Pneumatic filling method and system for powder particles

A powder particle and filling system technology, which is applied in the direction of fuel system, powdered engine fuel, engine components, etc., can solve the problems of dust explosion, lower filling efficiency, environmental pollution, etc., and achieve the effect of avoiding waste and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

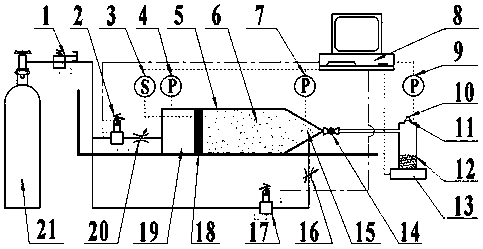

[0016] A powder particle pneumatic filling system of the present invention, such as figure 1 Shown, comprise material storage box 5, gas cylinder 21 and powder box 12, material storage box 5 is columnar body, and its front end is conical shape, and coaxial sleeve is provided with piston 18 in it, and material storage box 5 is internally axially The top is divided into two independently set fluidizing chambers 15 and driving chambers 19 from front to back. The front end of the fluidizing chamber 15 is provided with a powder outlet, which is connected to the powder box 12 with a pipeline, and a ball valve 14 is arranged at the powder outlet; The front end cone of the fluidizing chamber 15 and the rear end of the driving chamber 19 are all connected to the gas cylinder 21; the gas in the gas cylinder 21 is used to fill the driving chamber 19 and the fluidizing chamber 15, and the The gas drives the piston 18 to push the powder particles 6 in the fluidization chamber 15 to move fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com