Nano-iron powder fuel power generation method and device

A nano-iron powder and fuel power generation technology, which is applied in the direction of powdered engine fuel, noise reduction device, exhaust device, etc., can solve the problem of destroying the natural environment, achieve high reaction calorific value, strong activity, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

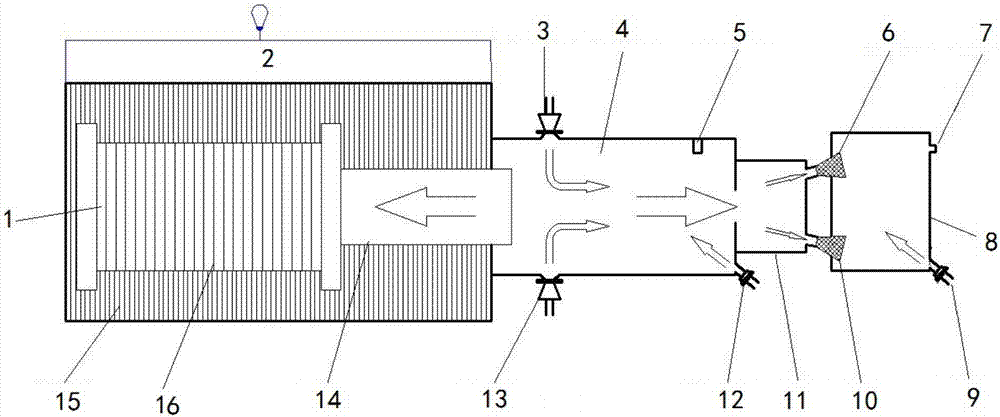

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0023] The core idea of the present invention is: to use nanometer iron powder as fuel, which can react violently with oxygen, has strong activity (nanoscale iron powder can burn at 250°C), high reaction calorific value, clean and pollution-free, and is environmentally friendly. The reaction product can be recycled and reused, and the energy is 2 to 3 times that of diesel and coal. It can replace the current non-renewable energy for power generation. It has huge advantages and belongs to the future new energy. The iron powder fuel that present embodiment selects is the iron powder that particle diameter is below 50nm, and specific surface area is 30m 2 / g, 99.9% purity, high reaction rate and strong activity.

[0024] Aluminum powder, while also a combustible powder, is not as ideal as iron powder. The main reasons are (1) The specific energy of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com