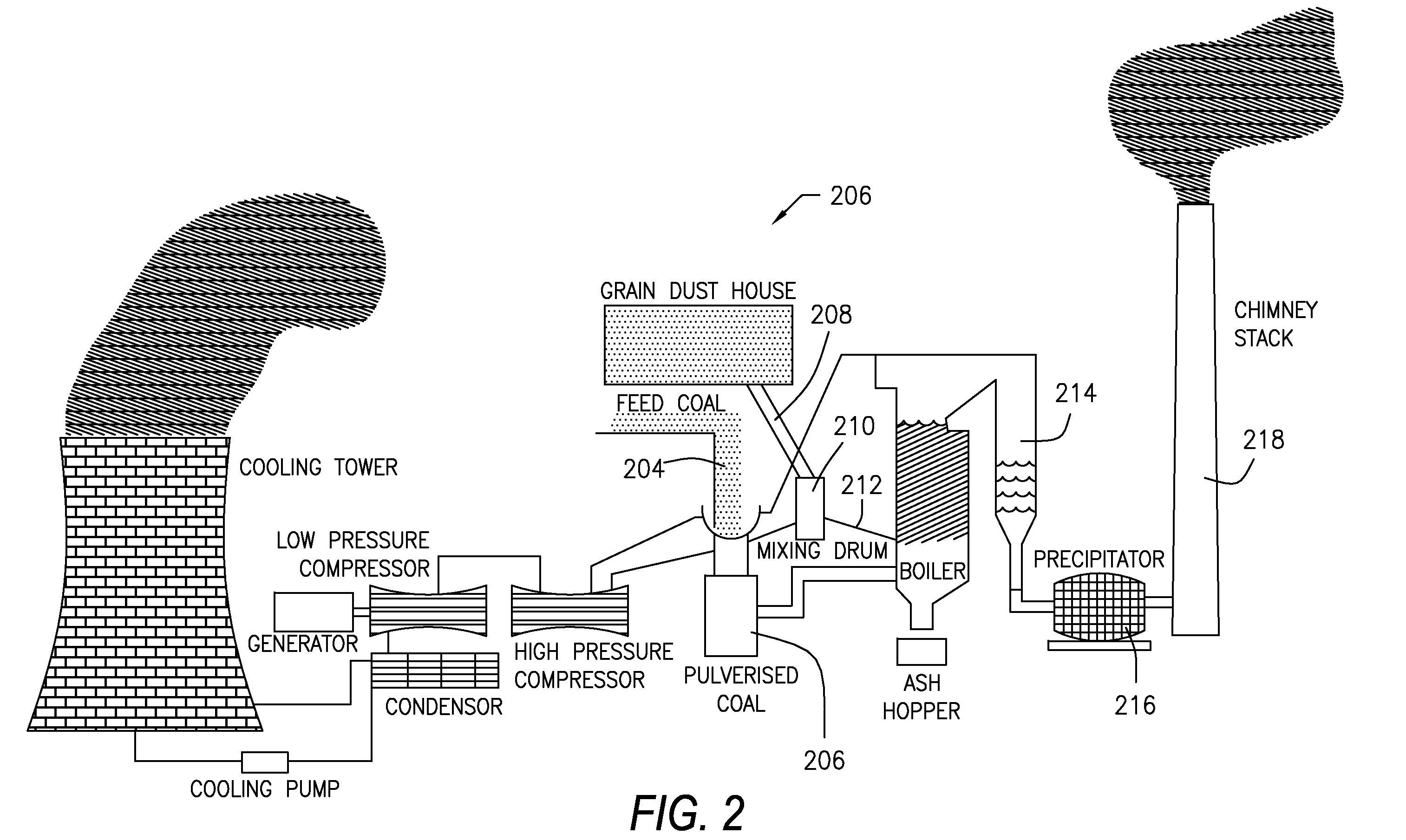

Particulate Deflagration Enhanced Firebox

InactiveUS20110048294A1Internal combustion piston enginesFuel supply apparatusElectricityParticulates

A particulate deflagration enhanced firebox for burning particulate fuel either alone or in combination with other fuels and the associated method. The firebox may be employed in association with a power plant where the heat from the firebox is used to generate electricity. Fine fuel particles are fed to a mixing drum or box by a pre-measured auger system where the fuel is mixed with dried, compressed combustion air in a desire fuel to air ratio. The fuel mixture enters the combustion firebox or boiler either alone or in association with other fuels where it is ignited. The hot combustion gases leave the firebox and are vented through the firebox's normal route which generally includes passing through a precipitator for remove particulates before exiting to atmosphere via a chimney stack.

Owner:DEFLAGRATION ENERGY

Common rail supplementary atomizer for piston engines

InactiveUS20080098987A1Large air volumeRapid and completeNon-fuel substance addition to fuelInternal combustion piston enginesCommon railProduct gas

A common rail supplementary atomizer of this invention, when used on a piston internal combustion engine, equipped with a common rail fuel injection system, improves slurry atomization, following injection, by expansion of gases, previously dissolved in the water phase of the slurry. This gas expansion separates the several fuel particles in each slurry droplet formed first during fuel injection. The thusly separated fuel particles subsequently burn more rapidly and completely, due to this fuel particle separation improving air access to the fuel. Apparatus is described for dissolving atomizing gas into the water phase of the slurry, in a contactor chamber at a pressure greater than the pressure prevailing in the engine cylinder volume, at the time of slurry injection.

