Solid-fuel internal combustion engine

A solid fuel, internal combustion engine technology, applied in the direction of internal combustion piston engine, combustion engine, powder engine fuel, etc., can solve problems such as failure to work normally, internal combustion engine damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

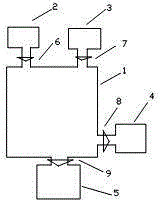

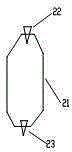

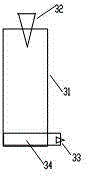

[0019] The invention consists of a combustion chamber 1, an air intake system 2, a feed system 3, a work system 4, and a slag discharge system 5. The combustion chamber 1 has a fixed volume, an igniter and a solid-gas separation device inside. The intake system 2 is connected to the combustion chamber 1 via an intake valve 6 . The feed system 3 is connected to the combustion chamber 1 through a feed valve 7 . The work system 4 is connected with the combustion chamber 1 through a work valve 8 . The slagging system 5 is connected with the combustion chamber 1 through the slagging valve 9 . Among them, the working system 4 is a multi-stage leveling working system, the air intake system 2 is an axial air compression system coaxially linked with the working system, the feeding system 3 is an independent electric slurry continuous feeding system, and the combustion chamber 1 is the inner wall High temperature resistant alloy combustion chamber with fireproof and heat insulating co...

Embodiment 2

[0021] The invention consists of a combustion chamber 1, an air intake system 2, a feed system 3, a work system 4, and a slag discharge system 5. The combustion chamber 1 has a fixed volume, an igniter and a solid-gas separation device inside. The intake system 2 is connected to the combustion chamber 1 via an intake valve 6 . The feed system 3 is connected to the combustion chamber 1 through a feed valve 7 . The work system 4 is connected with the combustion chamber 1 through a work valve 8 . The slagging system 5 is connected with the combustion chamber 1 through the slagging valve 9 . Among them, the work system 4 is a multi-stage leveling work system, the intake system 2 is a multi-stage axial flow air compression system coaxially linked with the work system, the feeding system 3 is an independent electric slurry continuous feeding system, and the combustion chamber 1 It is a high-temperature-resistant alloy combustion chamber with a fireproof and heat-insulating coating...

Embodiment 3

[0023] The invention consists of a combustion chamber 1, an air intake system 2, a feed system 3, a work system 4, and a slag discharge system 5. The combustion chamber 1 has a fixed volume, an igniter and a solid-gas separation device inside. The intake system 2 is connected to the combustion chamber 1 via an intake valve 6 . The feed system 3 is connected to the combustion chamber 1 through a feed valve 7 . The work system 4 is connected with the combustion chamber 1 through a work valve 8 . The slagging system 5 is connected with the combustion chamber 1 through the slagging valve 9 . Among them, the work system 4 is a multi-stage leveling work system, the intake system 2 is a multi-stage axial flow air compression system coaxially linked with the work system, the feeding system 3 is an independent electric slurry continuous feeding system, and the combustion chamber 1 It is a high-temperature-resistant alloy combustion chamber with a fireproof and heat-insulating coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com