Dust recovery explosion type engine

A technology of dust recovery and dust explosion, which is applied in the direction of powdered engine fuel, engine components, combustion engines, etc., can solve the problems of dust explosion accidents and losses, and achieve the effect of reducing explosion accidents or harming the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

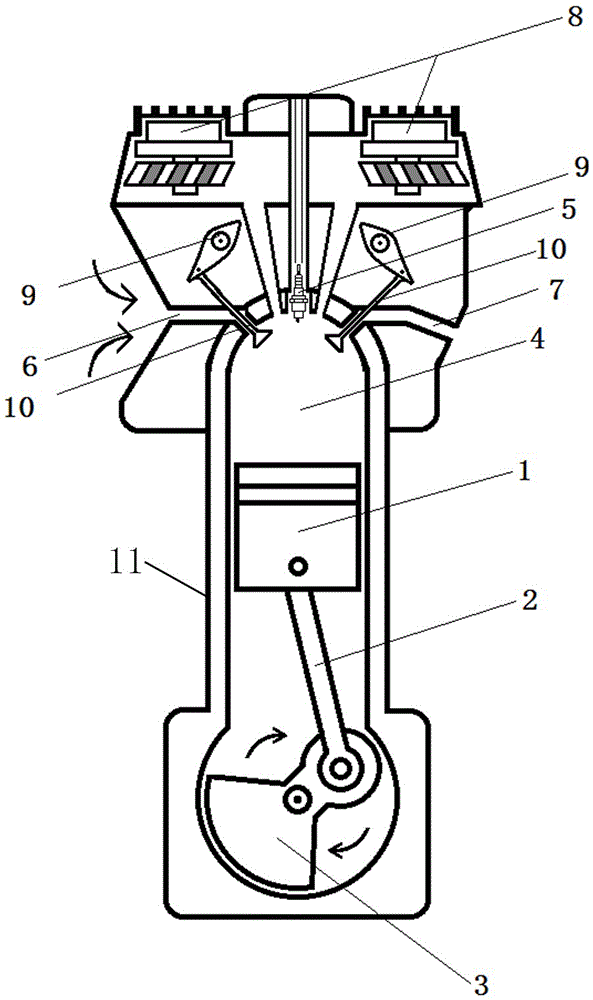

[0013] As shown in the figure, in the dust recovery explosive engine, the inside of the body 11 is a cavity, the cavity forms a dust explosion chamber 4, a spark plug 5 is arranged in the dust explosion chamber, a piston 1 is arranged in the cavity, and the piston is connected with a connecting rod 2. Centrifugal pendulum flywheel 3, the upper part of the cavity is respectively provided with suction port 6 and exhaust port 7 communicated with the outside world, the suction port and the exhaust port are respectively provided with opening and closing mechanism, and the opening and closing mechanism is connected with the driving device.

[0014] The opening and closing mechanism includes a rocker arm 9 and a regulating valve 10, the rocking arm is arranged on the upper part of the body, one end of the regulating valve is connected with the rocking arm, and the other end of the regulating valve extends into the cavity through the suction port or the exhaust port Inside; the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com