Owner:FIREY JOSEPH CARL

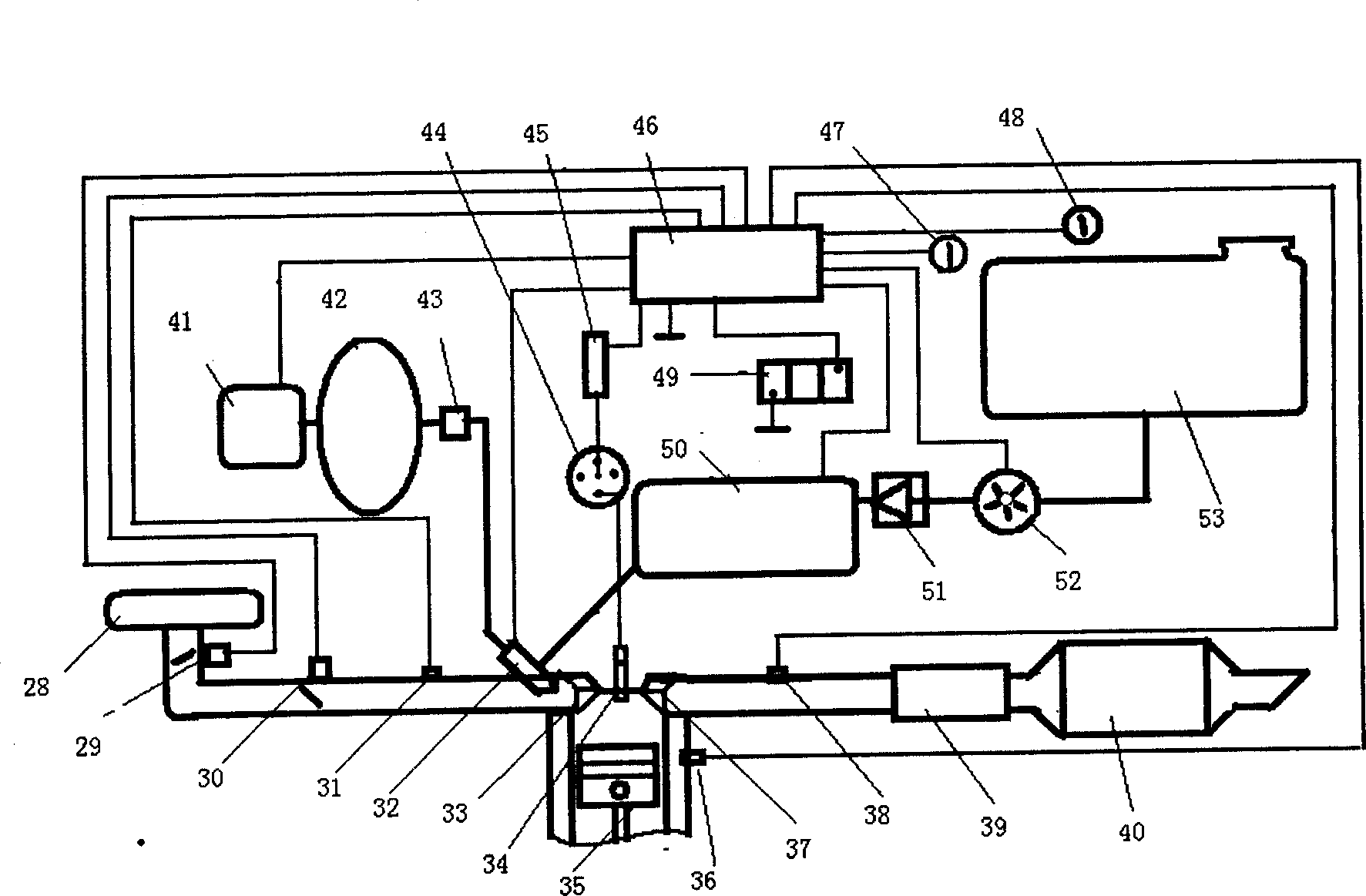

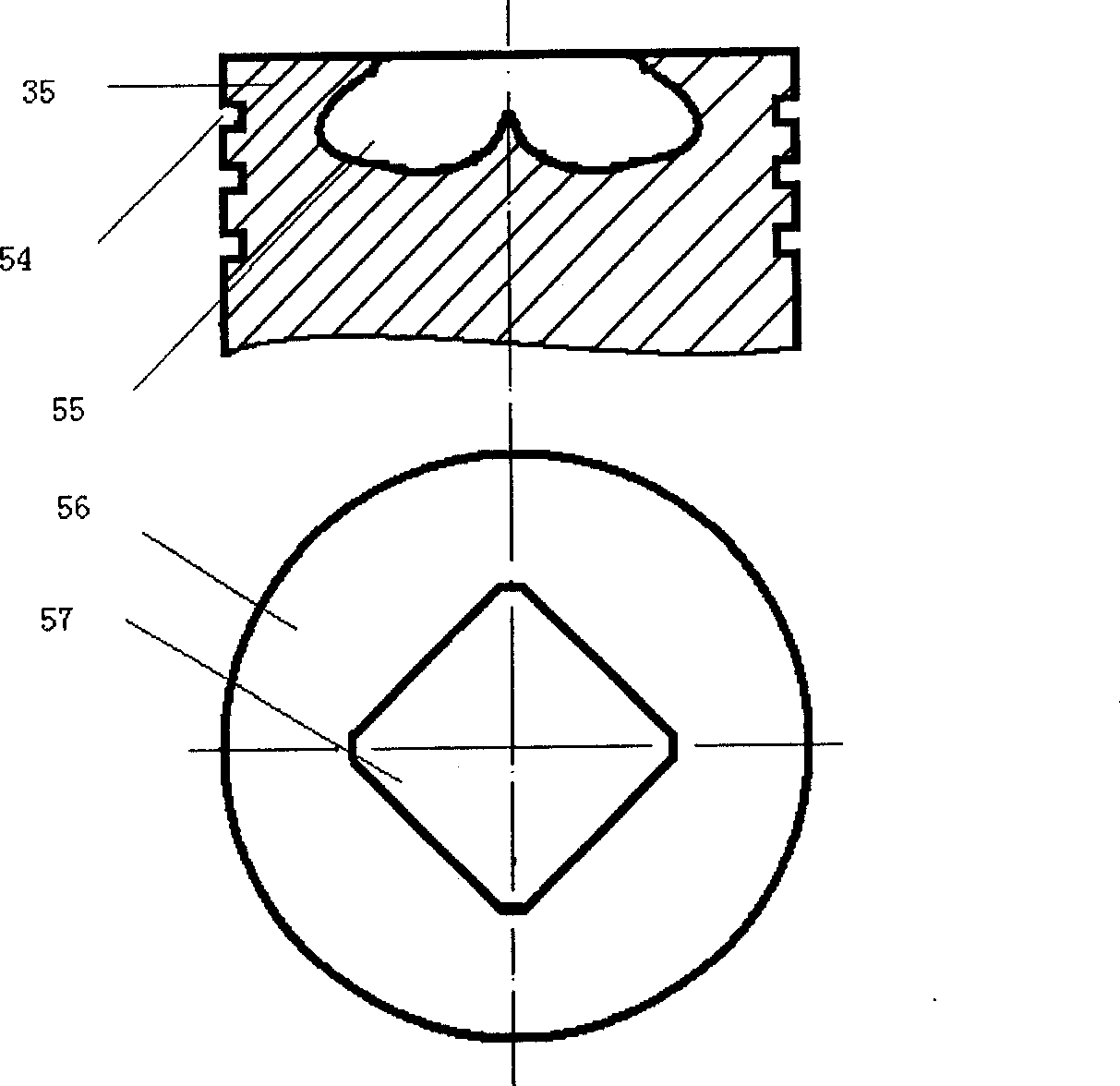

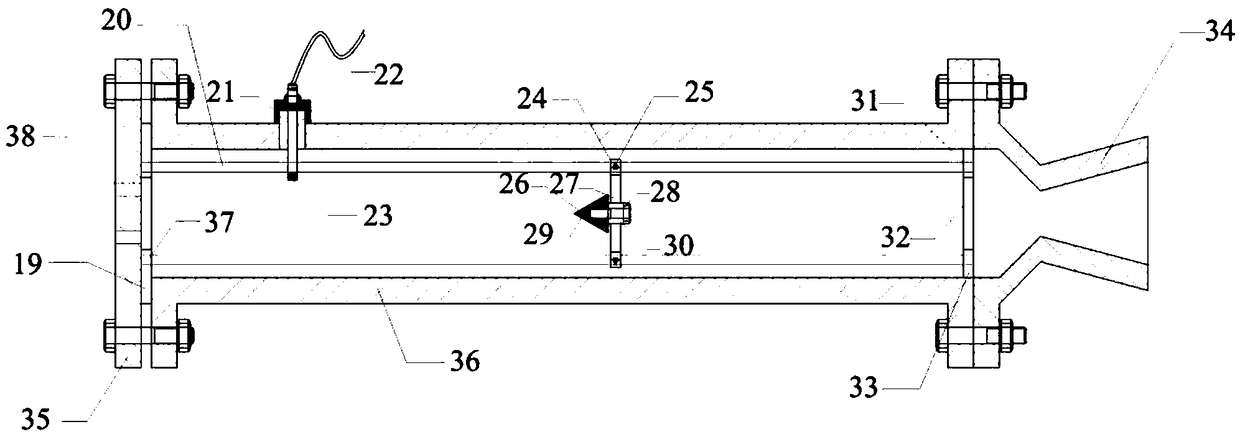

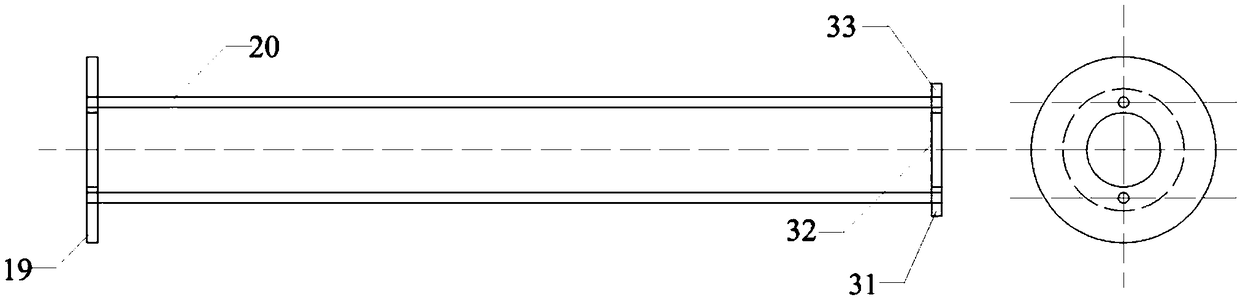

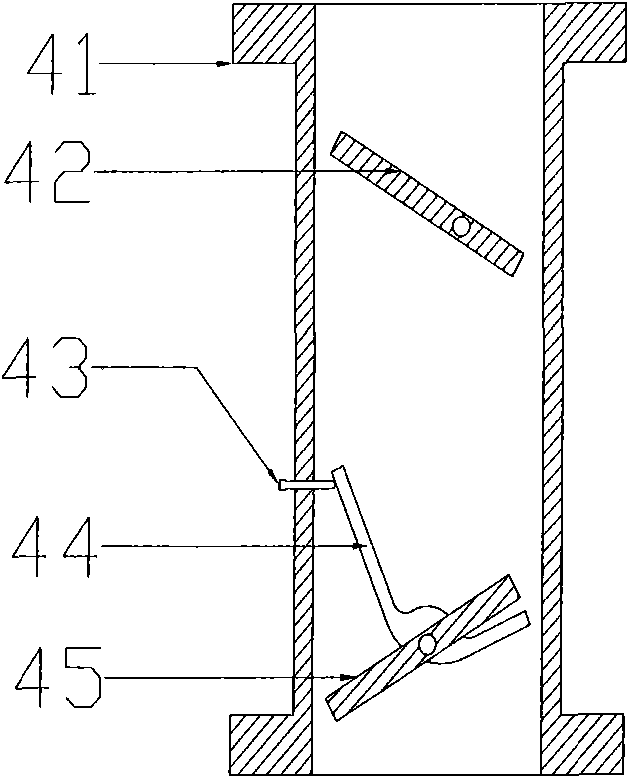

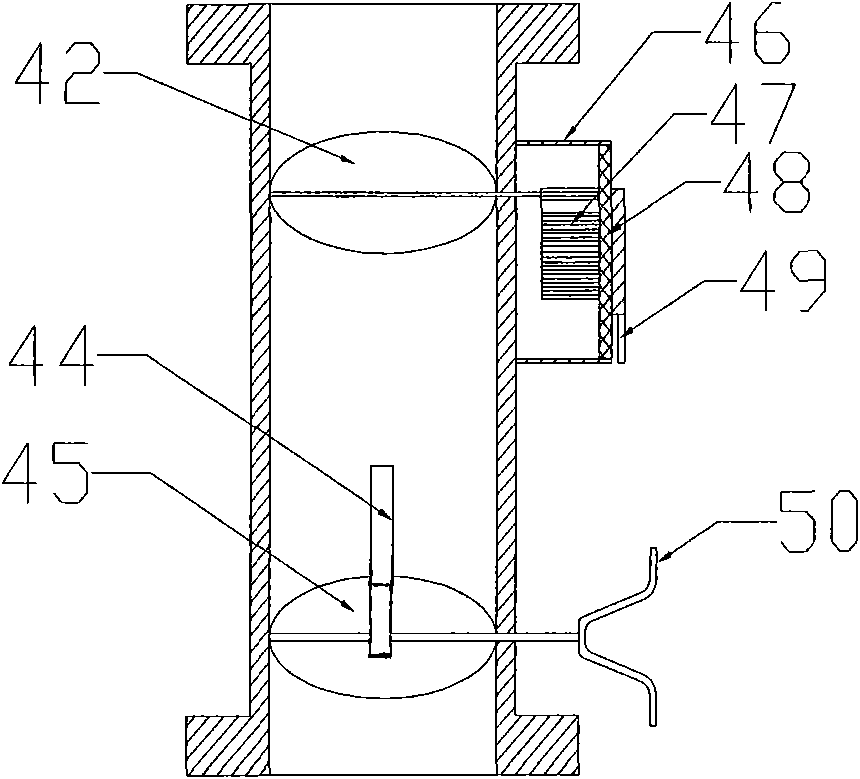

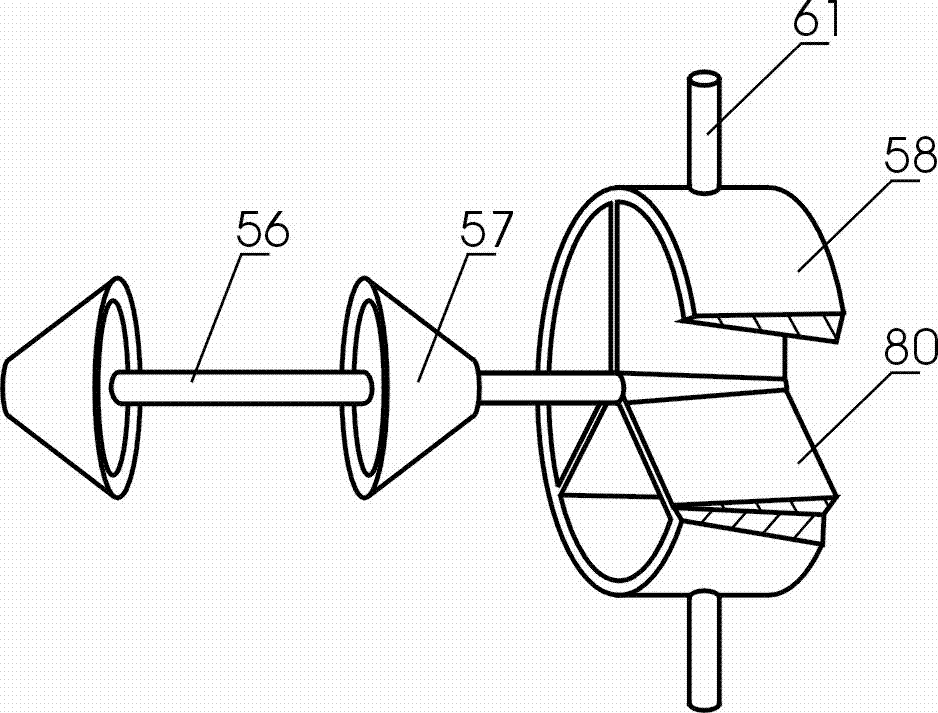

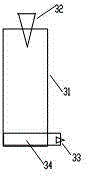

Powder engine with adjustable flame stabilizer position and method for installing flame stabilizer of powder engine

ActiveCN109057953ABurn fullySimple structureInternal combustion piston enginesPowdered engine fuelsCombustion chamberEngineering

The invention provides a powder engine with an adjustable flame stabilizer position and a method for installing a flame stabilizer of the powder engine. The engine comprises a powder fuel supplying device, a powder oxidizing agent supplying device, a combustion chamber 36 and a spraying pipe 34, wherein the powder fuel supply device, the powder oxidant supply device and the combustion chamber 36 are connected with the front end of the combustion chamber 36 through pipelines, the rear end of the combustion chamber 36 is connected with the spraying pipe 34, a flame stabilizer 29 is arranged in the combustion chamber 36, and the axial position of the flame stabilizer 29 in the combustion chamber 36 can be adjusted. The position of the flame stabilizer is adjustable, and the axial position ofthe flame stabilizer can be adjusted according to the requirements of different operating conditions of the engine, so that more sufficient combustion of fuel can be realized, and a detachable fixingdevice of the flame stabilizer is simple in structure, practical and convenient to adjust.

Owner:NANJING UNIV OF SCI & TECH

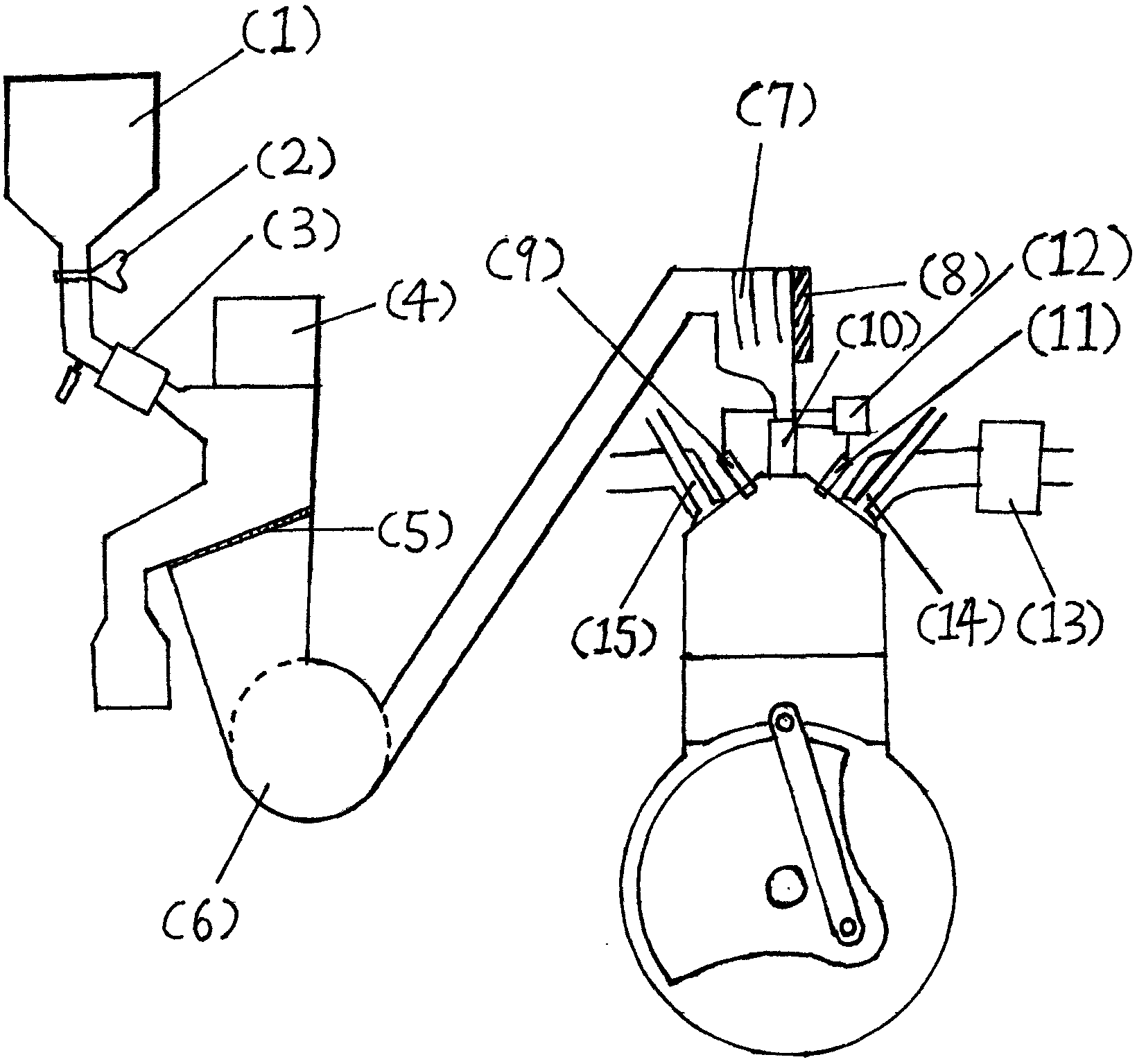

Automobile carbon powder engine

InactiveCN101576004ASave resourcesPowerfulInternal combustion piston enginesPowdered engine fuelsThrottle controlCombustion chamber

The invention relates to an automobile carbon powder engine which comprises a fuel engine main body and a fuel preparation mechanism. The fuel preparation mechanism comprises a carbon powder tank, a fuel supply mechanism, a gas distribution mechanism, a carbon powder and air mixing and stirring mechanism and a throttle control valve, wherein the carbon powder tank is filled with carbon powder and provided with an inlet connected with an external carbon powder box and an outlet connected with the fuel supply mechanism through a feed inlet; carbon powder falling from the carbon powder tank is conveyed by the fuel supply mechanism to the carbon powder and air mixing and stirring mechanism which is connected with the gas distribution mechanism by an intake flue, uniformly mixes the carbon powder and the air and is connected with a combustion chamber of a common fuel engine by an air inlet flue; and the throttle control valve is arranged between the carbon powder and air mixing and stirring mechanism and the air inlet flue and used for controlling the feeding amount of the engine combustion chamber. The invention effectively saves petroleum resources, has stronger power and little air pollution and decreases the operation cost.

Owner:王长锋

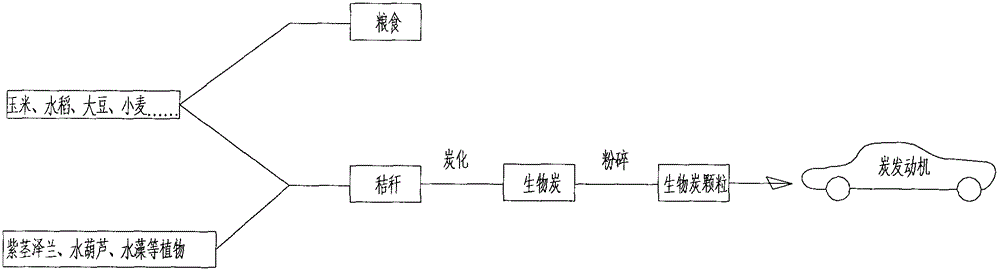

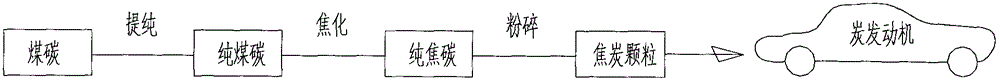

New energy technology

InactiveCN102719261AWide range of raw materialsReduce wasteInternal combustion piston enginesBiofuelsBiodieselNew energy

The invention provides a production and use method of biomass new energy as the biomass new energy serving as renewable energy is wide in prospect. The method includes: carbonizing biomass, performing depth crushing for the carbonized biomass, and then directly using the crushed powdered carbon as fuel of engines. The invention further provides a 'carbon engine' capable of directly using carbon as fuel, and the 'carbon engine' provides a novel direction for design and development of future engines. Besides the developmental directions of biodiesel and bioethanol, the new energy technology provides a novel developmental direction for development of the new biomass energy.

