Turbocharged powder internal combustion engine

A turbocharger and turbocharger technology, applied in the field of machinery, can solve the problem of less than 50 years of mining life, and achieve the effect of large torque, convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

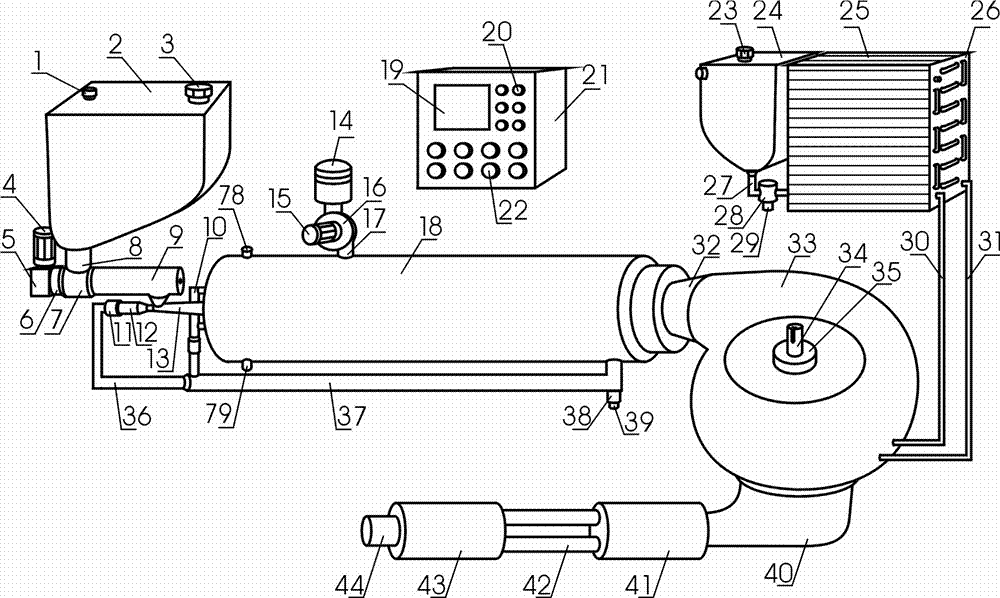

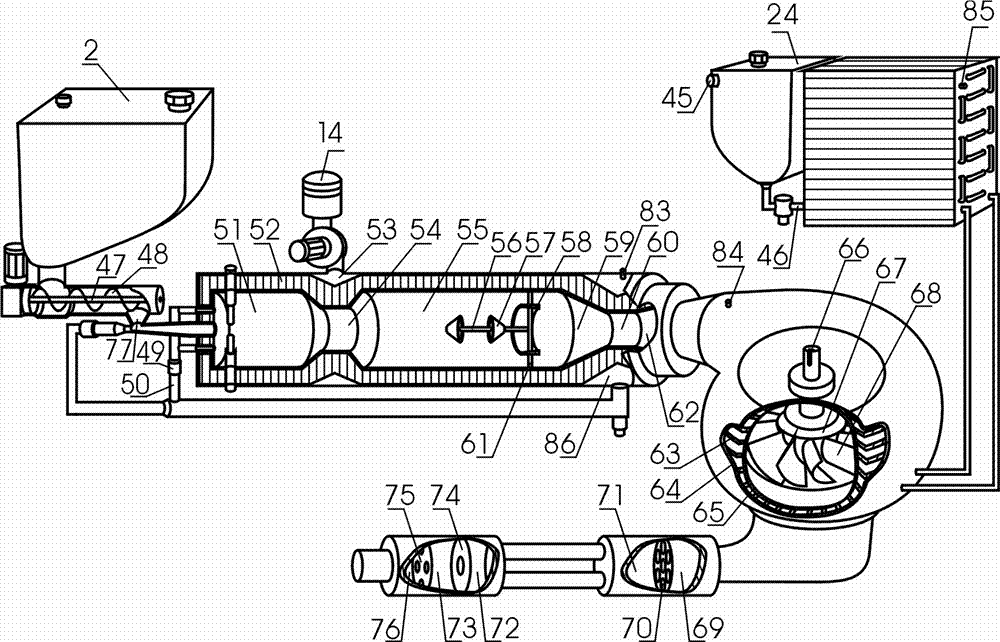

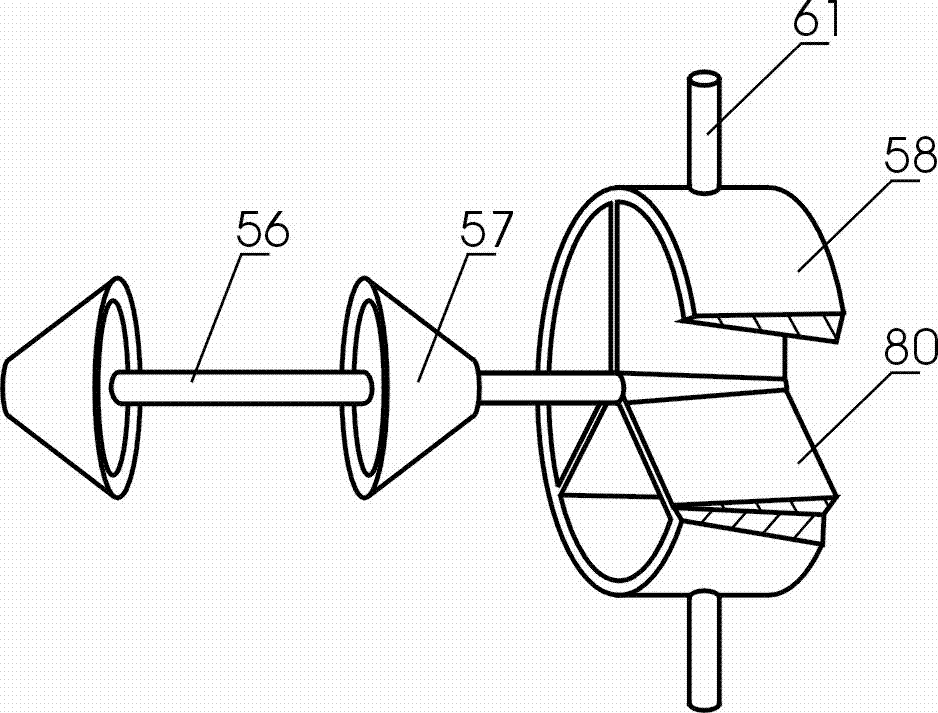

[0065] see Figure 1~4 Shown, a kind of turbocharged powder internal combustion engine is by fuel tank 2, rotary feed pipe 9, fuel spray barrel 13, combustion chamber 18, blower fan 16, combustion-supporting intake pipe 10,36,37,50, turbocharger 33 , an L-shaped exhaust pipe 40, a radiator 26, a water tank 24, and a control box 21; 13. The combustion air intake pipe 10 is connected to the combustion chamber 18; the combustion chamber 18 is provided with a fan 16, and the combustion chamber 18 is connected to the turbocharger 33 through a high-pressure gas joint 32; the L-shaped exhaust pipe 40 is connected to the turbocharger The water tank 24 is connected with the radiator 26 through the water tank water pipes 27, 46, the pressure relief solenoid valve 28 is connected with the radiator 26, and the radiator 26 is connected with the turbocharger 33 through the radiator water pipes 30, 31; the control box 21 Built-in control circuit board.

[0066] The fuel tank 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com