Gas-steam combined cycle isobaric variable displacement sliding vane engine

A rotary engine and sliding vane technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of poor low-speed performance, insufficient efficiency, and low-speed low-efficiency gas turbines, and achieve high power ratio, low production cost, The effect of high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

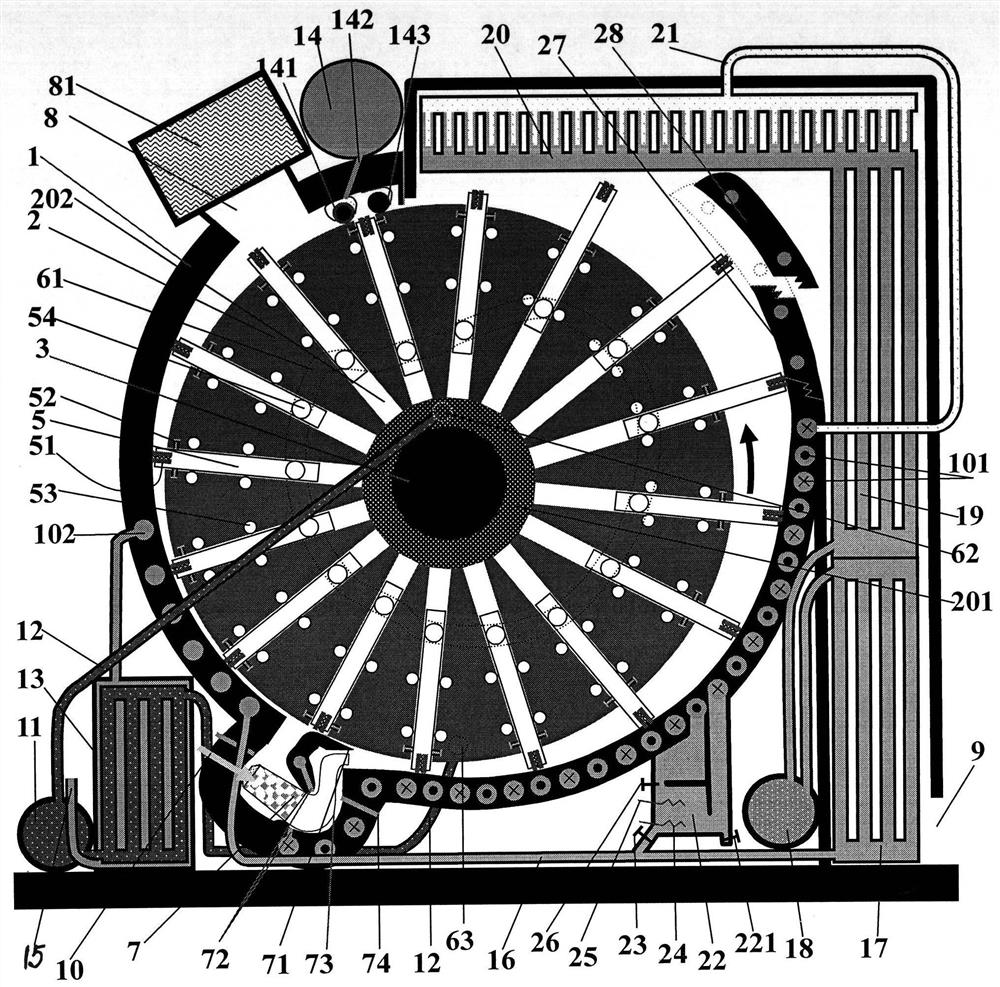

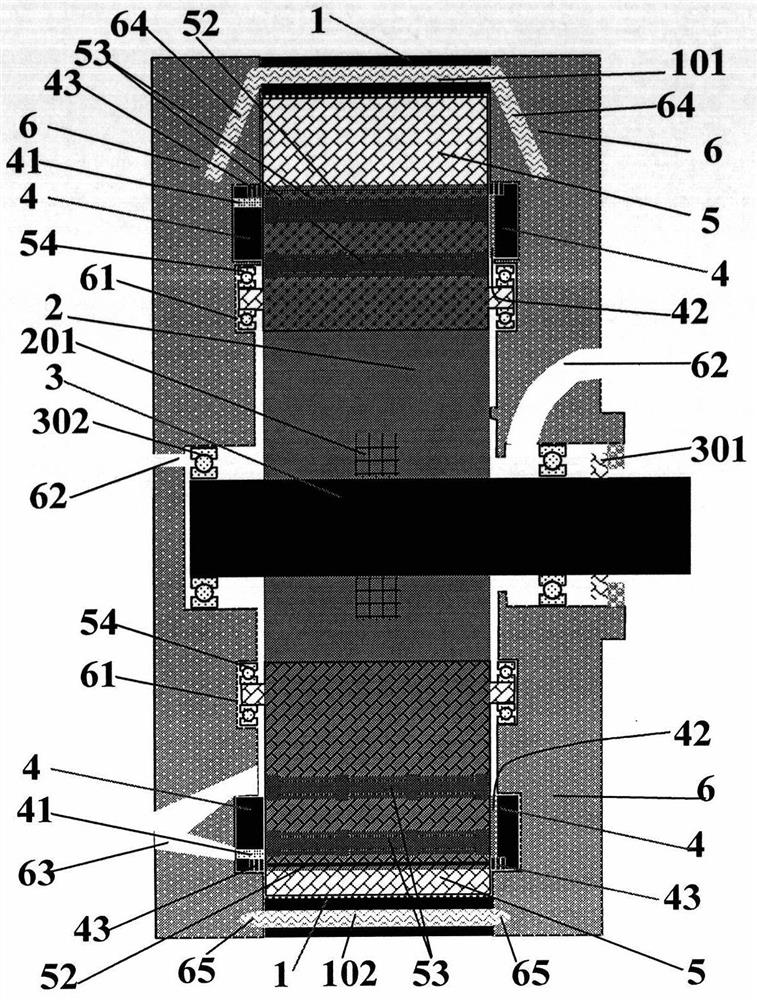

[0040] Among the figure, stator (1), rotor (2), rotor shaft (3), rotor cover (4), sliding vane assembly (5), side cover (6), combustion chamber (7) etc. form the basic work system. The cylindrical rotor (2) with the sliding vane assembly (5) having the vane groove (202) is installed on the rotor shaft (3) with splines, and the middle part of the shaft hole of the spline shaft on the rotor is installed There is a ring groove (201) connecting the sliding vane groove to allow the gas and liquid in the sliding vane groove to circulate freely, so as to avoid compressing the gas when the sliding vane moves up and down in the sliding vane groove, and waste energy; the rotor (2) is fixed by the rotor cover (4). The structure is strengthened to form the rotor assembly; the rotor cover (4) has an oil-gas sealing ring (43) which is used for sealing between the rotor (3) and the side cover (6) and is the same as the piston ring, and the rotor cover (4) on one side There are also lubricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com