Owner:李明生

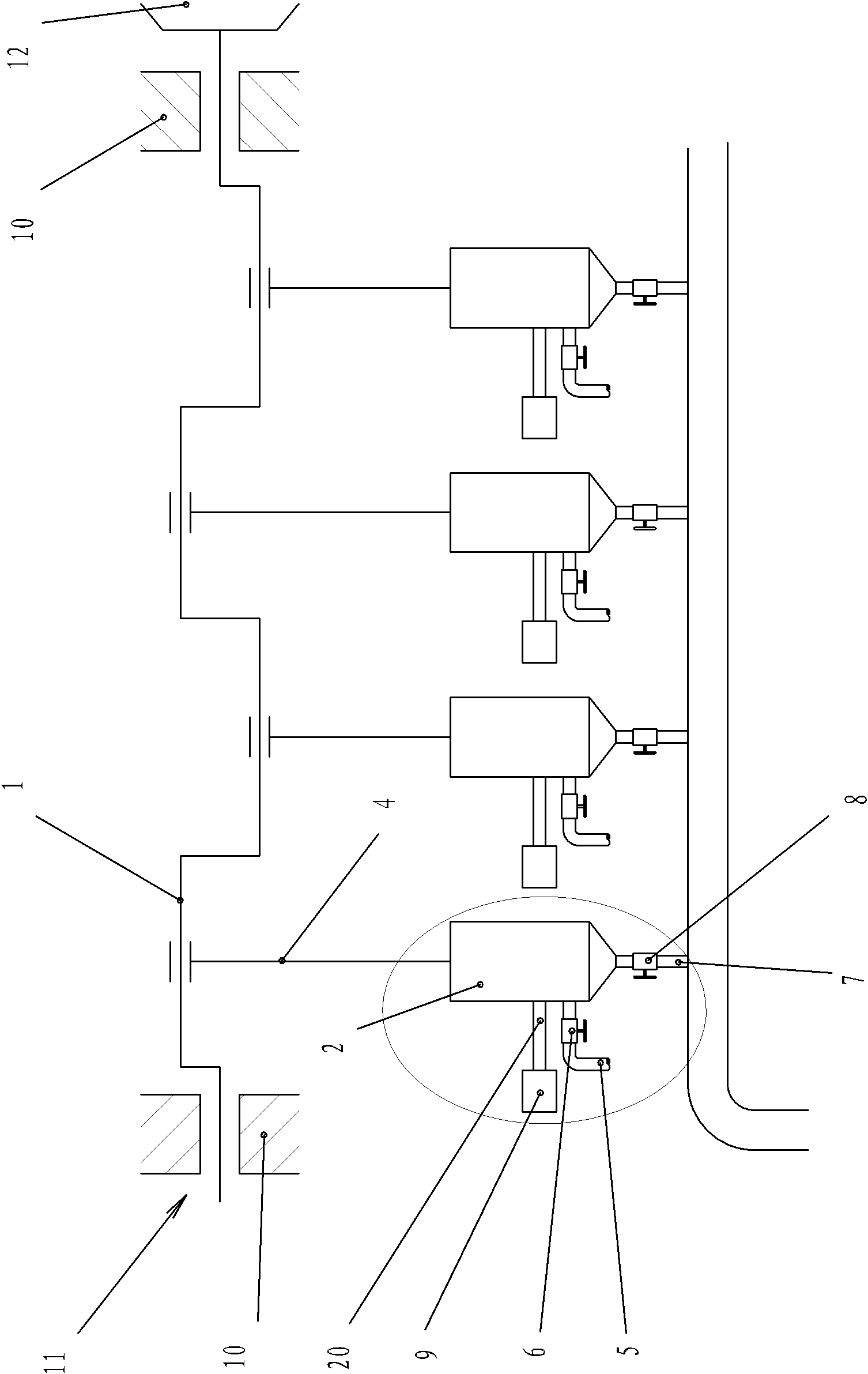

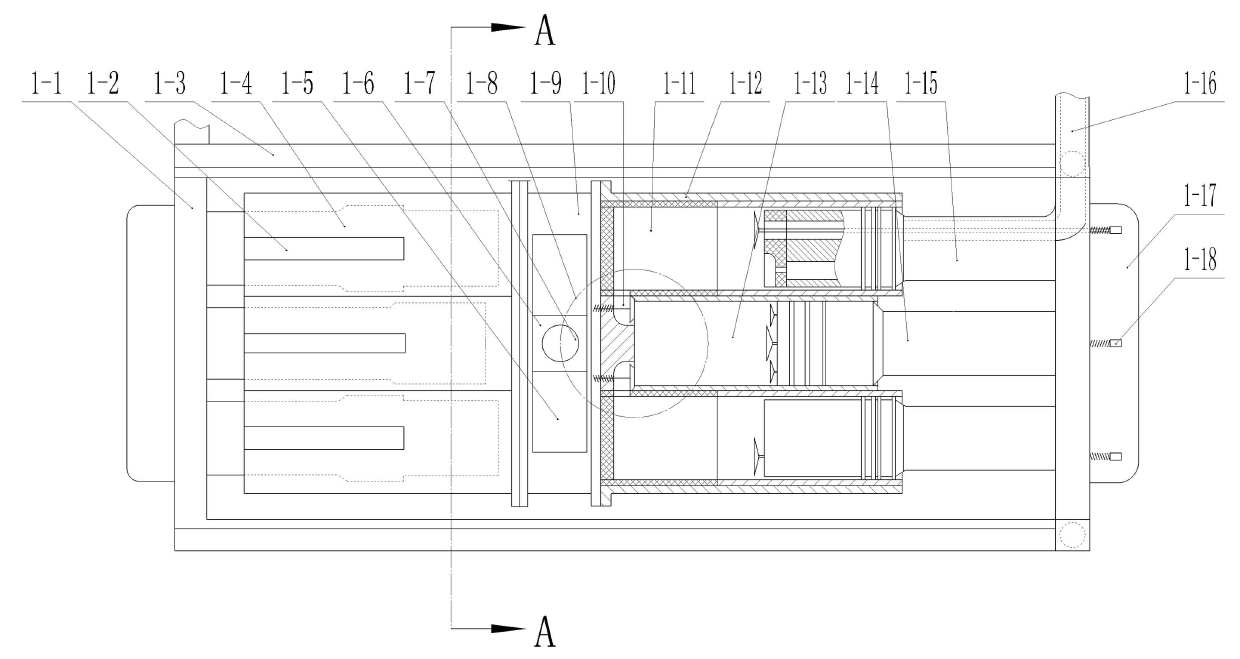

Coal-fired powder internal-combustion engines and generator capable of regulating and controlling generated energy

The invention relates to coal-fired powder internal-combustion engines. Each engine comprises crankshaft, at least one cylinder body and a piston arranged in each cylinder body, wherein each piston is connected with the crankshaft through a crankshaft connecting rod; the lower part of each cylinder body is connected with an inlet of an air coal powder input pipe, and a feed valve is connected to the air coal powder input pipe in series; the bottom of each cylinder body is connected with an outlet of exhaust gas coal ash eliminating pipe, and a blow-off valve is connected to the exhaust gas coal ash eliminating pipe in series; an ignition device is arranged at the lower part of each cylinder body; an ultrasonic launcher capable of launching ultrasonic waves towards each cylinder body is arranged on each piston or at the bottom of each cylinder body. A generator capable of regulating and controlling generated energy comprises a plurality of coal-fired internal-combustion engines; and crankshafts of the plurality of coal-fired internal-combustion engines are arranged coaxially side by side; the adjacent crankshafts are connected by adopting a clutch to form a power shaft; and one end of the power shaft is in transmission connection with an input shaft of the generator. The invention aims to provide the coal-fired powder internal-combustion engines and the generator capable of regulating and controlling the generated energy, which have the advantages of oil resource conservation and high conversion rate of energy sources.

