Piston movement and ignition separated gas power device

A technology of gas power and piston movement, which is applied to internal combustion piston engines, powdered engine fuels, fuel oil systems, etc. It can solve the problems of difficult control of the ignition time of the main charge, complex structure, and single function of the gas power device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

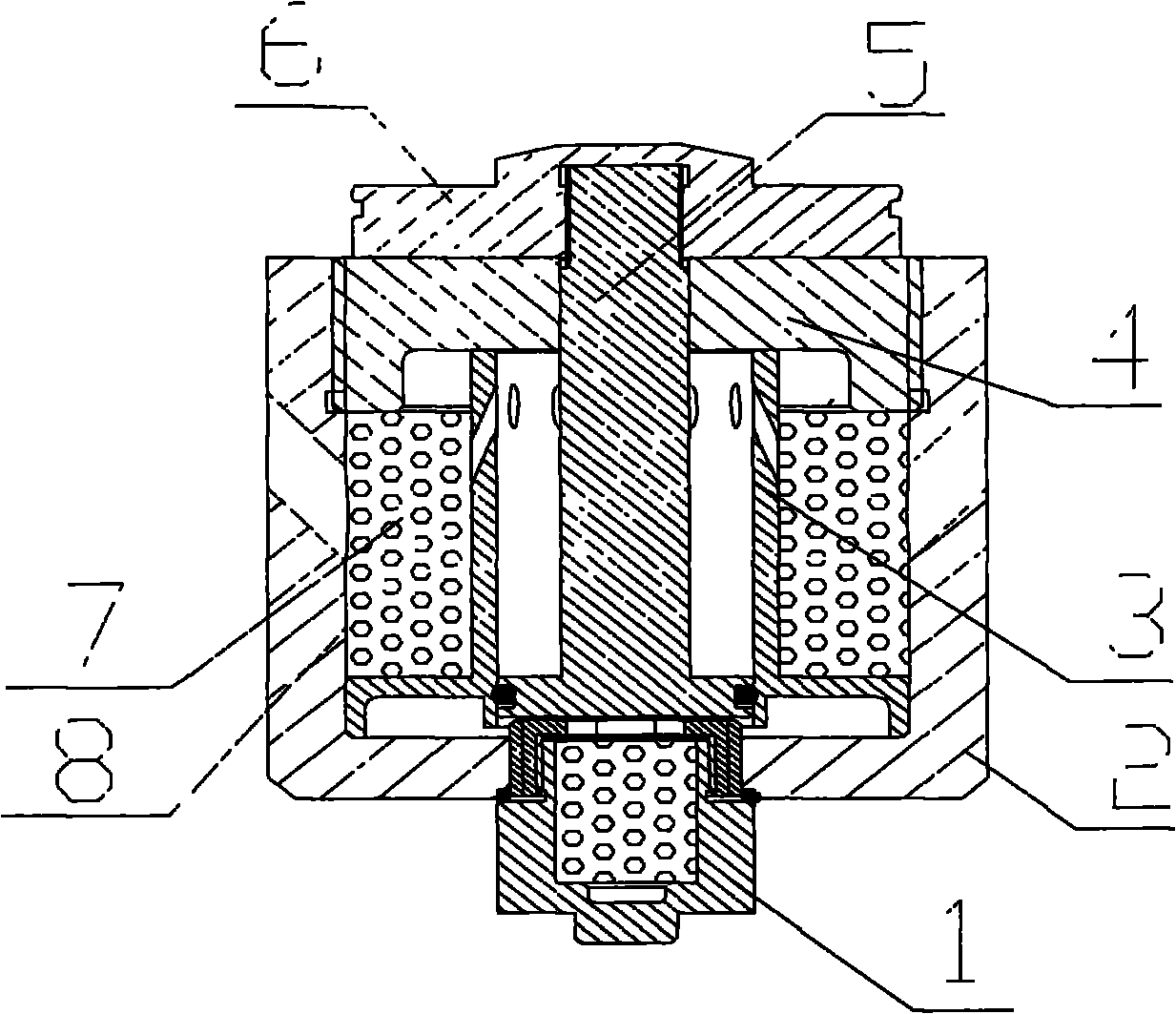

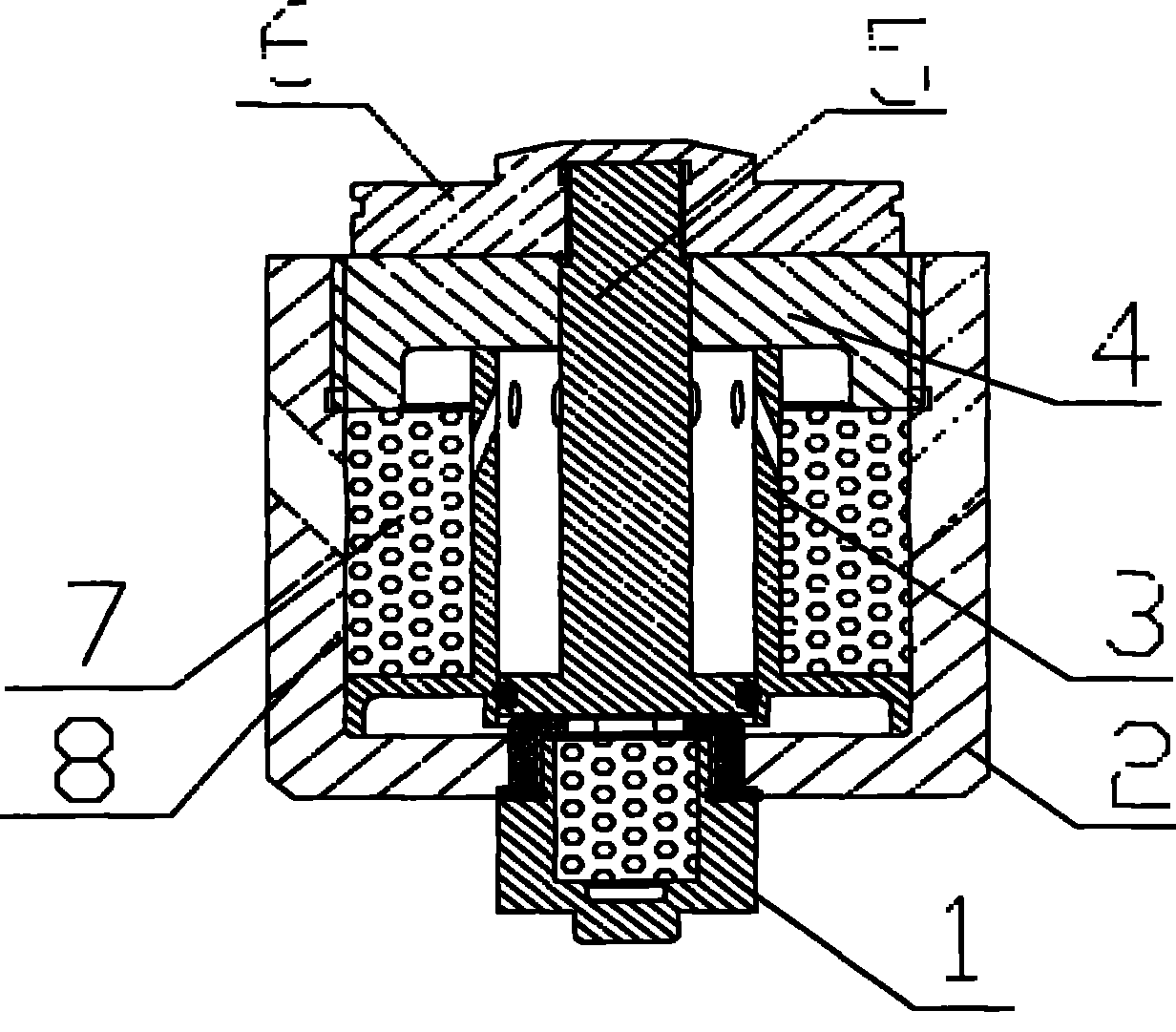

[0009] A gas power device with piston movement and ignition separated, comprising: igniter 1, casing 2, piston top cover 4, piston rod 5, piston head 6, main charge 7, main charge cartridge 8, and also includes: gas Separate sleeve 3. The igniter 1 is screwed on the shell 2, the gas separation sleeve 3 is placed in the inner cavity of the shell 2, the gas separation sleeve 3 and the bottom of the inner wall of the shell 2 are sealed with silicon rubber, the piston rod 5 is placed in the gas separation sleeve 3, The main charge 7 is placed in the main charge cartridge 8, the main charge cartridge 8 is set on the gas separation sleeve 3, the piston top cover 4 is threaded on the top of the casing 2, and the piston head 6 is threaded on the piston rod 5 .

[0010] After the igniter 1 is ignited, a high pressure is formed in the volume between the bottom of the piston rod 5 and the gas separation sleeve 3, pushing the piston rod 5 and the piston head 6 to move upward. With the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com