Powder fuel engine

A technology for engines and fuels, applied in combustion engines, internal combustion piston engines, powdered engine fuels, etc., can solve problems such as high ash content, poor fluidity, and tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

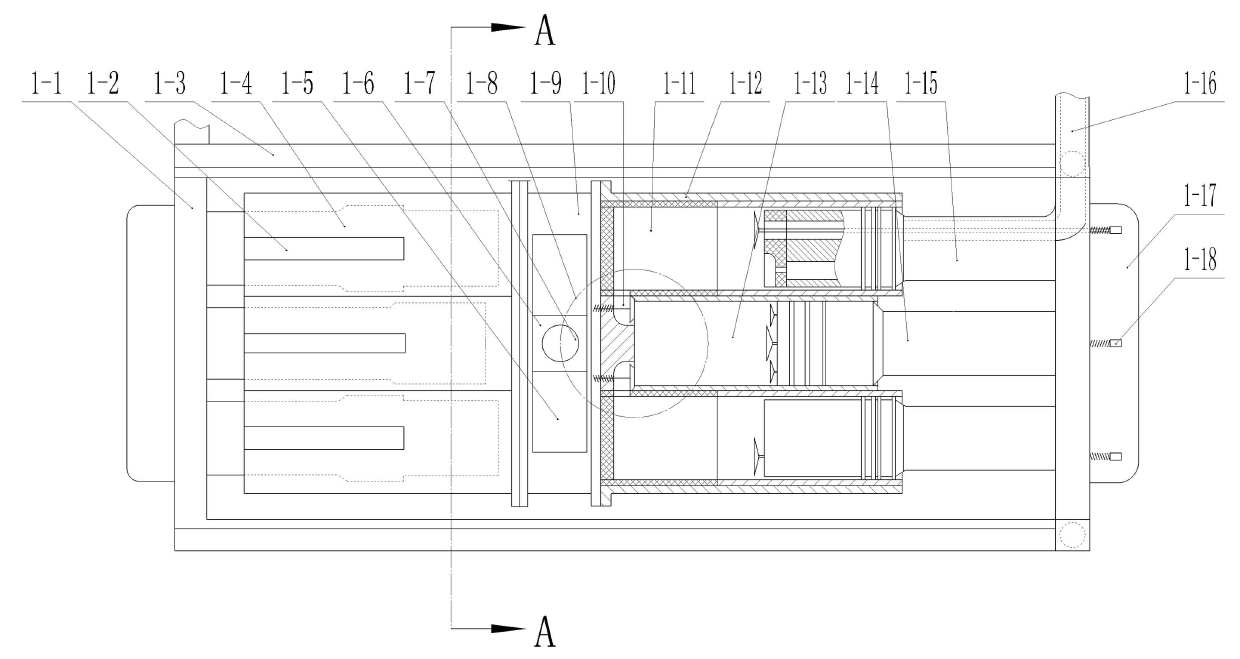

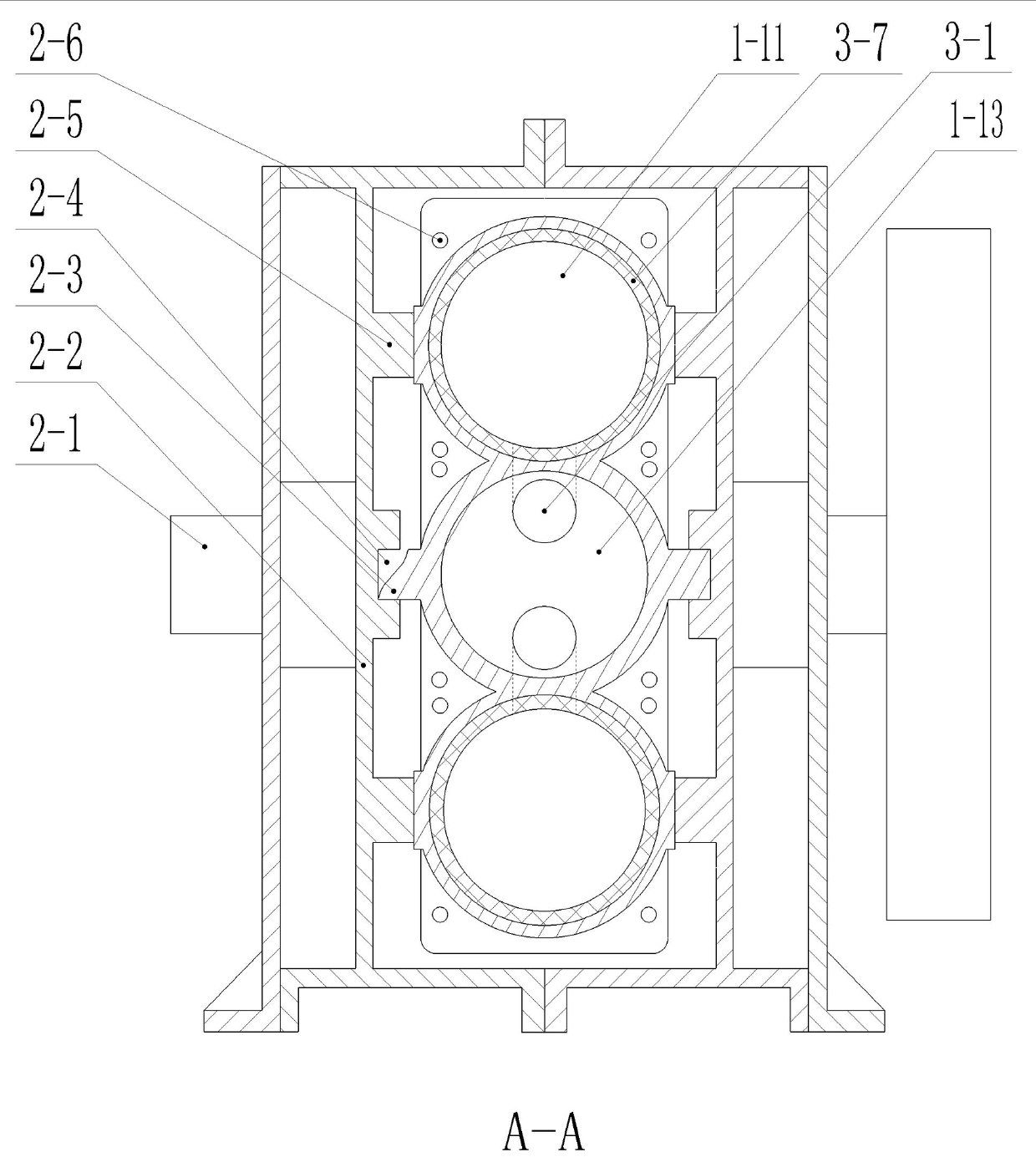

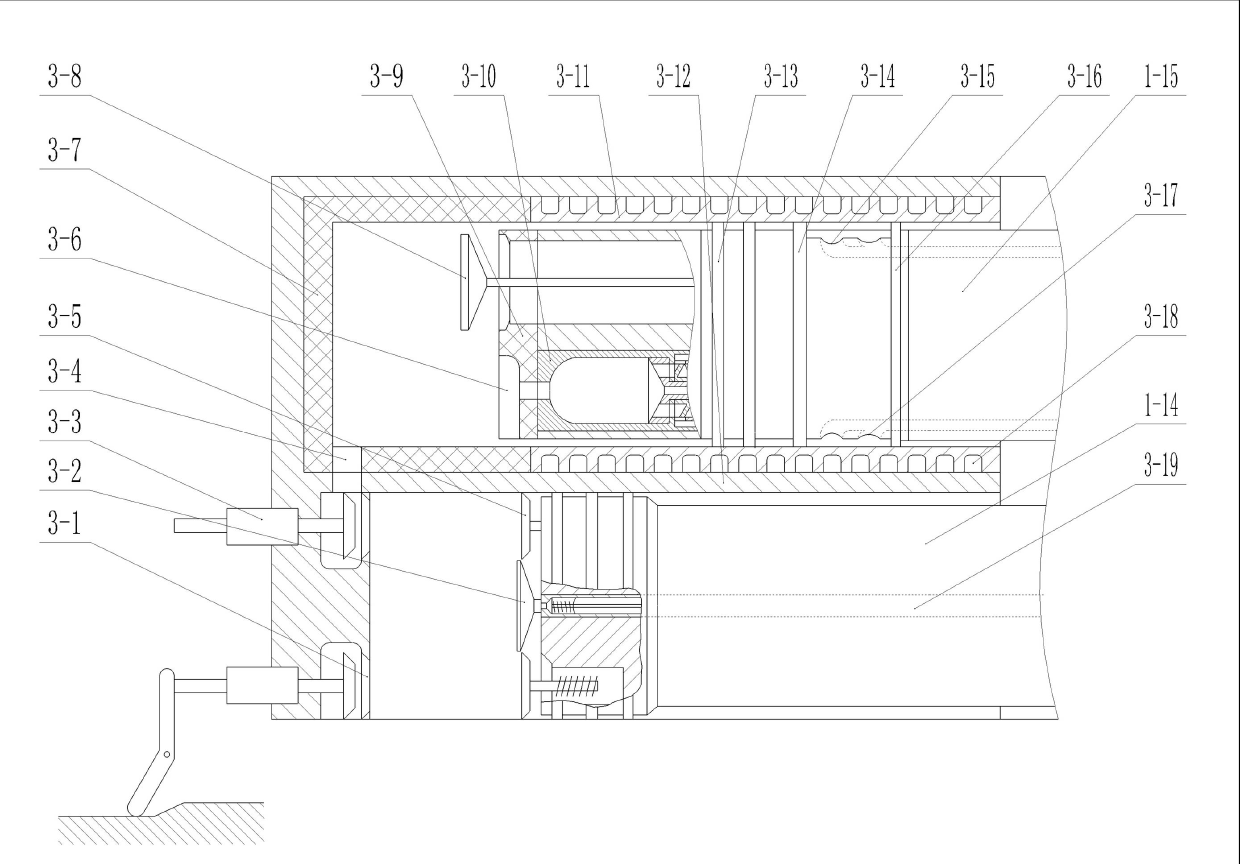

[0050] refer to figure 1 , figure 2 , a powder fuel engine, including a power system, a fuel supply system, an air supply system and an ash and tar removal system, the piston in the power system is fixedly connected to the body, the cylinder is connected to the power output mechanism, and the fuel supply in the fuel supply system The device 3-10 communicates with the power cylinder 1-11 in the cylinder, the air channel 3-4 in the air supply system communicates with the compression cylinder 1-13 in the cylinder, and the decoking ring 6-7 in the ash removal and tar removal system communicates with the Power cylinder 1-11 abuts against.

[0051] The power system includes a cylinder and a piston assembled therewith. The cylinder is a cylinder unit body, and the cylinder unit body includes a compression cylinder 1-13 and a power cylinder 1-11, and the compression cylinder 1-13 is connected to the power cylinder 1-11. 11 provides compressed air, the purpose is to implement split-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com