Owner:孟金来

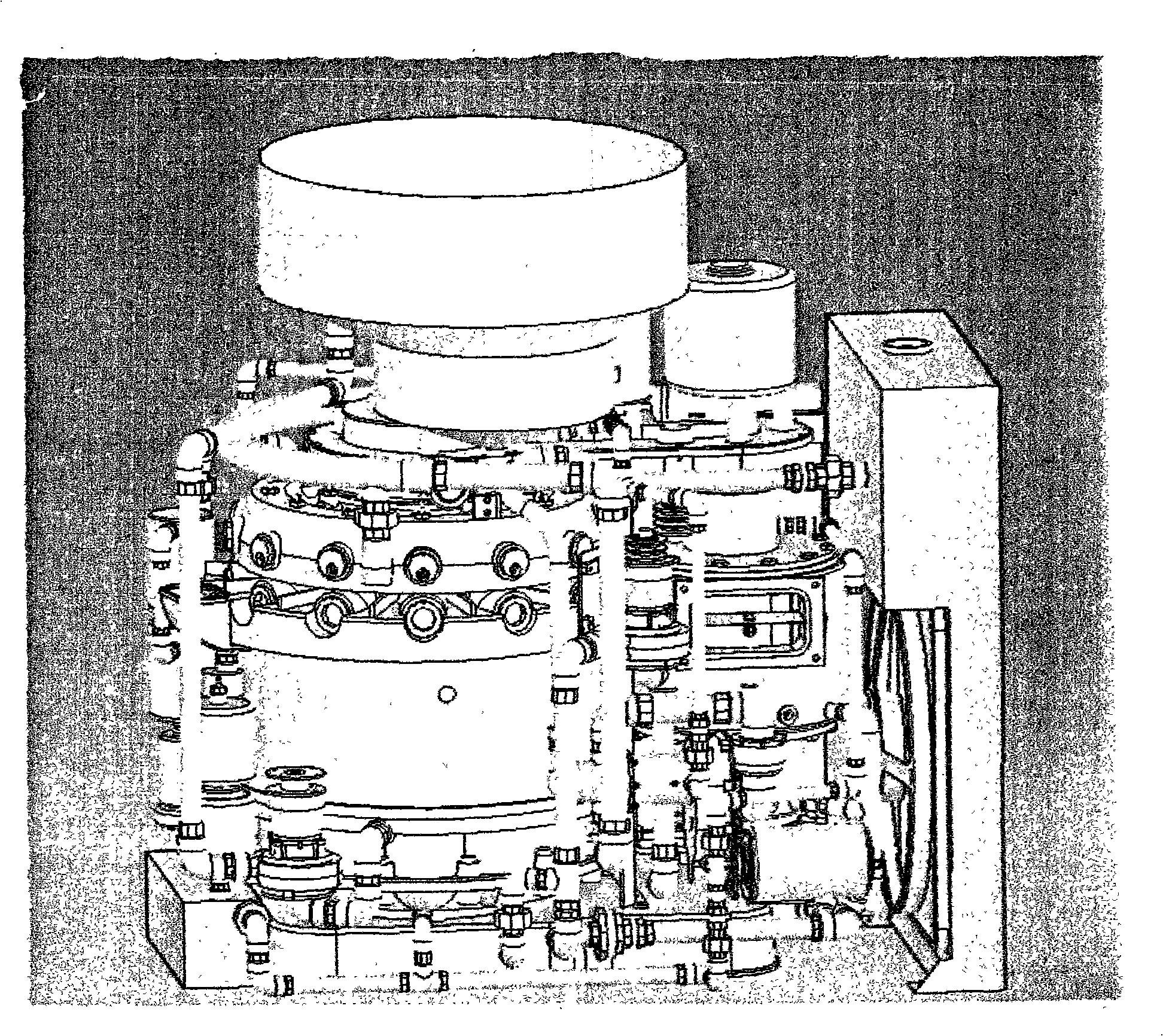

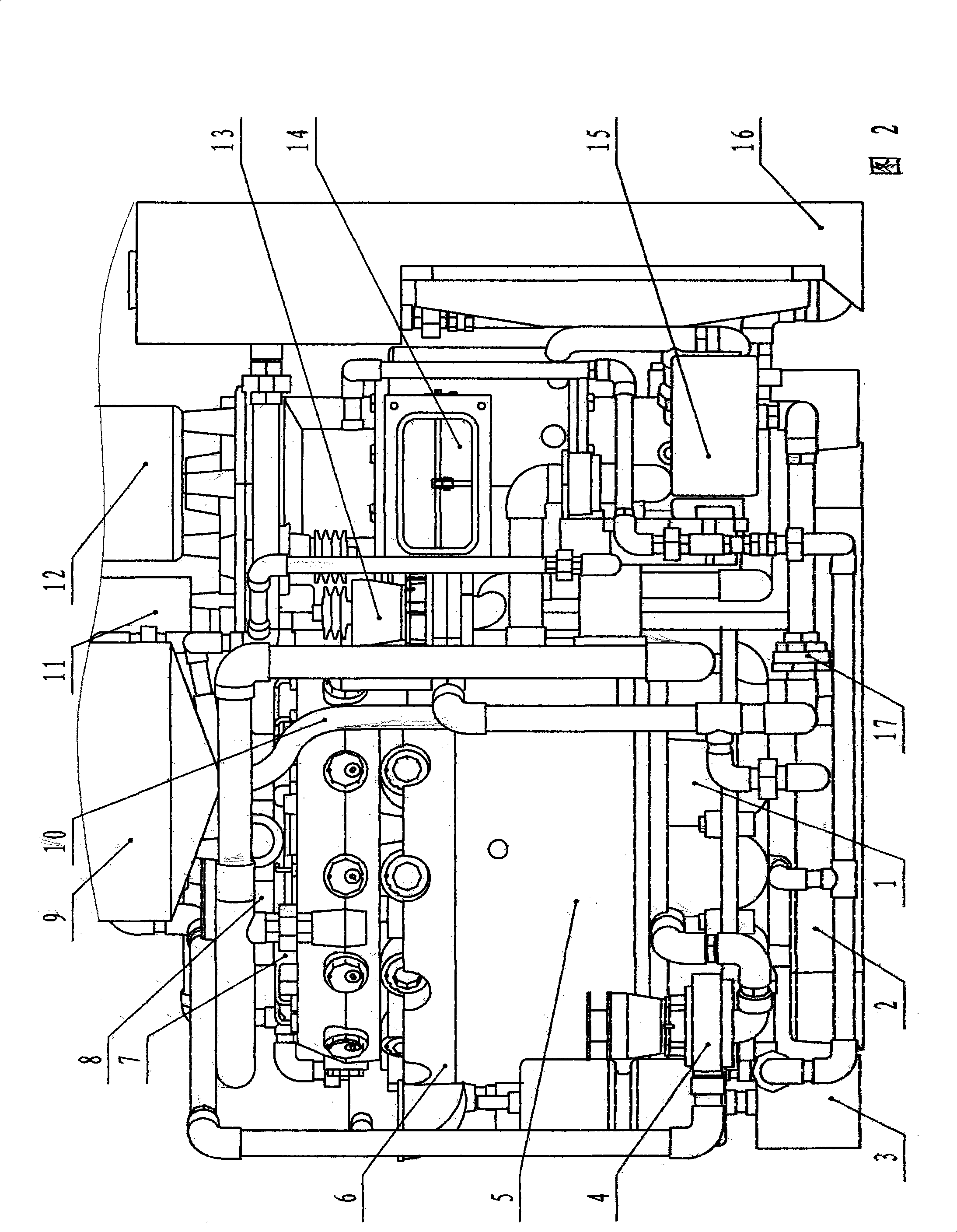

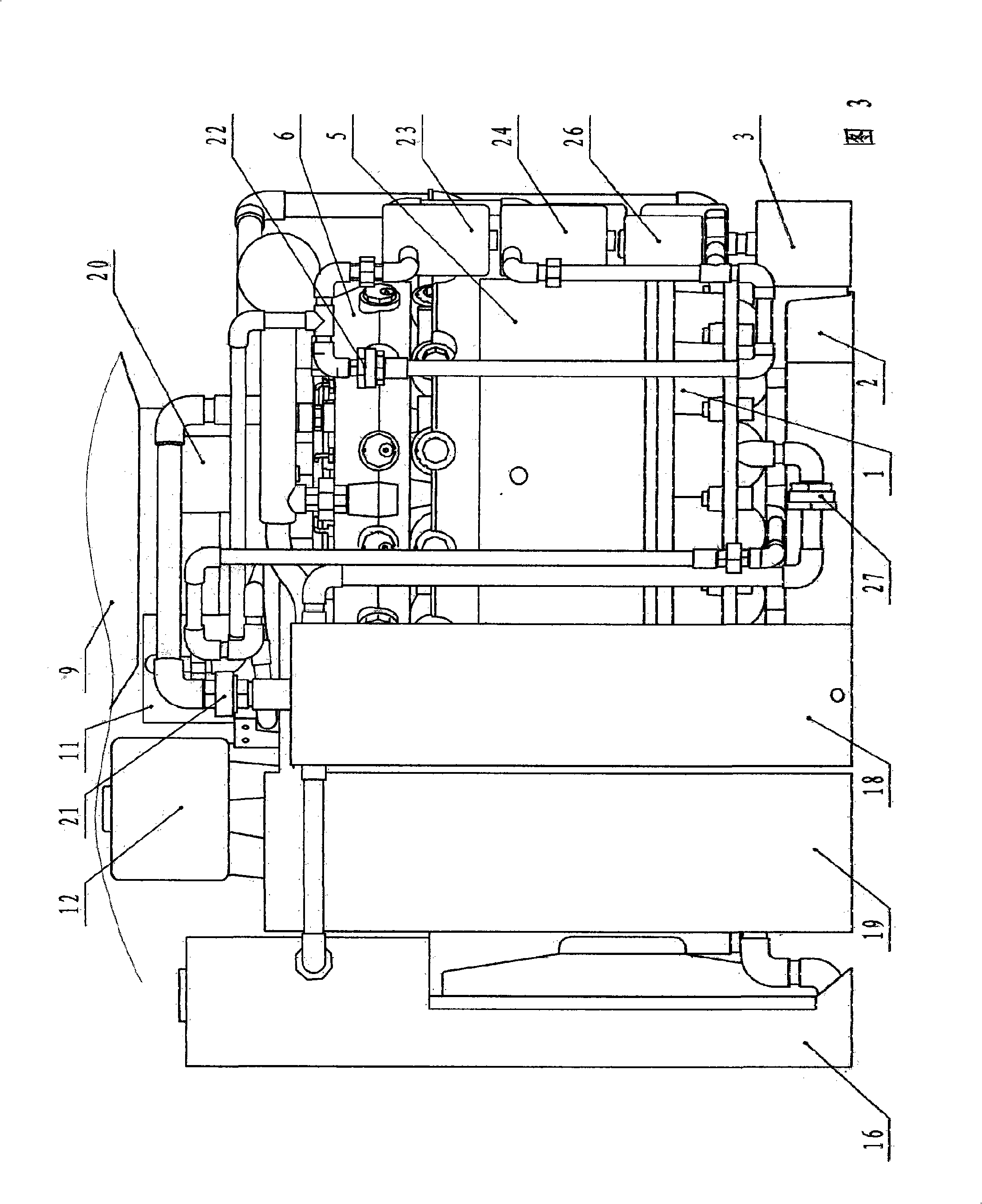

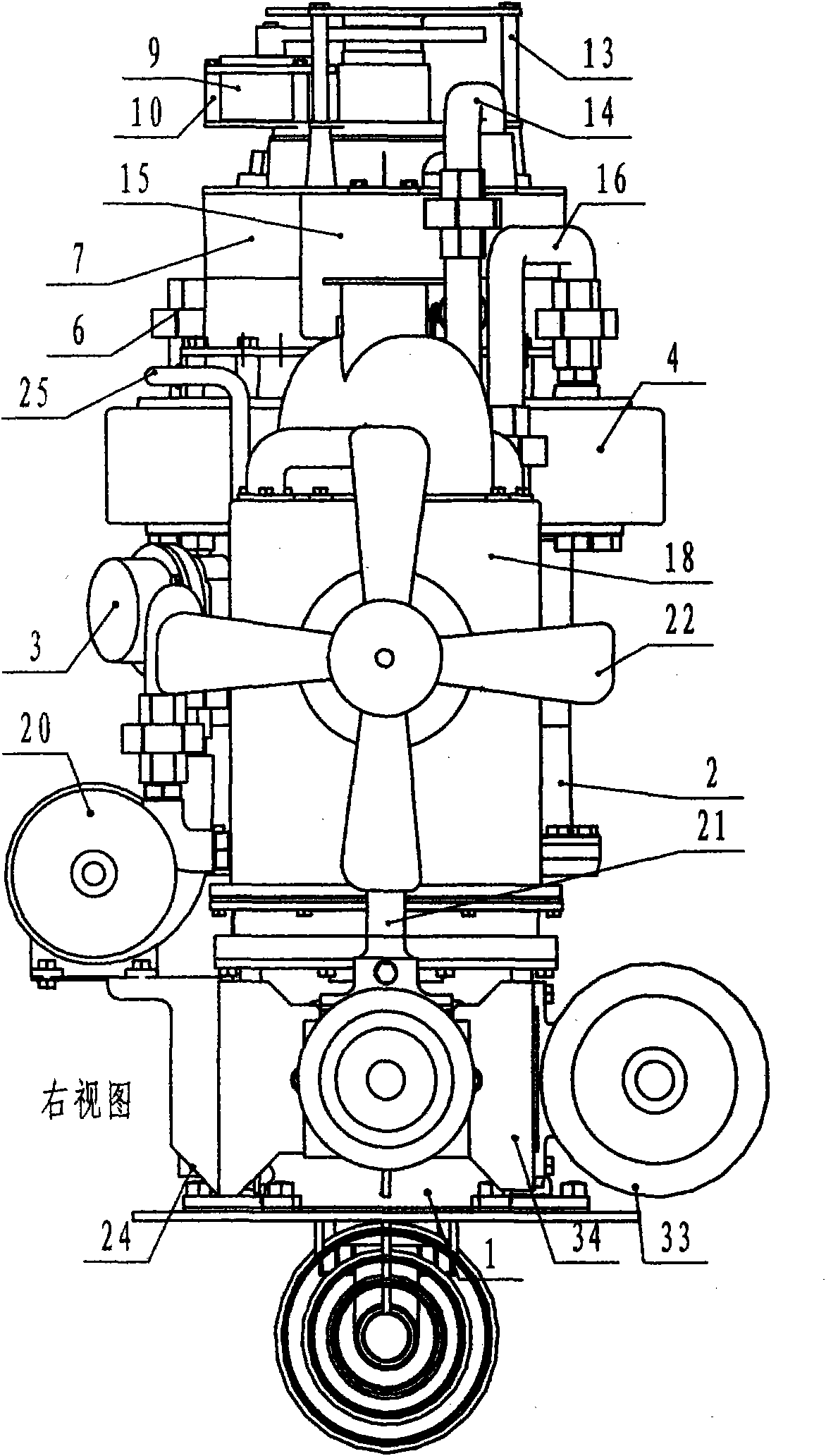

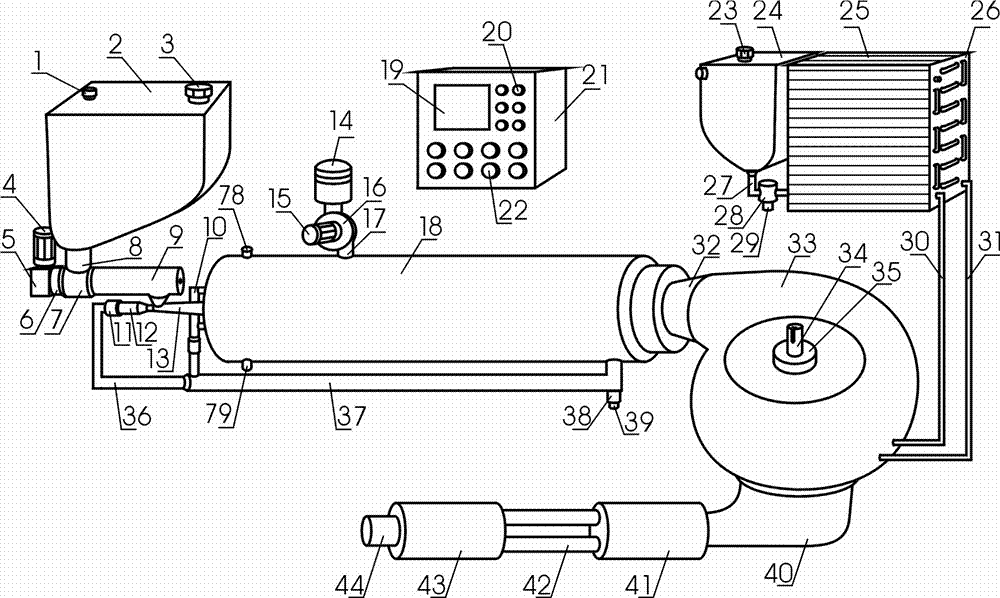

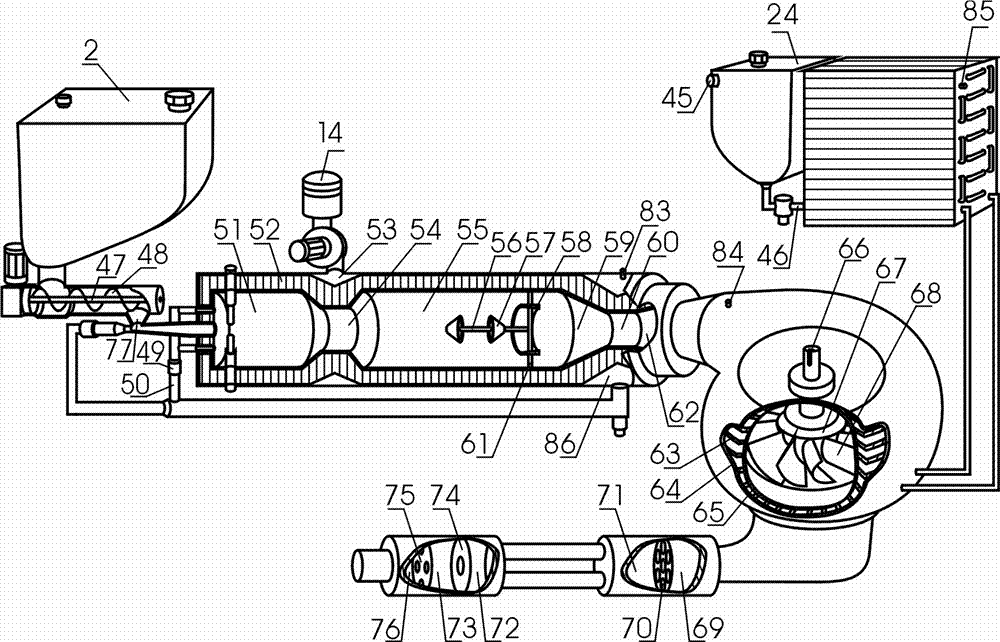

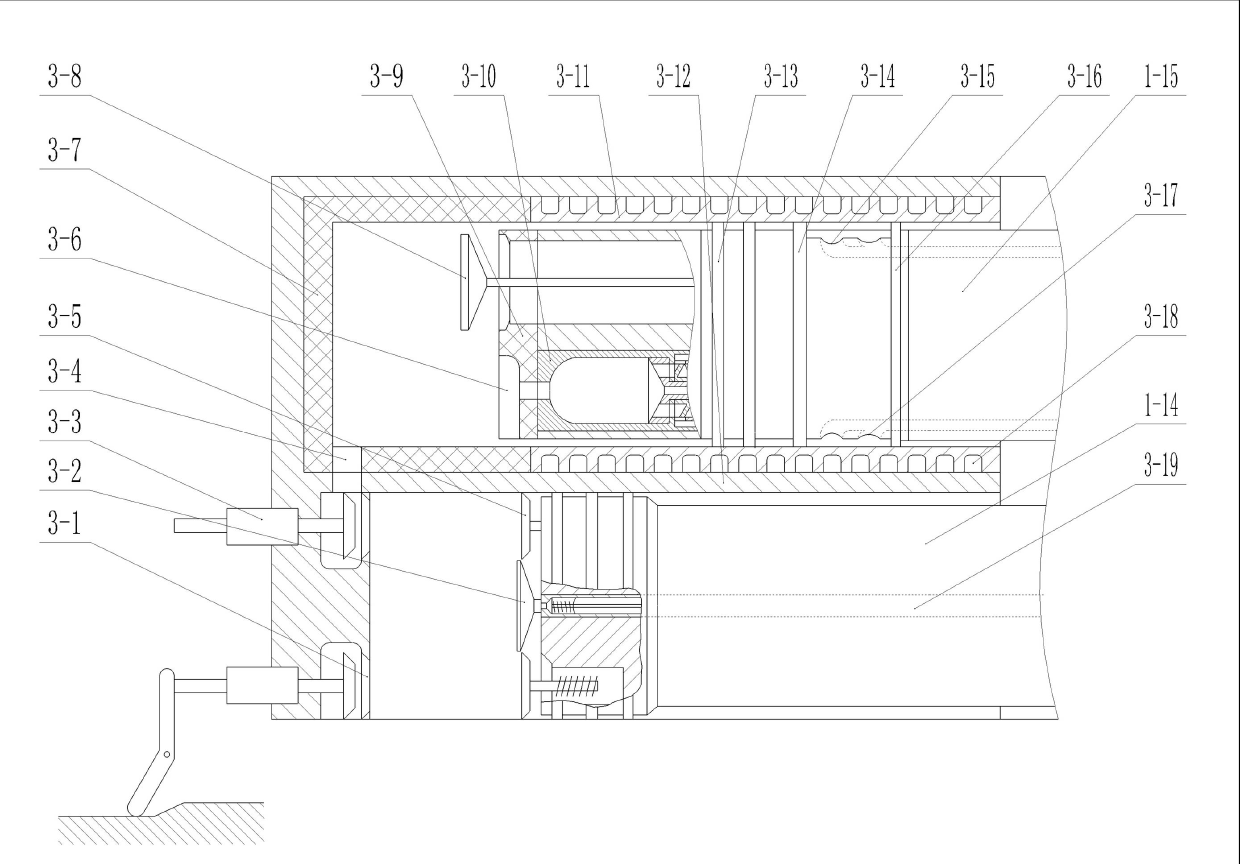

Turbocharged powder internal combustion engine

ActiveCN107387233AStable functionEasy to operateInternal combustion piston enginesEngine controllersCombustorExternal combustion engine

A turbocharged powder internal combustion engine is formed by a fuel tank, a rotary feed pipe, a fuel spray cylinder, a combustor, a draught fan, combustion-supporting gas inlet pipes, a turbocharger, an L-shaped exhaust pipe, a radiator, a water tank and a control box. Various kinds of biomass powder and metal powder with active chemical properties can be combusted, and intelligentized microcomputer control is adopted. The turbocharged powder internal combustion engine is stable in performance, convenient to operate, high in work efficiency, high in torque and steady in output. The turbocharged powder internal combustion engine is a novel internal combustion engine using powdered fuel and can replace an internal combustion engine combusting gas and liquid, and a new approach of replacing fossil energy with clean fuels is created.

