Initiating explosive actuator adopting low detonation velocity charging to reduce incidental impact and pollution

A pyrotechnic actuator and low detonation velocity technology, applied in the field of pyrotechnics, can solve problems such as ammunition and spacecraft structural deformation, impact harmful gas leakage, excess and pollutants, etc., to improve intrinsic safety and reduce incidental impact , or avoid the effect of incidental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

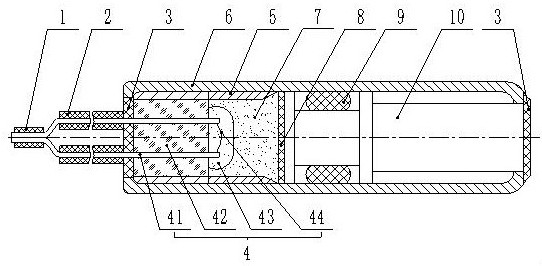

[0015] combine figure 1 , a pyrotechnic actuator that uses low detonation velocity charges to reduce incidental impact and pollution, consisting of a short-circuit sleeve 1, an electric ignition head 4, a reinforcing ring 5, a tube shell 6, a driving charge 7, a gasket 8, a sealing ring 9, Piston 10 and two insulating sleeves 2 constitute. Wherein electric ignition head 4 is made of electrode plug 42, ignition powder 43, bridge wire 44 and two wires 41, and wherein ignition powder 43 is lead trinitroresorcinol, or other weak priming powder, ignition powder, ignition powder 43 wrapped around the bridge wire 44 periphery. After a certain voltage pulse is applied to both ends of the bridge wire 44 , the bridge wire 44 will generate a large amount of heat in a short time to ignite the ignition powder 43 . One end of the two wires 41 is inserted into the electrode plug 42, and the other end is exposed on the outer end surface of the electrode plug 42 and extends out of the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com