Solid fuel internal-combustion engine

A solid fuel, internal combustion engine technology, applied in the field of internal combustion engines and water turbines, can solve problems such as ignition difficulties, fuel injector wear, and corrosive fuels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

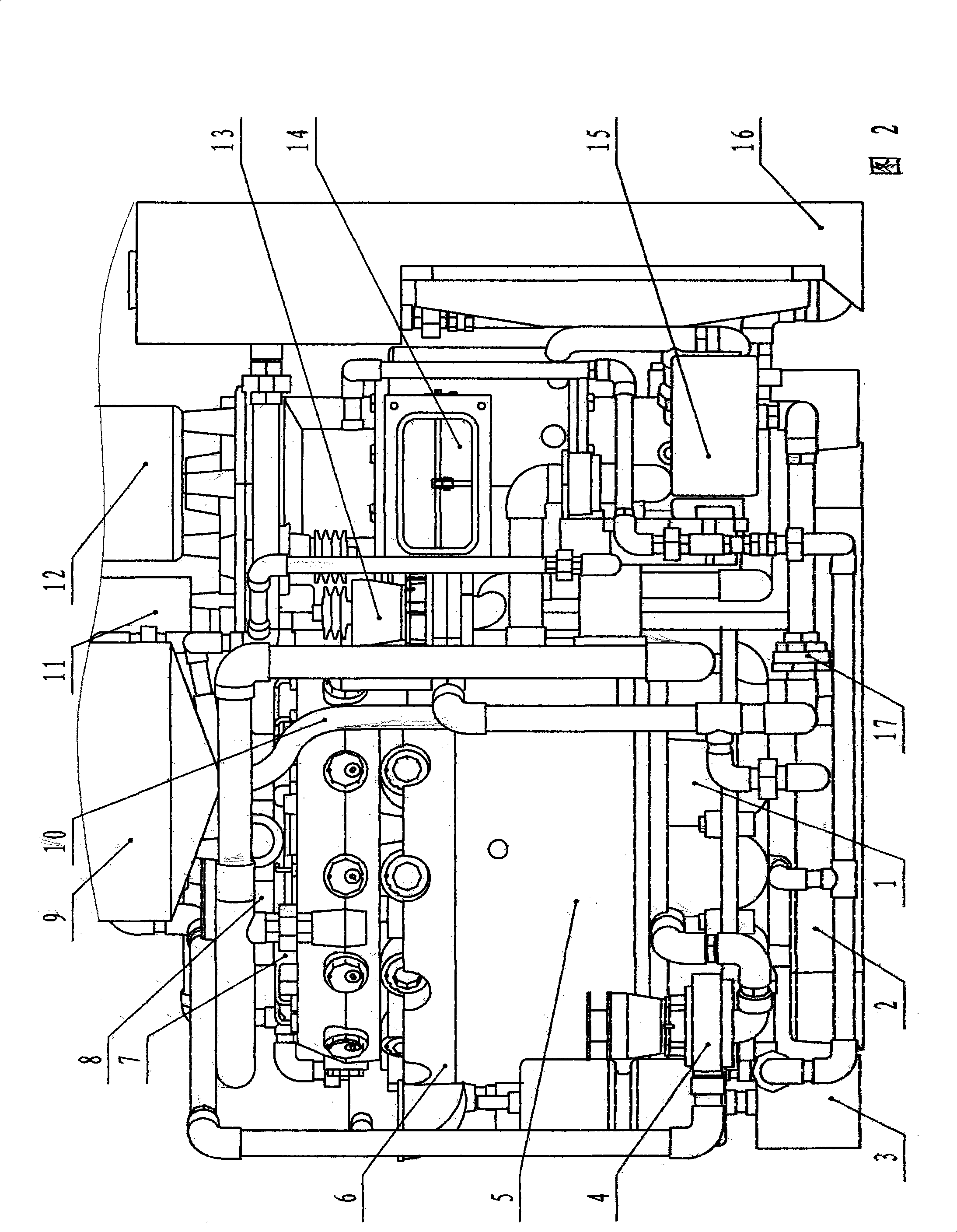

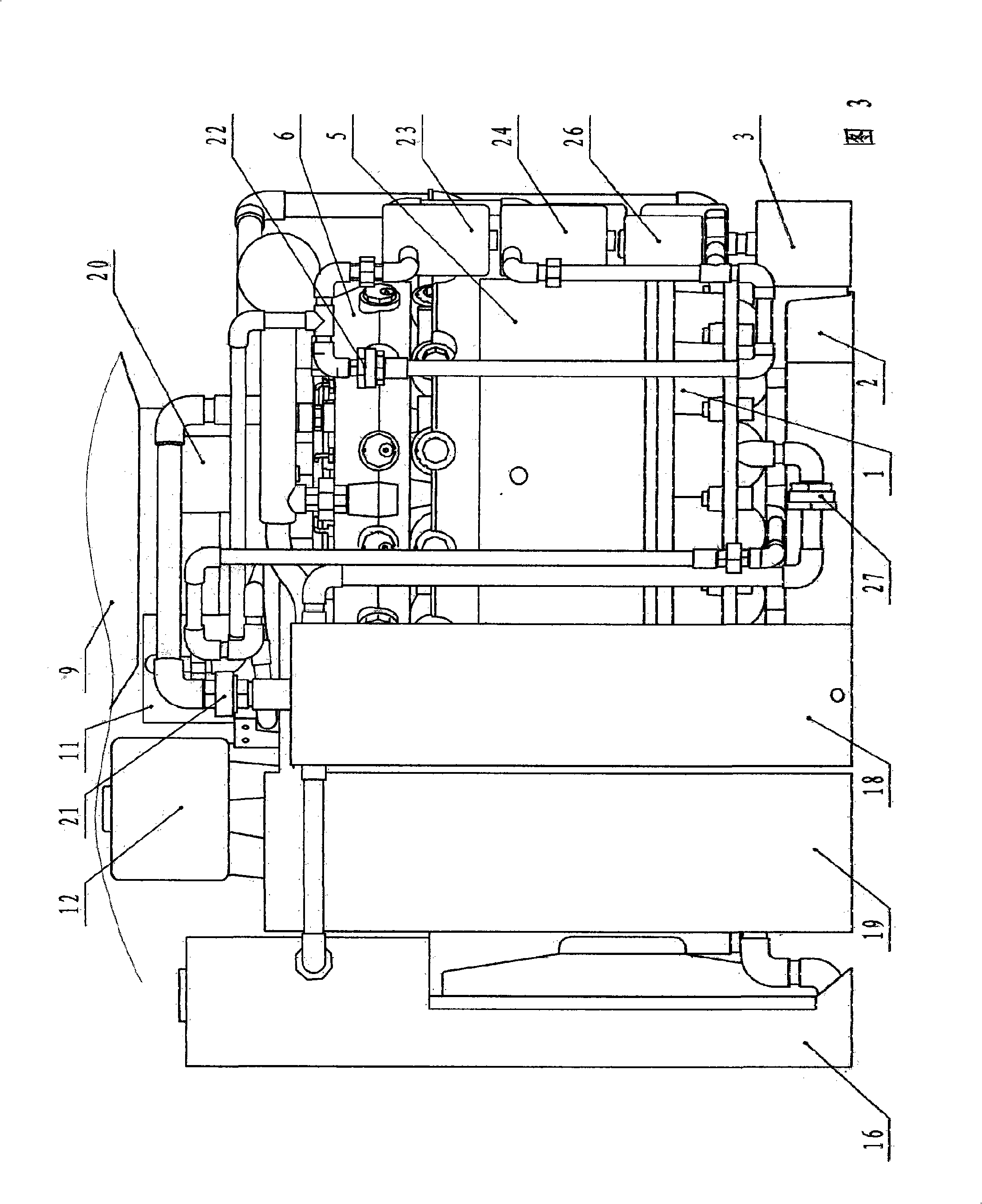

[0008] With reference to the accompanying drawings, the "specific implementation" of the "design method, working process, and structural form of the solid fuel internal combustion engine" proposed in the "summary of the invention" in conjunction with the "illustration of the drawings" is as follows:

[0009]1. A solid fuel internal combustion engine that can conveniently use cheap fuels such as solid fuel powder and liquid oil, including a cylinder head (6), a camshaft component (29), a water cylinder block (28), a water turbine (1), a solid fuel Pump (15), fuel injection pump (7), accessory gearbox (8), air compressor (14), circulating water pump (13), cooling water radiator (16), cooling water purification filter (18), lubricating oil tank (3), lubricating oil pressure oil pump (37), is characterized in that: a: cylinder head (6) is combined by pre-combustion chamber (34) and combustion chamber (33), the pre-combustion chamber (34) and the integral casting The outer circumfe...

example 1

[0021] A: Parameter estimation of the compressor:

[0022] Speed: 1680 revolutions per minute Suction impulse coefficient: 0.95 Variable index: 1.3 Slider number: 10 Slider angle: 15 degrees

[0023] First stage compressor: Intake pressure: 0.1Mpa Exhaust pressure: 0.5Mpa Rotor diameter: 201.6mm Rotor length: 236mm Ellipse cylinder diameter: 256×200mm Maximum base circle volume: 435.5Cm 3 Volumetric efficiency: 0.832 Displacement per minute: 12.173m 3 Efficiency: 0.832

[0024] Second stage compressor: Intake pressure: 0.5Mpa Exhaust pressure: 2.25Mpa Rotor diameter: 104.5mm Rotor length: 120mm Ellipse cylinder diameter: 125.8×104mm Maximum base circle volume: 41.9Cm 3 Volumetric efficiency: 0.7077 Displacement per minute: 12m 3 Efficiency: 0.7

[0025] B: Parameter estimation for solid fuel internal combustion engines:

[0026] Air pressure in pre-combustion chamber and combustion chamber: 2.0MPa, air-fuel ratio: 1.2, combustion chamber volume: 139Cm 3 Gas consumpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volumetric efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com