Owner:雷学军

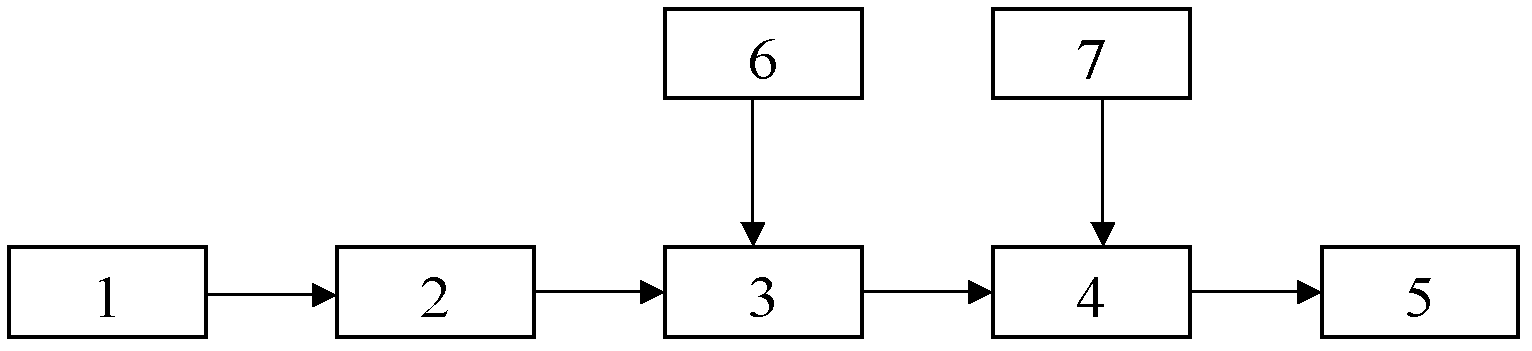

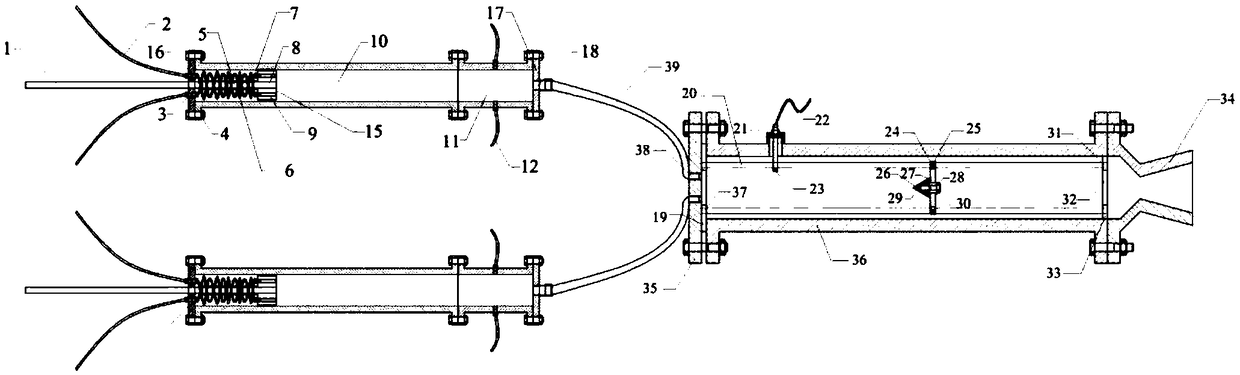

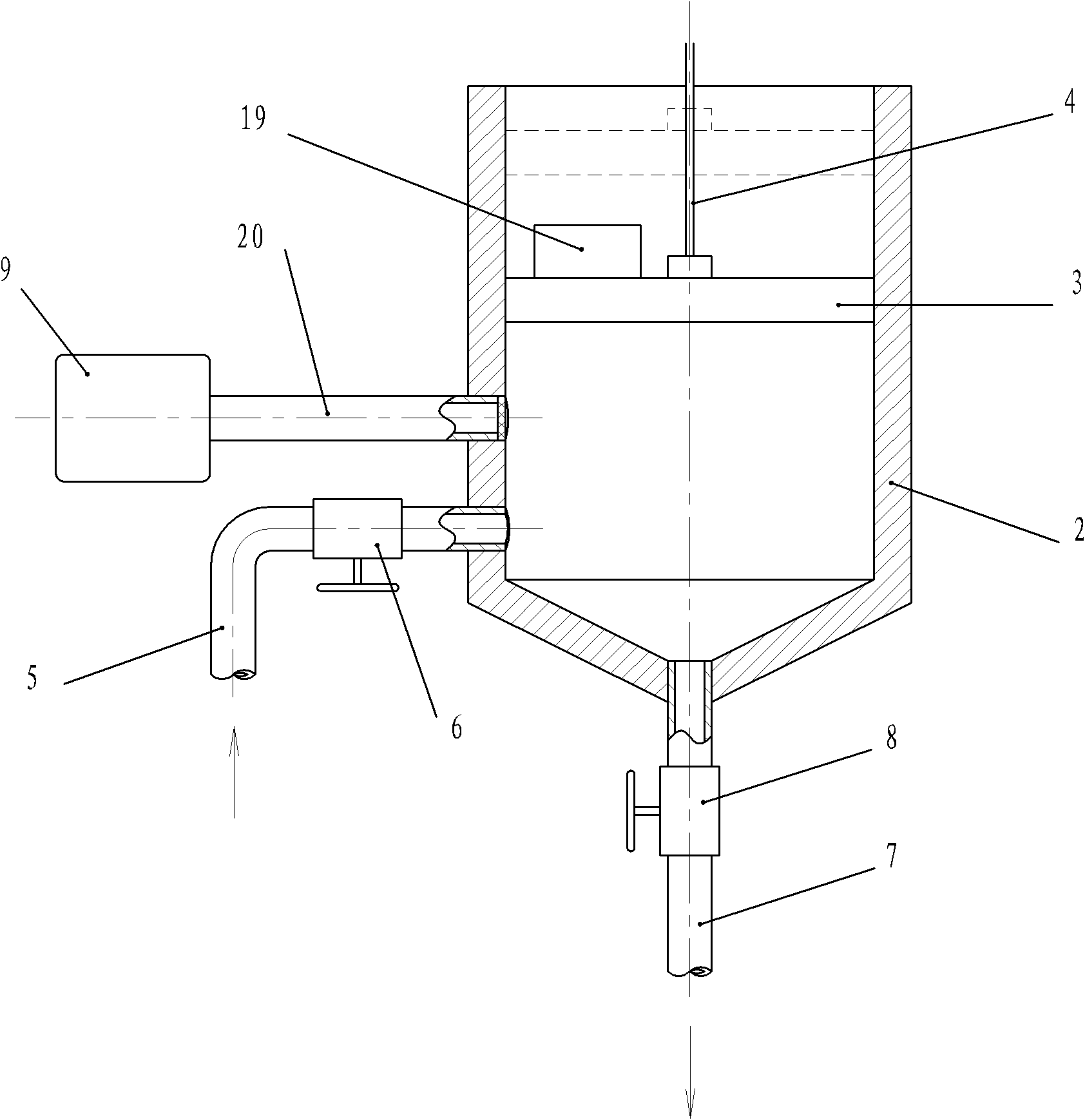

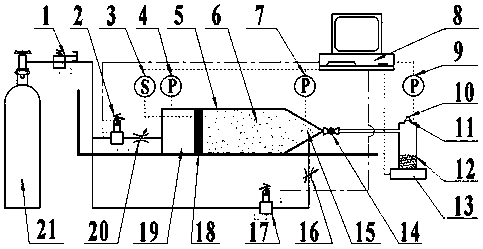

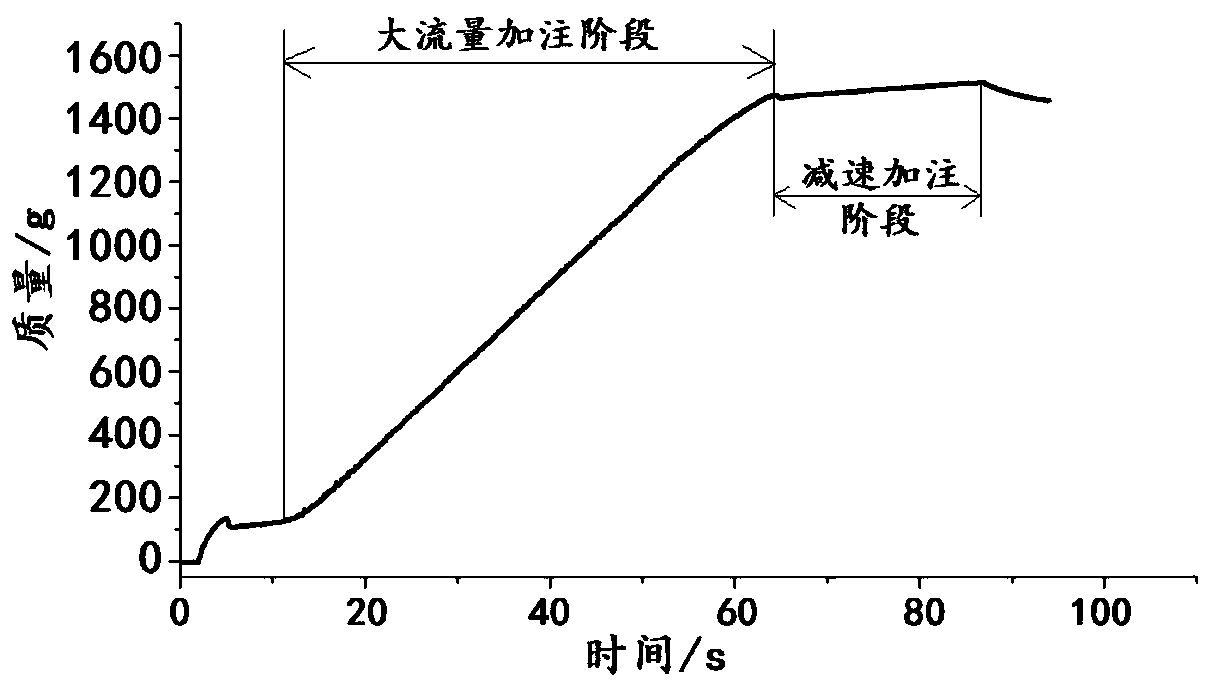

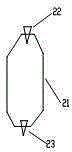

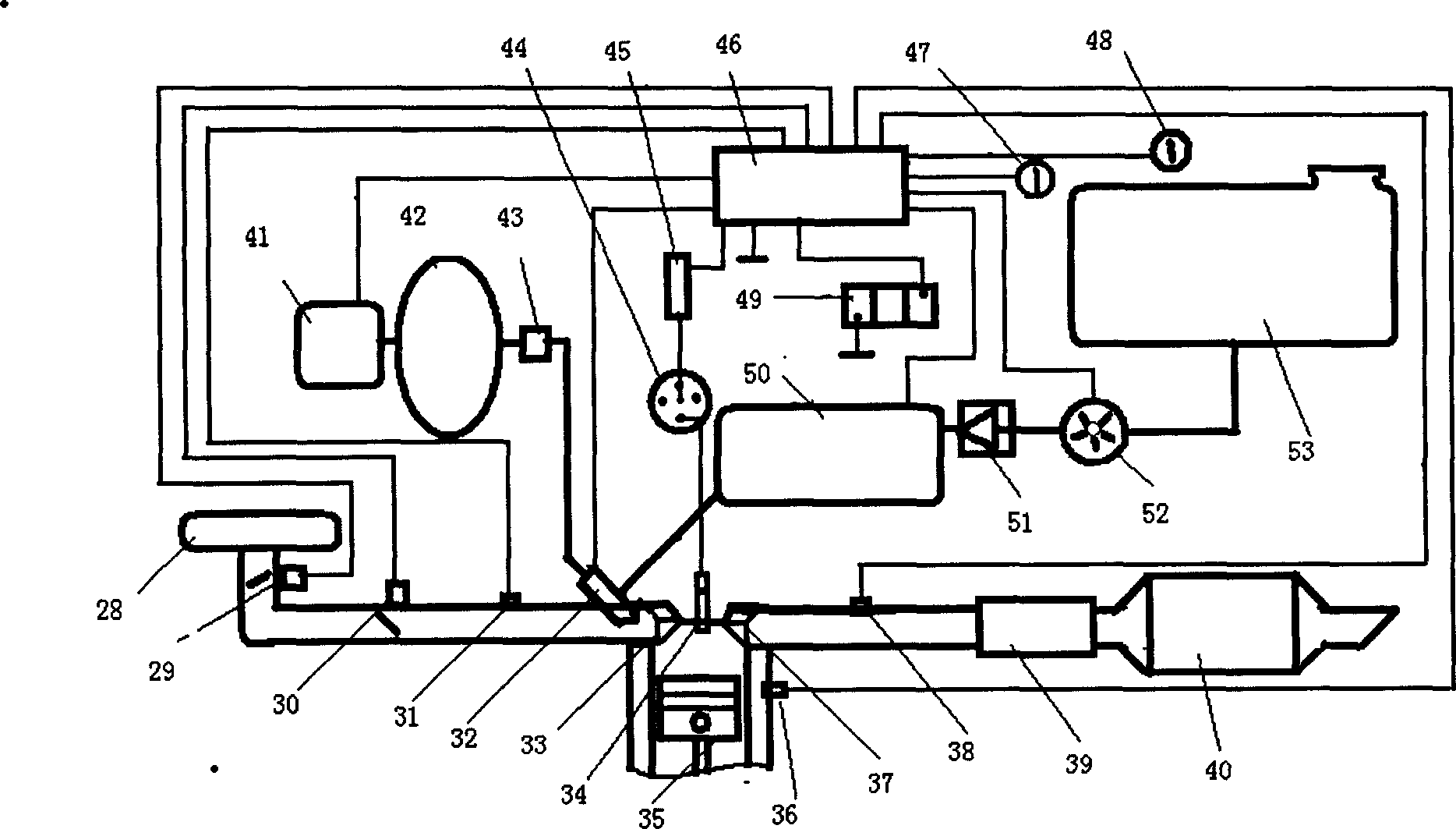

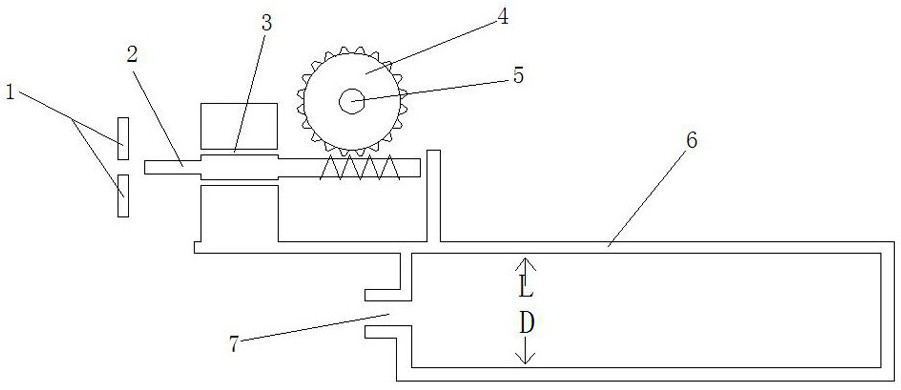

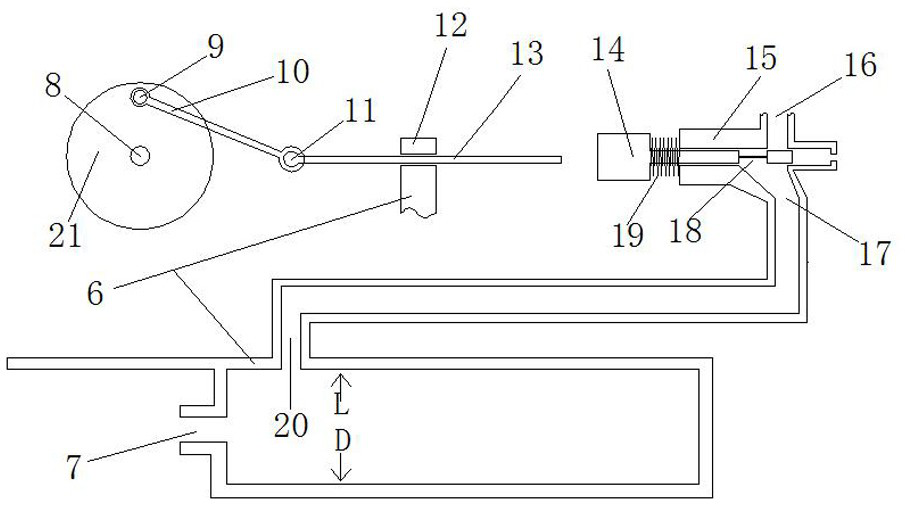

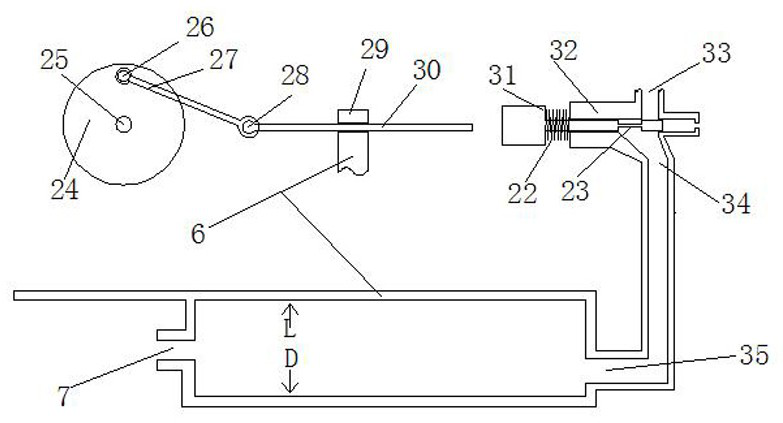

Pneumatic filling method and system for powder particles

ActiveCN109779743AAvoid wastingGuaranteed cleanlinessInternal combustion piston enginesPowdered engine fuelsGas cylinderProduct gas

The invention discloses a pneumatic filling system for powder particles. The pneumatic filling system comprises a storage box, a gas cylinder and a powder box; the storage box is a cylindrical body; the front end of the storage box is in the shape of a cone; a piston is coaxially sleeved with the storage box; the inside of the storage box is divided in the axial direction from front to back into afluidization cavity and a driving cavity which are arranged independently; a powder outlet is formed in the front end of the fluidization cavity and is in pipeline connection with the powder box; thecone at the front end of the fluidization cavity and the back end of the driving cavity are in pipeline connection with the gas cylinder; the driving cavity and the fluidization cavity are filled with gas inside the gas cylinder; the gas entering the driving cavity drives the piston to push the powder particles inside the fluidization cavity to move forwards, and meanwhile, the powder particles is fluidized in the gas by the aid of the gas entering the fluidization cavity, so that the gas-solid two-phase gas flow is formed and flows into the powder box via the powder outlet. Safe powder supply to the fuel powder box is realized, and the filling rate of the powder box is up to 97%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

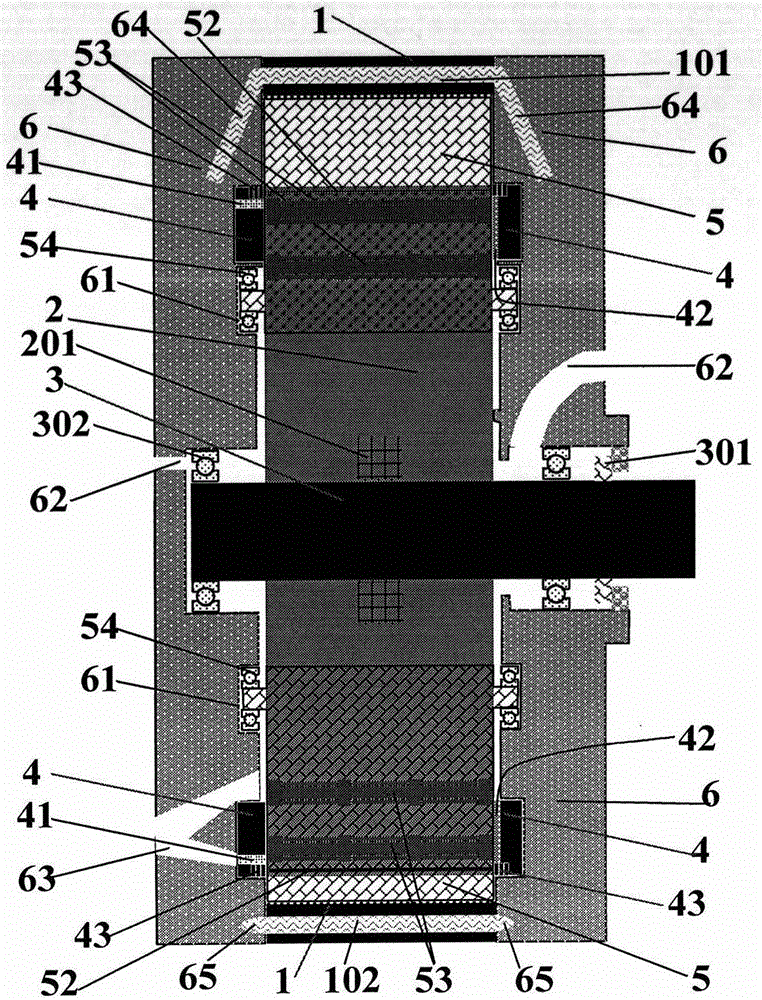

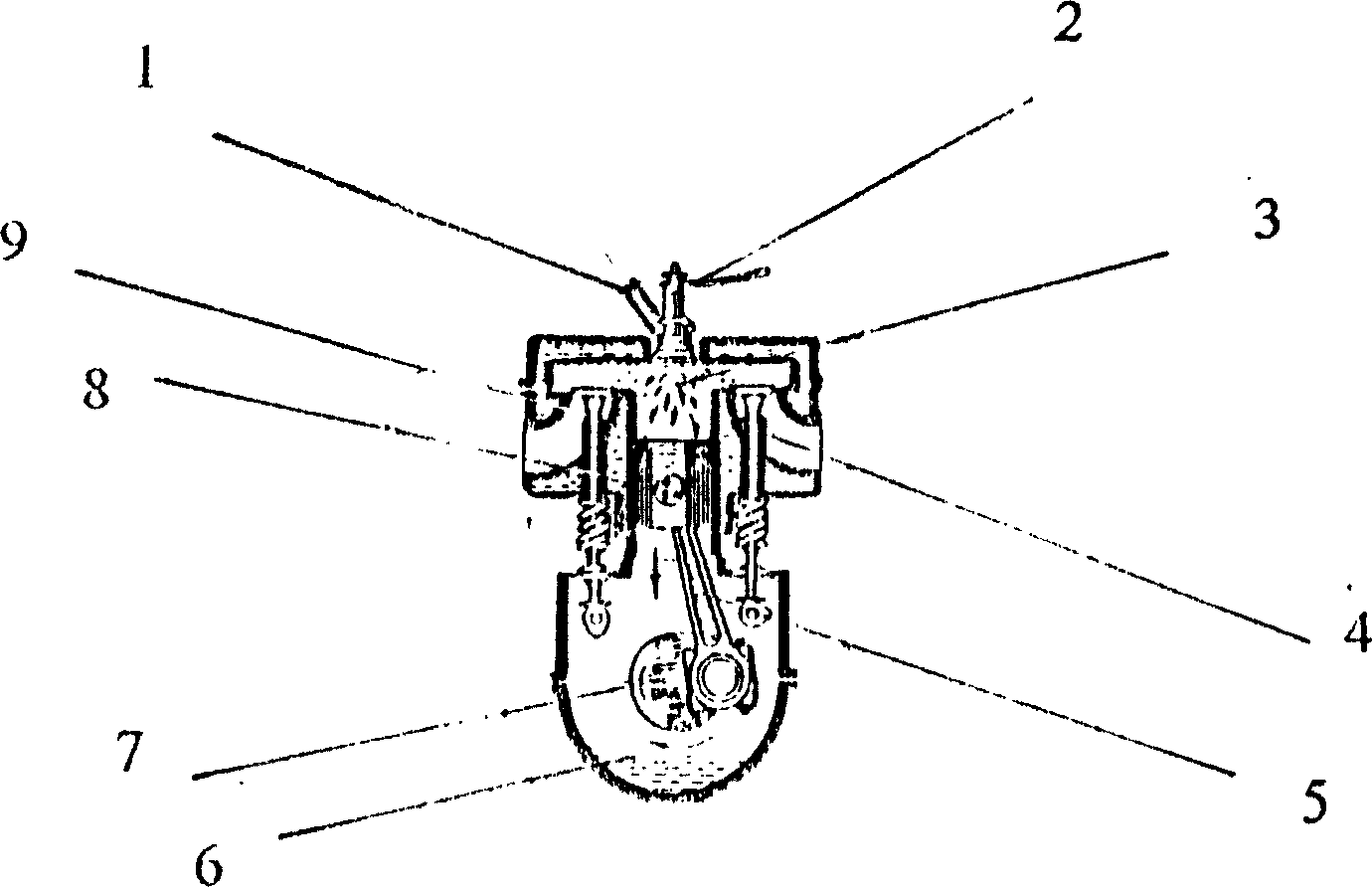

Bistroke ignition type combustible particle internal combustion engine

InactiveCN1904323AIncrease temperatureIncrease pressureInternal combustion piston enginesPowdered engine fuelsExhaust valveCombustion

The invention uses combustible particles as a main fuel and adopts priming ignition, i.e. sets an ignition chamber to ensure the ignition of the combustible particle fuel. One operating cycle of the inventive internal combustion engine finishes by two strokes, the exhaust stroke and the work stroke. The piston during the work stroke can move from the top dead center to the bottom dead center in order of four process of suction, jetting the fuel, ignition and combustion. The invention consists of an ignition chamber, a fuel nozzle, a cylinder, an exhaust valve, a connecting-rod, a crankshaft, a crankcase, a piston and an air intake valve.

Owner:成都安捷网际服务有限公司

Later-compression-stroke carbon filling type carbon powder engine

InactiveCN104196619AEase the crisisDepletion rate reducedInternal combustion piston enginesPowdered engine fuelsCombustion chamberNew energy

The invention discloses a later-compression-stroke carbon filling type carbon powder engine, and belongs to the field of internal combustion engines. The engine has a spark ignition type and a compression ignition type. Petroleum resources are exhausted day by day, and therefore it is imperative that renewable resources are utilized for replacing petroleum to become new energy sources. It is a feasible idea that carbon powder is utilized for solving the problem. It is a pity that many defects still exist in the carbon powder engine in the aspect of the internal combustion engines, for example, the combustion rate is low, power output is unstable, and carbon powder blocks piston motion, and the problems are urgently needed to be solved. Various problems of the carbon powder engine are solved by changing the carbon filling mode, a combustion chamber, the ignition mode and the like of the carbon powder engine. The engine can be used as a device capable of converting chemical energy of carbon into mechanical energy and can be used for power generation of the carbon powder internal combustion engines, an automotive carbon powder engine and the like.

Owner:李松

Common rail supplementary atomizer for piston engines

InactiveUS7418927B2Rapid and completeIncrease effective viscosityInternal combustion piston enginesNon-fuel substance addition to fuelCommon railSlurry

A common rail supplementary atomizer of this invention, when used on a piston internal combustion engine, equipped with a common rail fuel injection system, improves slurry atomization, following injection, by expansion of gases, previously dissolved in the water phase of the slurry. This gas expansion separates the several fuel particles in each slurry droplet formed first during fuel injection. The thusly separated fuel particles subsequently burn more rapidly and completely, due to this fuel particle separation improving air access to the fuel. Apparatus is described for dissolving atomizing gas into the water phase of the slurry, in a contactor chamber at a pressure greater than the pressure prevailing in the engine cylinder volume, at the time of slurry injection.

Owner:FIREY JOSEPH CARL

Solid-fuel internal combustion engine

The invention discloses a solid-fuel internal combustion engine. The solid-fuel internal combustion engine consists of a combustion chamber, an air inlet system, a feeding system, a working system and a slag discharging system, wherein the air inlet system is connected with the combustion chamber, and is responsible for supplying compressed air to the combustion chamber; the feeding system is connected with the combustion chamber, and is responsible for conveying solid fuel to the combustion chamber; the size of the combustion chamber is constant; the solid fuel is continuously combusted in the combustion chamber, high-temperature high-pressure gas and solid waste slags are generated; the working system is connected with the combustion chamber, and the working system converts the internal energy of the high-temperature high-pressure gas into mechanical energy to be output outsides; the slag discharging system is connected with the combustion chamber, and is responsible for discharging the waste slags generated in the combustion chamber out of the internal combustion engine.

Owner:周虎

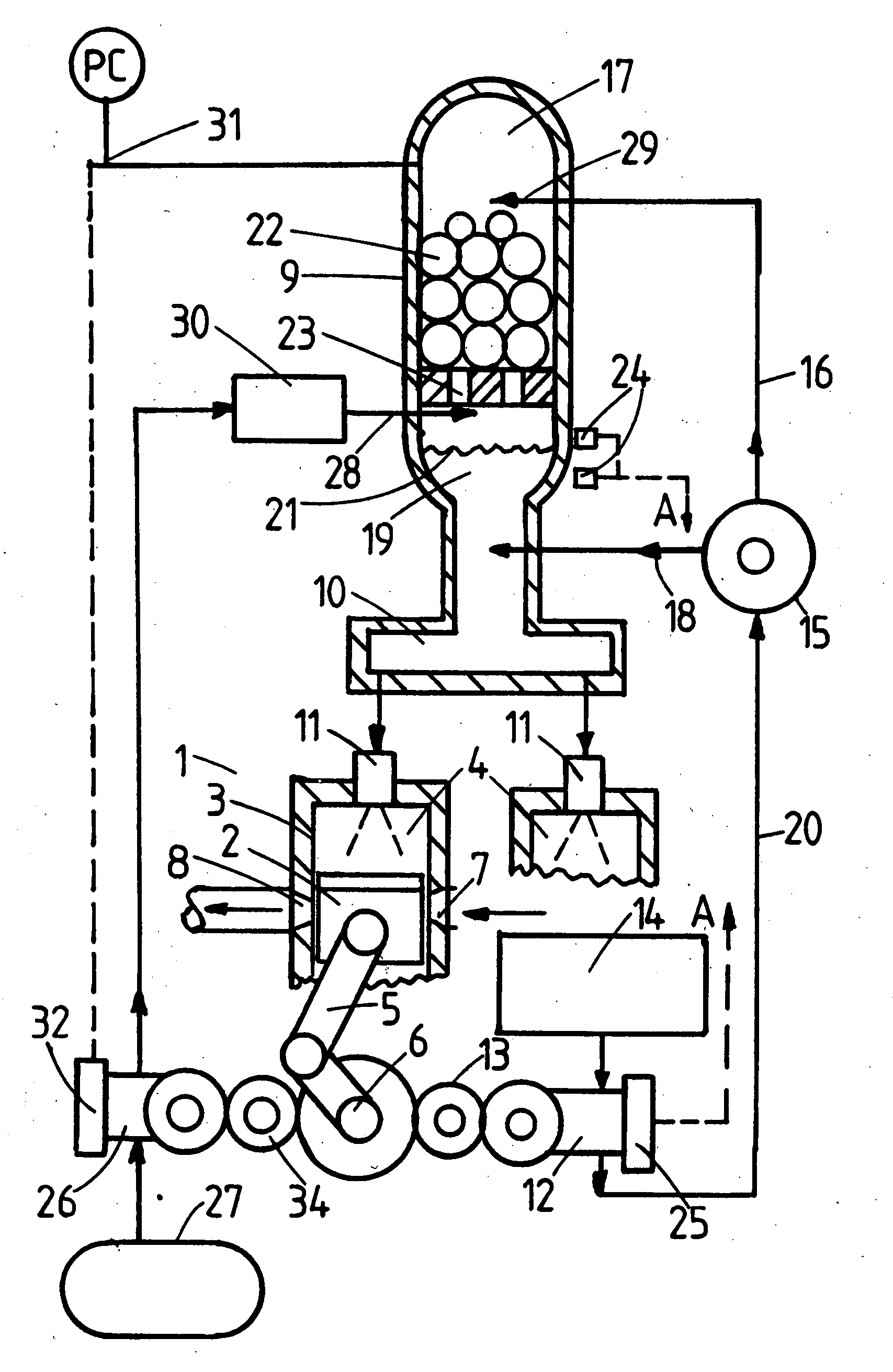

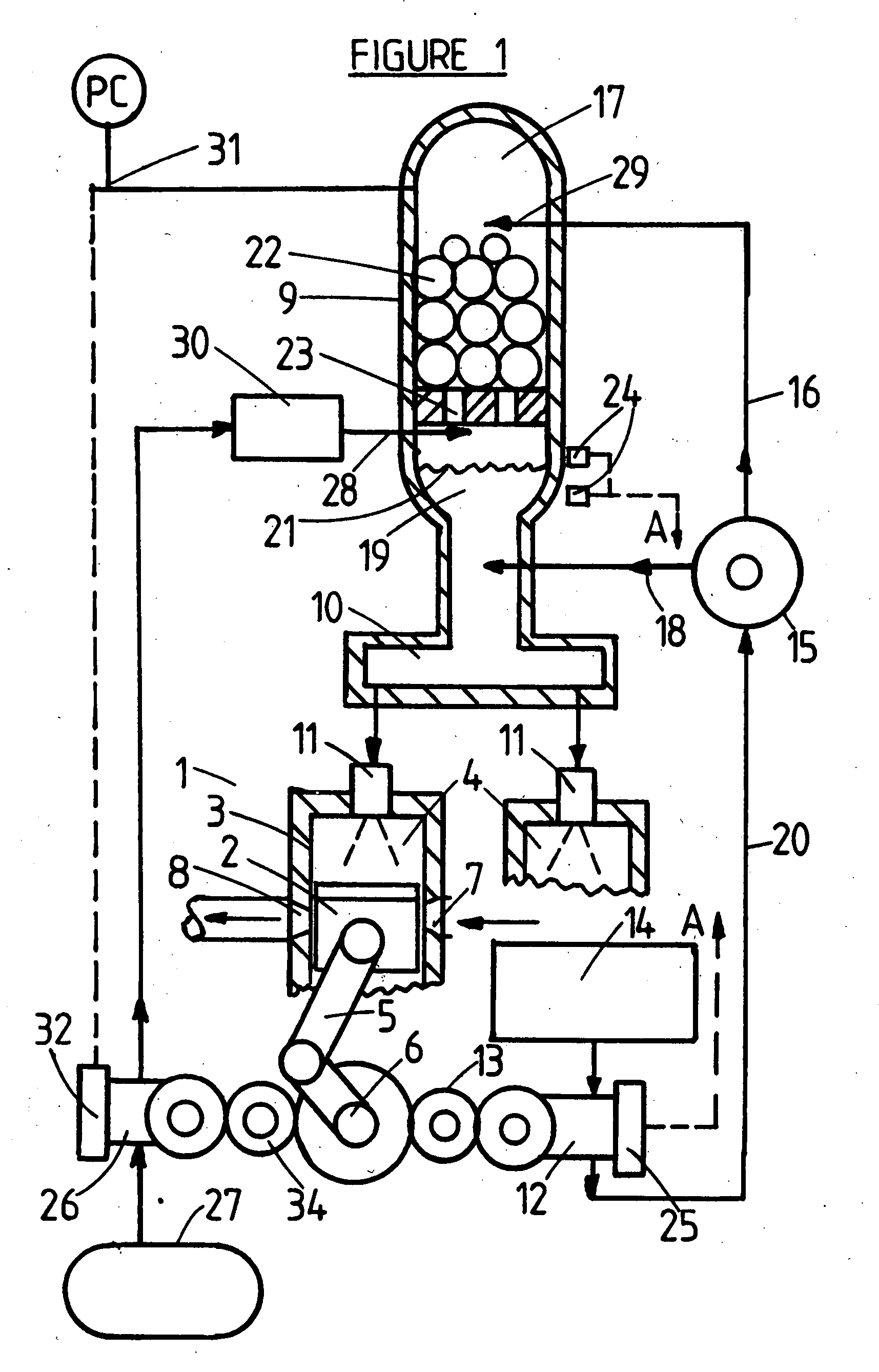

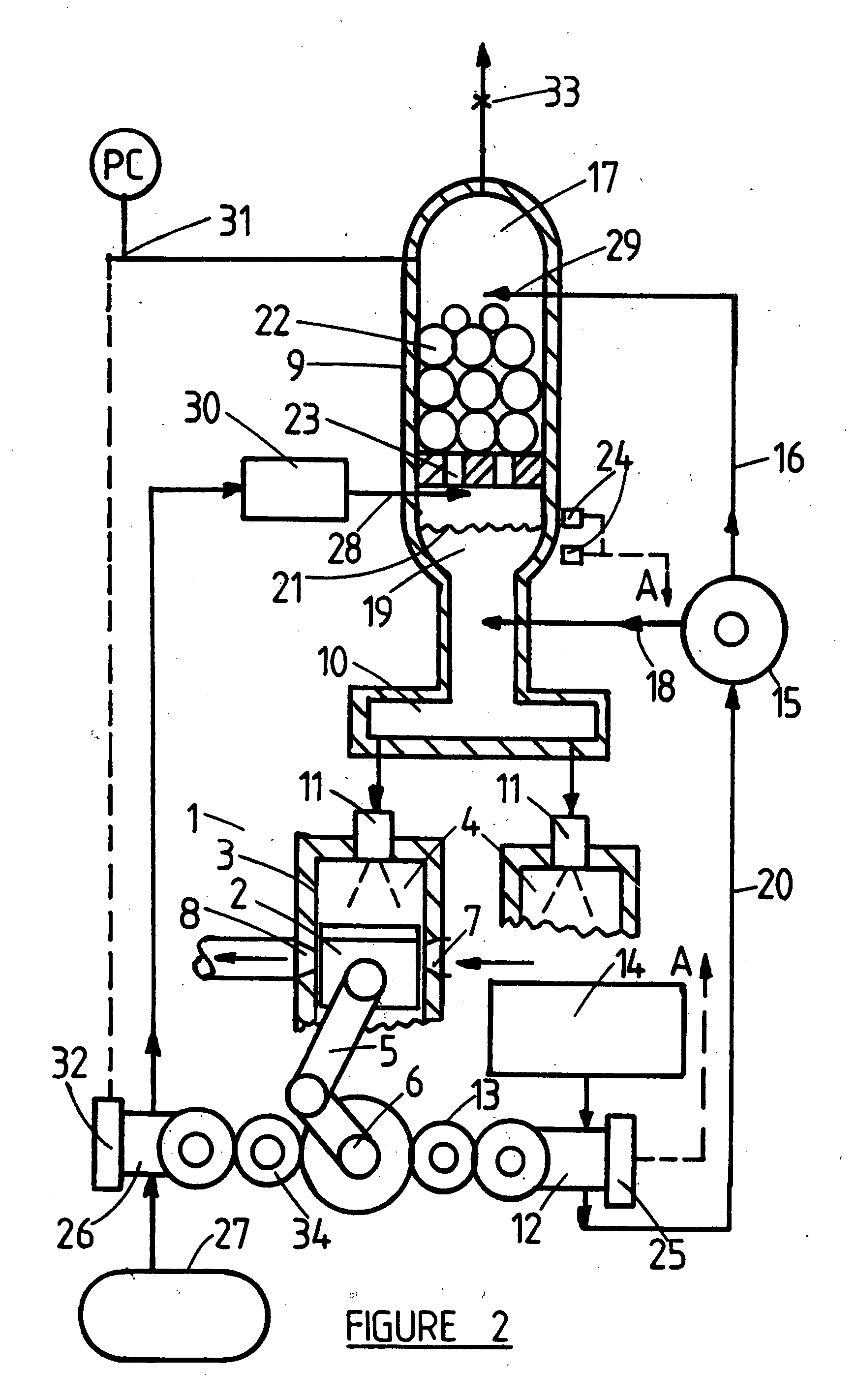

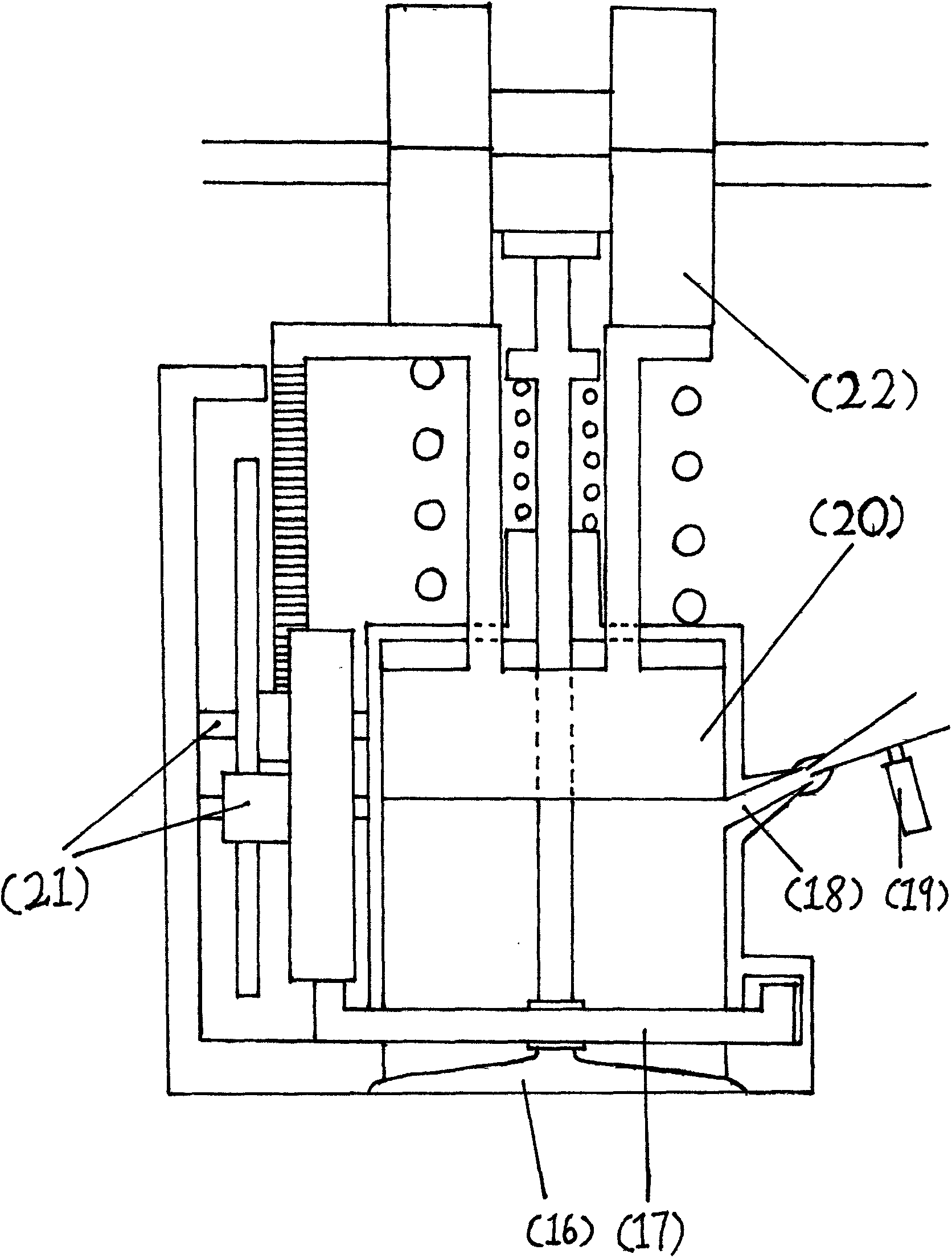

Powder fuel engine

InactiveCN102635438AImprove utilization efficiencyImprove use valueInternal combustion piston enginesFuel supply apparatusLower gradeTar

The invention discloses a powder fuel engine. The powder fuel engine comprises a power system, a fuel supply system, a gas supply system and a dust and tar removal system, wherein a piston in the power system is fixedly connected with a machine body; a cylinder is connected with a power output mechanism; a fuel supplying device in the fuel supply system is communicated with a power cylinder in the cylinder; and a tar removing ring in the dust and tar removal system is pressed against the power cylinder. The cylinder is a cylinder unit body and comprises a compression cylinder and the power cylinder, wherein a power piston assembled with the power cylinder is fixedly arranged on the inner side of an end face box of the machine body; a compression piston assembled with the compression cylinder is fixedly arranged on the inner side of the end face box of the machine body; and the cylinder bodies of the power cylinder and the compression cylinder are arranged on a main box of the machine body in sliding fit. The powder fuel engine can use a powder fuel made of straw and coal, so that the utilization efficiency of reproducible fuels such as the straw and the like is increased, and a using method is simplified; the powder fuel engine can be used for providing power for movable transportation equipment, so that the use value of low-grade fuels is promoted; and the powder fuel engine is simple in structure, convenient to manufacture and high in heat efficiency.

Owner:丁健威 +1

Systems for the combustion of aluminum or magnesium powder and the recovery of their products

ActiveCN106939829BAvoid emissionsReduce pollution sourcesInternal combustion piston enginesFuel supply apparatusExternal combustion engineFuel tank

The invention provides a system used for combustion of aluminum powder or magnesium powder and recovery of a product generated during combustion. The system comprises a combustion subsystem, a high-pressure fuel gas automatic compensation and storage subsystem, a cooling subsystem, a product recovery subsystem, an external combustion engine and internal combustion engine combined subsystem and an air compression and compensation storage subsystem. The combustion subsystem comprises a compressed air tank, a fuel tank, a combustion tank and a controller. The compressed air tank and the fuel tank are connected to the combustion tank. A fuel gas storage tank of the high-pressure fuel gas automatic compensation and storage subsystem is connected to the fuel tank. A cooling loop of the cooling subsystem is arranged outside the combustion tank and the fuel gas storage tank. A product collection device of the product recovery subsystem is connected to the combustion tank and the fuel gas storage tank. An internal combustion engine of the plasticization is connected to the fuel gas storage tank. The two ends of an air compressor of the air compression and compensation storage subsystem are connected to the internal combustion engine and the compressed air storage tank correspondingly. According to the system, metal powder fuel is adopted, high-pressure gas can be generated in an external combustion engine to drive a machine to act, and energy saving and environmental friendliness are achieved.

Owner:熊朔

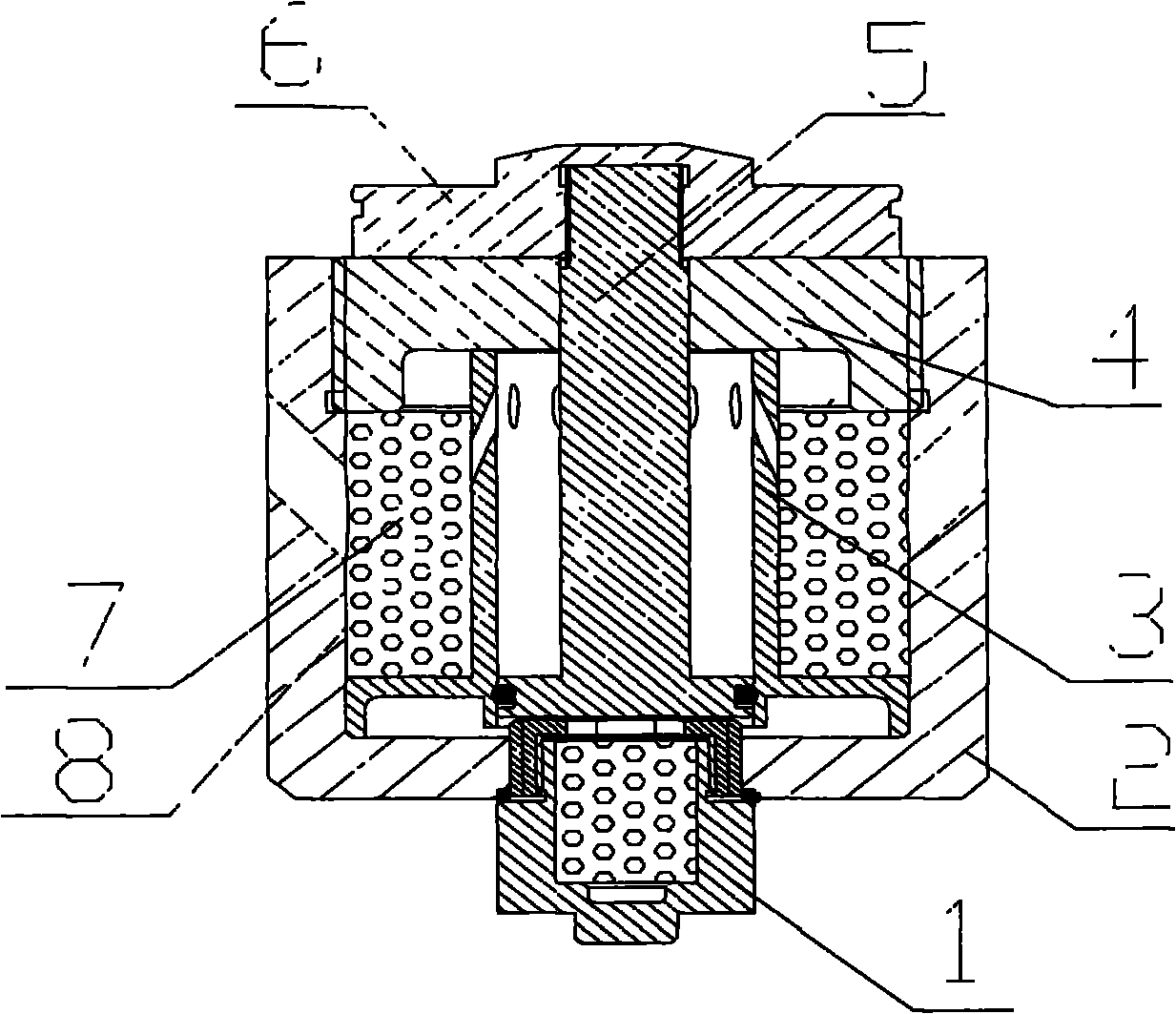

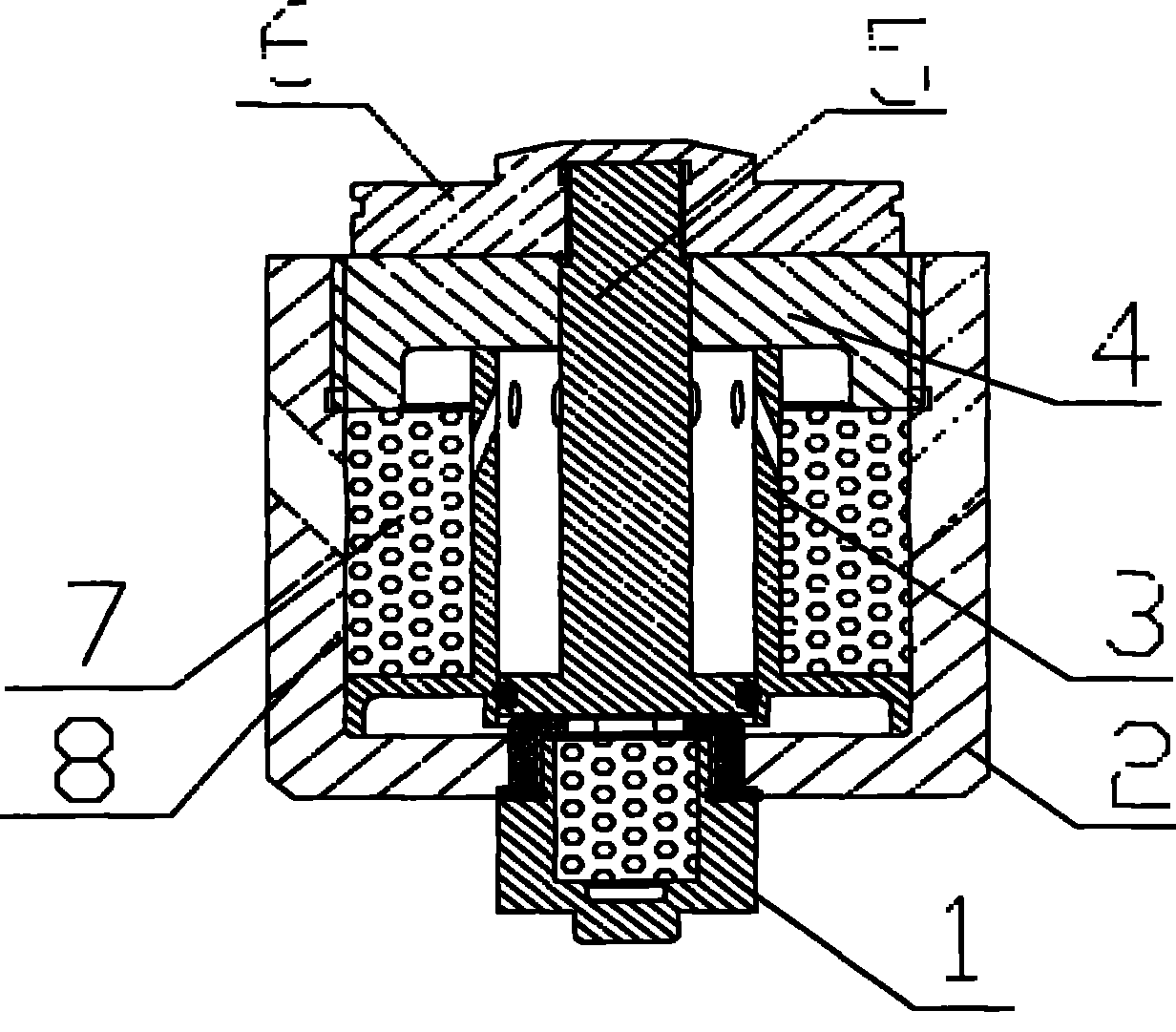

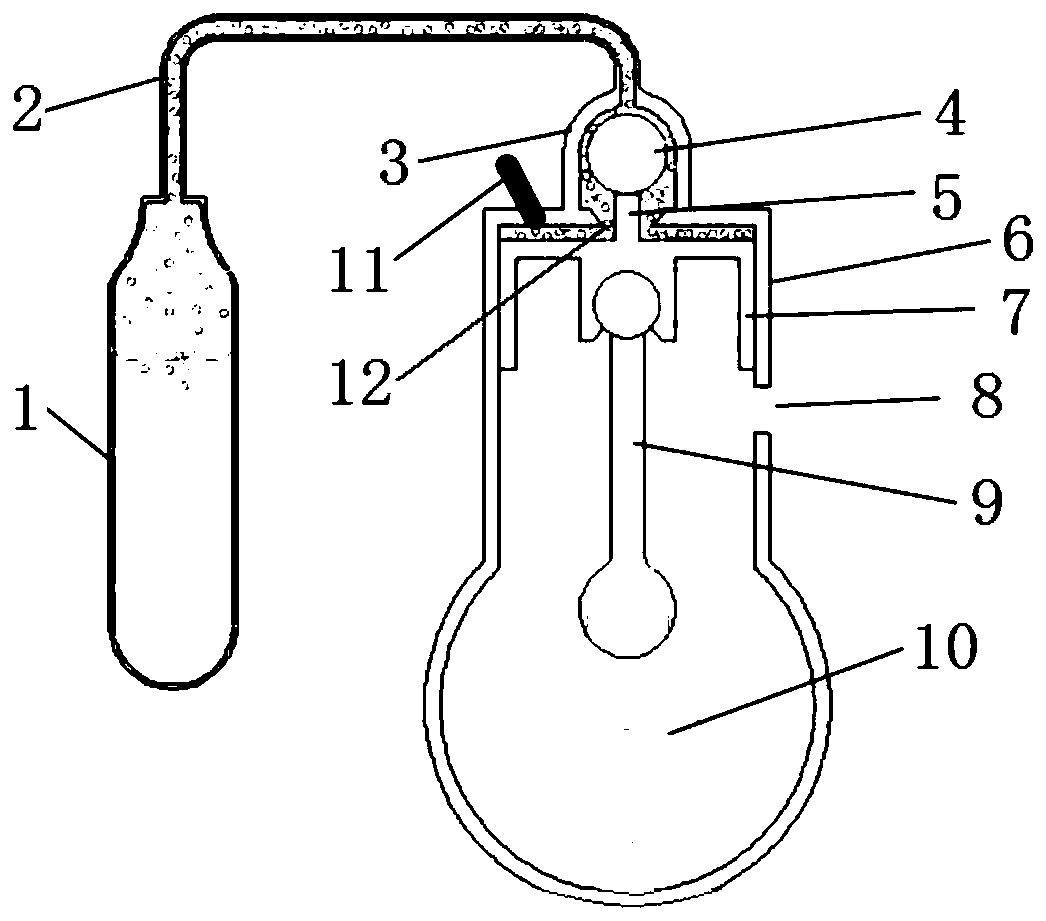

Piston movement and ignition separated gas power device

The invention discloses a piston movement and ignition separated gas power device comprising an igniter (1), a casing (2), a piston top cover (4), a piston rod (5), a piston head (6), main charge (7), a main charge box (8) and a gas separation sleeve (3), wherein the igniter (1) is in threaded connection with the casing (2); the piston rod (5) is arranged in the gas separation sleeve (3); the main charge (7) is arranged in the main charge box (8) which is sleeved on the gas separation sleeve (3); and the piston top cover (4) is in threaded connection with the top of the casing (2). After the igniter (1) is ignited, the piston rod (5) is pushed by the generated gas to upward move; the bottom of the piston rod (5) passes through a ventilation hole of the gas separation sleeve (3); and the main charge (7) is ignited by high-temperature and high-pressure gas. The gas as a power source provides power for the equipment. By changing the length of the piston, the ignition time of the main charge can be controlled by the device more easily and accurately.

Owner:BEIJING MECHANICAL EQUIP INST

Powder fuel engine

InactiveUS7311065B2Internal combustion piston enginesBlasting cartridgesCombustion chamberEngineering

Owner:LIN YI HSIUNG

Internal-combustion engine of combustible powder

InactiveCN1916381BRich sourcesSolve the energy crisisInternal combustion piston enginesPowdered engine fuelsEngineeringInternal combustion engine

An internal-combustion engine using combustible powder as fuel consists of fuel material preprocessor, mixer, fuel jet and discharging processor. The said combustible powder is prepared from plant residues, coal or combustible wastes and additives.

Owner:陈丽君

A self-feeding dust explosion engine

ActiveCN106640356BRealize automatic feedingSimple mechanical structureInternal combustion piston enginesFuel supply apparatusCombustion chamberFuel tank

The invention discloses an automatic feed dust explosive type motor, and belongs to the field of power plants. The automatic feed dust explosive type motor comprises a fuel tank, a feed compartment and a piston, wherein the fuel tank delivers feed to a combustion chamber through a feeding device, one end of the feed compartment is communicated with the feeding device, the other end of the feed compartment is communicated with the combustion chamber through a feed inlet, a cavity of the feed compartment is internally provided with a feed stopping ball, the top of the piston is provided with a thimble, the thimble is matched with the feed stopping ball to make dust fuel enter the combustion chamber, and the piston is matched with vent holes in the combustion chamber to control combustion emission to be exchanged with external gas. According to the technical scheme, through the coordination among the feed compartment, the feed stopping ball and the thimble, automatic feed towards the combustion chamber is achieved; in addition, the feed can be directly mixed with air in the combustion chamber, and the automatic feed dust explosive type motor is simple in structure and stable in performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

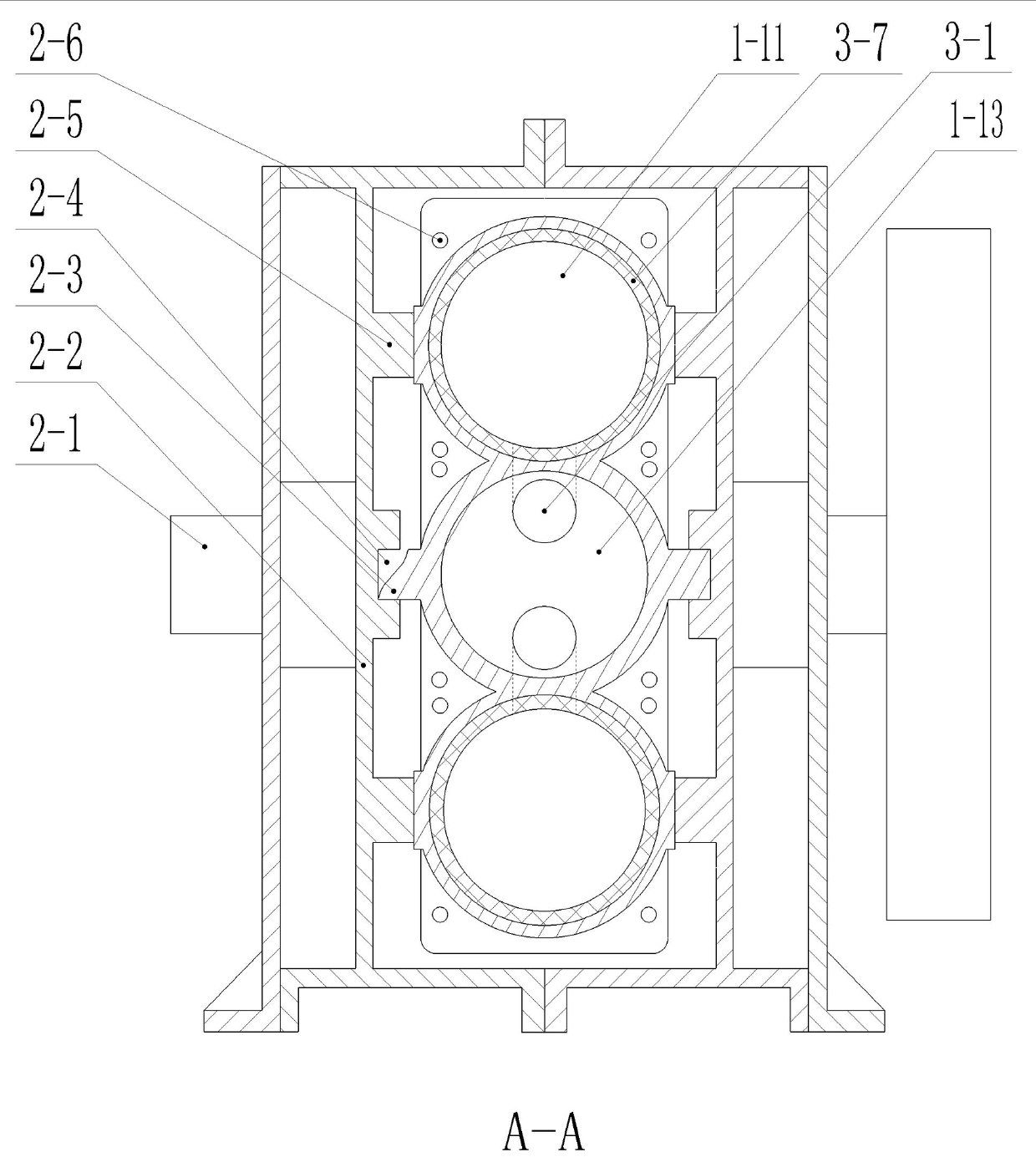

Gas-steam combined cycle isobaric variable displacement sliding vane engine

ActiveCN105952526BImprove mechanical efficiencyImprove efficiencyInternal combustion piston enginesGas turbine plantsCombustorCombustion chamber

The invention discloses a fuel gas-steam combined cycle equal-pressure variable capacitance slide piece rotor engine, and the engine is similar to an ideal variable high-efficiency combustion gas turbine. A stator shaped like an involute curved surface, a cylindrical rotor, a rotor shaft, a rotor cover, a slide piece assembly, a side cover and a combustor form a basic acting system. The stator, the rotor, the side cover and a slide piece enable the interior to be divided into an air gradual compression chamber (like multistage compression) and a gradual expansion chamber (multistage expansion) which is large in size and acts through fuel gas after combustion. During operation, the rotor rotates to inhale air from an air inlet, carries out gradual compression while the slide piece moves, and enables air to enter the combustor from a compressed air outlet and to be mixed with fuel gas. The gas absorbs heat to expand in an equal pressure manner. Because the compression area of an expansion chamber slide piece is larger than the compression area of a compression chamber slide piece by several times and the pressure intensities are equal, the thrust at the expansion chamber side is greater than the resistance of the compression chamber by several times, an external acting force moment is formed, and an equal-pressure expansion work is done. The expanded gas is divided by the slide piece in the expansion room, and the size of the expanded gas becomes large in operation, and then an adiabatic expansion work is done.

Owner:钱百成

Combustion chamber of solid fuel internal combustion engine

InactiveCN114183234AHigh thermal efficiencyInternal combustion piston enginesPowdered engine fuelsCombustion chamberExhaust valve

The invention relates to the field of internal combustion engines, and provides a combustion chamber of a solid fuel internal combustion engine, which comprises a shaft baffle and a shell, a round hole is formed in the shell, a worm penetrates through the round hole in the shell and the shaft baffle, the shaft baffle is connected to the shell through a bolt, a round hole is formed in the shell, a shaft penetrates through the round hole in the shell, and a worm gear is fixedly connected to the shaft. A feeding port, an air outlet and an air inlet are formed in the shell, and the feeding valve is characterized in that the feeding valve cam and the exhaust valve cam are fixedly connected to the shaft, the feeding valve plunger is installed in the feeding valve body, the feeding valve reset spring is arranged between the feeding valve plunger and the feeding valve body in a sleeved mode, and the feeding valve body is provided with a feeding valve outlet and a feeding valve inlet. The exhaust valve plunger is installed in the exhaust valve body, the exhaust valve reset spring is arranged between the exhaust valve plunger and the exhaust valve body in a sleeved mode, solid fuel can be sucked into a combustion chamber, and the heat efficiency of an internal combustion engine is improved.

Owner:杜淑霞

Dust recovery explosion type engine

InactiveCN105464793AEfficient recyclingEfficient use ofInternal combustion piston enginesPowdered engine fuelsDust explosionFlywheel

The invention relates to a dust recovery explosion type engine. The dust recovery explosion type engine is structurally characterized in that a cavity is formed in an engine body and forms a dust explosion chamber; a spark plug is arranged in the dust explosion chamber; a piston is arranged in the cavity and connected with a centrifugal pendulum flywheel through a connecting rod; an air suction port and an exhaust port which are communicated with the outside are formed in the upper portion of the cavity; and opening and closing mechanisms are arranged on the air suction port and the exhaust port respectively and connected with a driving device. By means of the dust recovery explosion type engine, various explosion accidents or harms to the body or other influences caused by dust in the production process can be reduced, and dust can be effectively recycled and effectively utilized.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Popular searches

Silencing apparatus Propulsive elements Engine cooling apparatus Nitrated pentaerythritol explosive compositions Nitrated acyclic/alicyclic/heterocyclic amine explosive compositions Pressure gas generation Pulverulent fuel combustion burners High pressure gas fuel injection Low pressure fuel injection Fuel injection with sensors

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com